Electric equipment for railway vehicle

A technology for railway vehicles and electrical products, applied in locomotives, railway transportation, railway transportation, etc., can solve the problems of increased stress and deflection of the installation part, and achieve the effects of preventing mass increase, solving strength, and relaxing stress.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

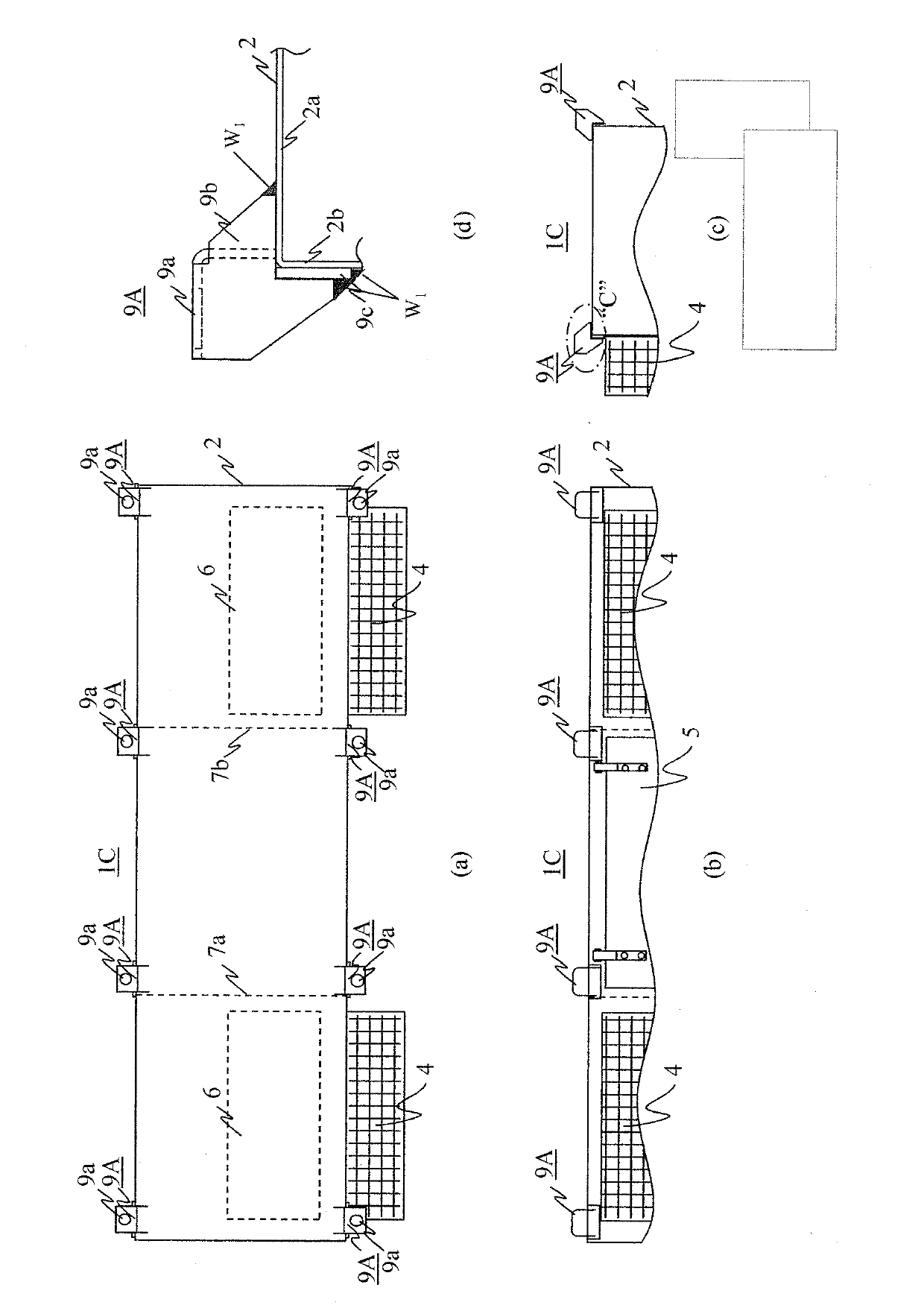

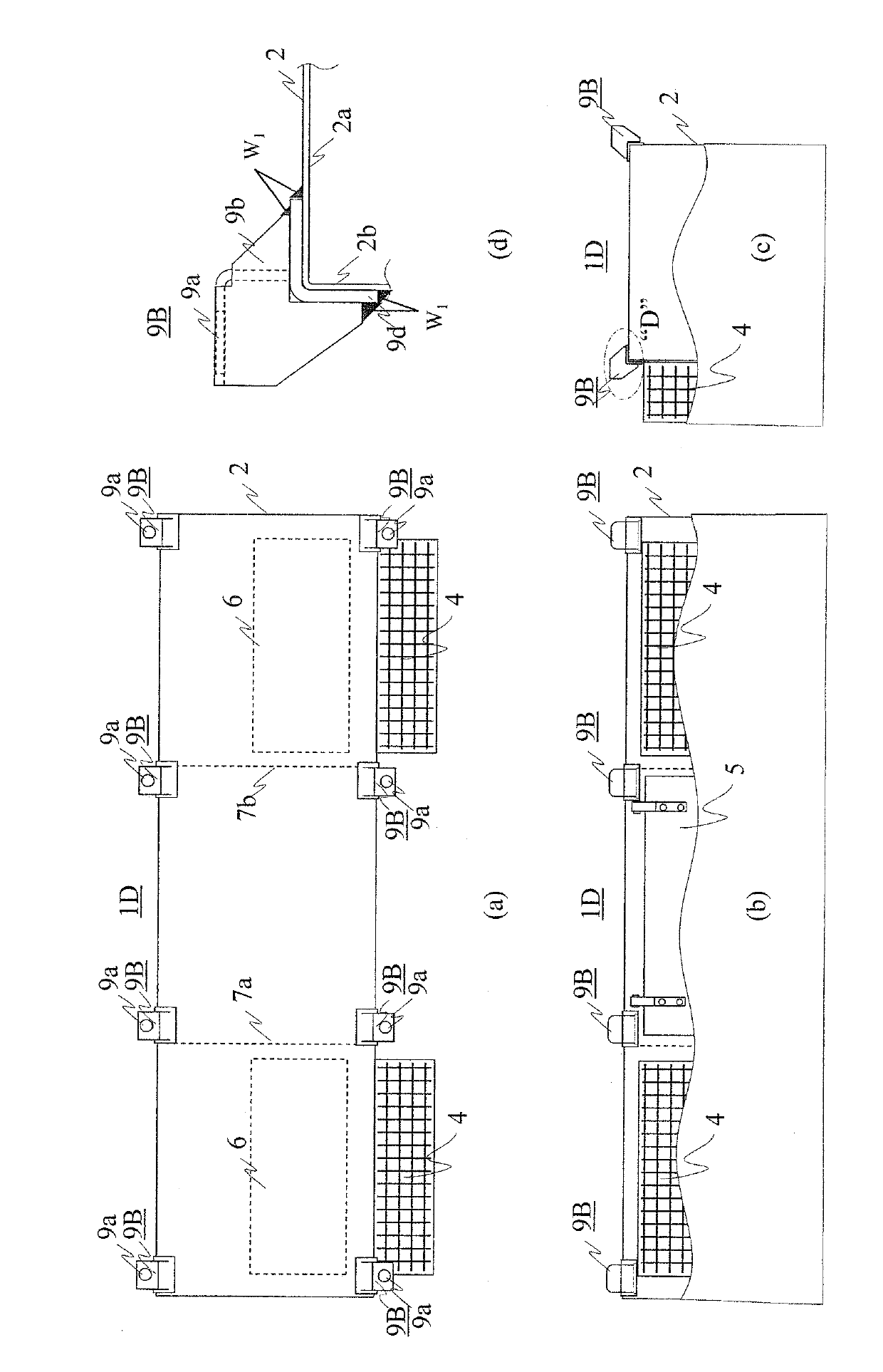

[0070] Below, use Figure 1 to Figure 4 , and an embodiment of an electrical product for railway vehicles to which the present invention is applied will be described. It should be noted that, in the following description, the same functional components are assigned the same symbols and repeated descriptions are omitted.

[0071] figure 1 It is a figure which shows the 1st embodiment of the electric product for railway vehicles of this invention, (a) is a top view, (b) is a front view, (c) is a right side view, (d) is C part enlargement of (c) picture. exist figure 1 in, with Figure 8 and Figure 9 The difference lies in the structure of the suspension equipment, others with Figure 8 and Figure 9 same.

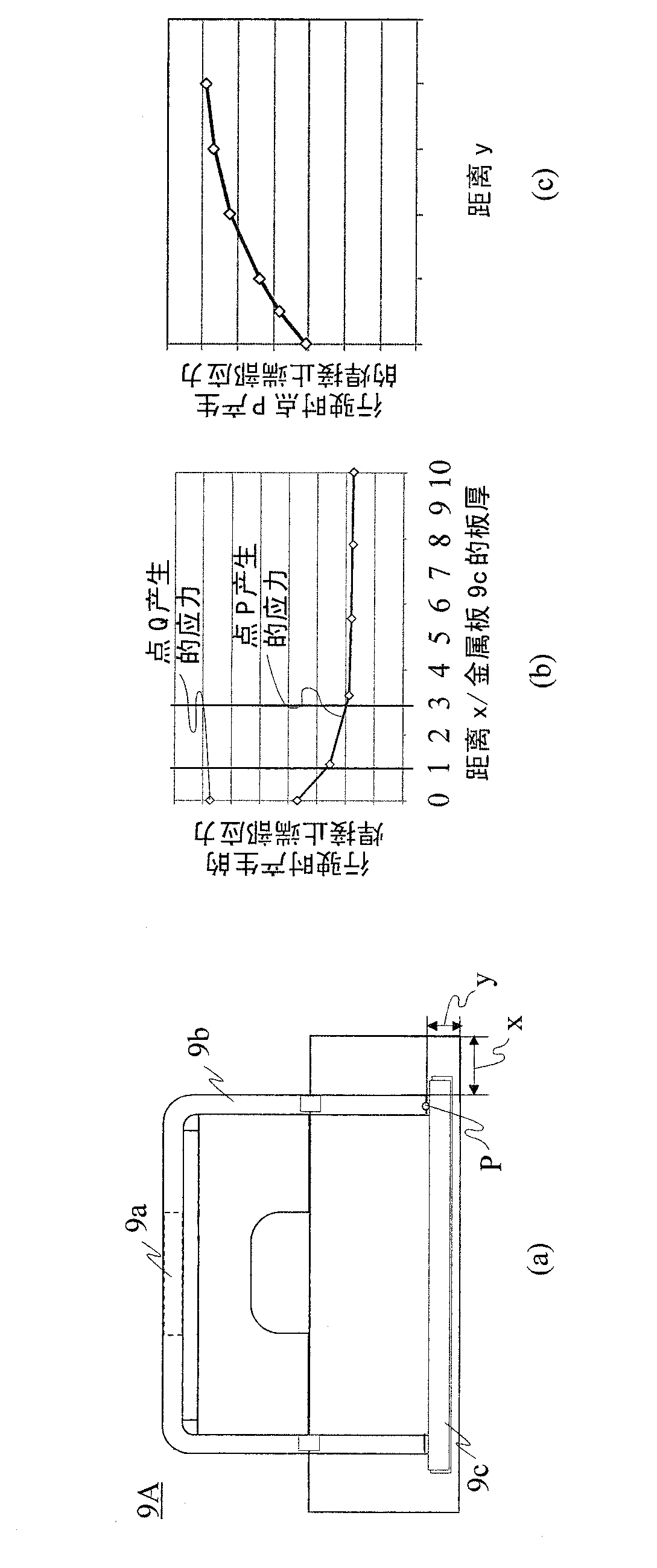

[0072] The hanger 9A is comprised from the hanger 9b and the metal plate 9c. Hanger 9b in figure 1 In the front view of (b), the metal plate is bent into an inverted U shape, has bent mounting portions on both sides and an upper portion connecting the mounting p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com