Method for improving aero-engine air injection reverse thrust efficiency

An aero-engine and engine technology, which is applied to the exhaust port of the power unit, affects the air flow through the surface of the aircraft, and the parts of the aircraft to achieve the effect of improving the propulsion efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

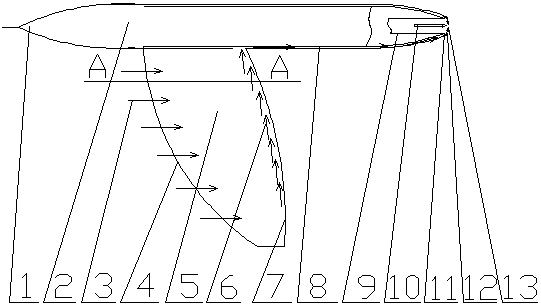

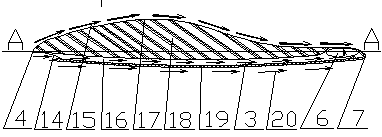

[0025] exist figure 1In the embodiment one shown in -3: the method for improving the jet reverse thrust efficiency of the aeroengine is to introduce the airflow from the lower side opening of the wing front edge 4, and these airflows are passed through the wing rear end air guide cavity 6 and fuselage air guide cavity 8 guide to the vicinity of the engine injection port 11 for ejection, when these air streams are injected near the engine injection port 11, they form an angle of 30°~89° with the engine hot gas flow 10 ejected from the engine injection port 11 The included angle makes these air flows form a high-density "gas cushion" near the engine injection port 11, so that the air flow around the aircraft is sent to the vicinity of the engine injection port 11 and forms a "gas cushion" to improve the hot gas injection of the engine. While the reverse thrust efficiency also makes the airflow 20 flow rate and the flow velocity of the lower side of the wing greatly reduced, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com