Automatic steamer loading system and steamer loading method thereof

A fully automatic, steamer-loading technology, applied in transportation, packaging, loading/unloading, etc., can solve the problems of high labor intensity, high labor cost, and high technical requirements, and achieve the effects of difficult transportation, fast response, and flexible control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1)

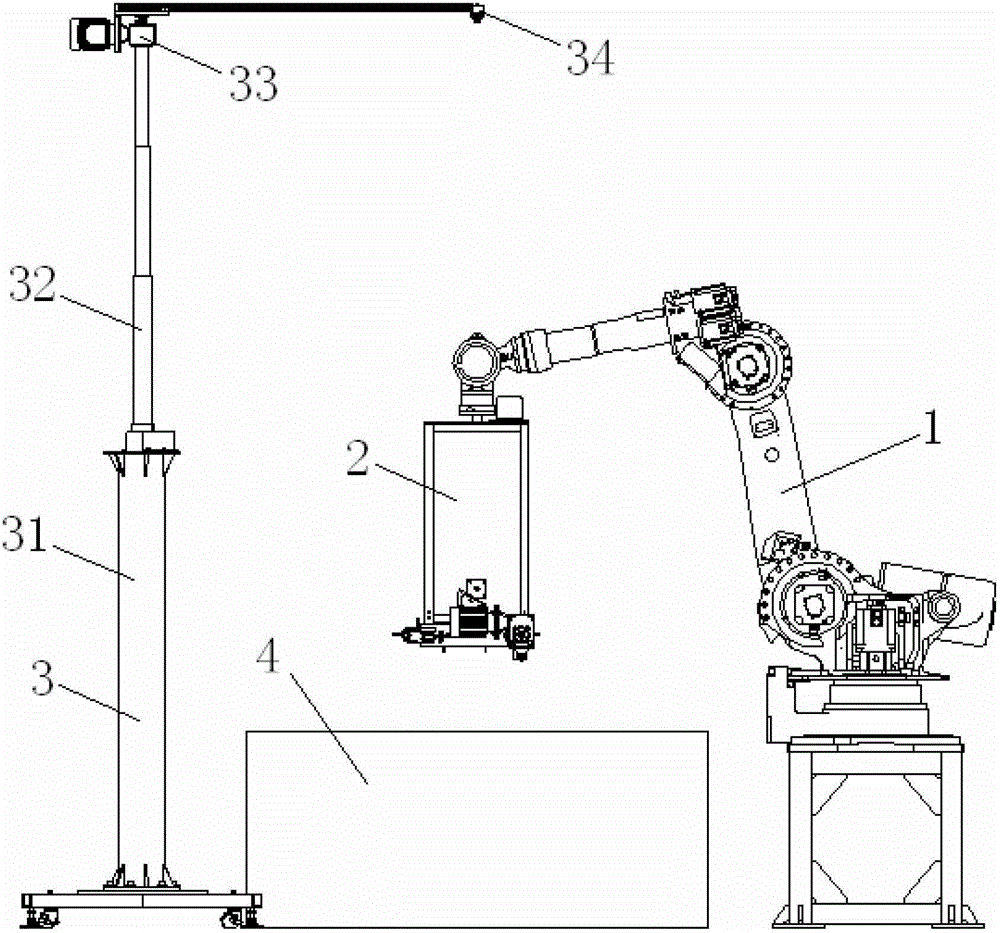

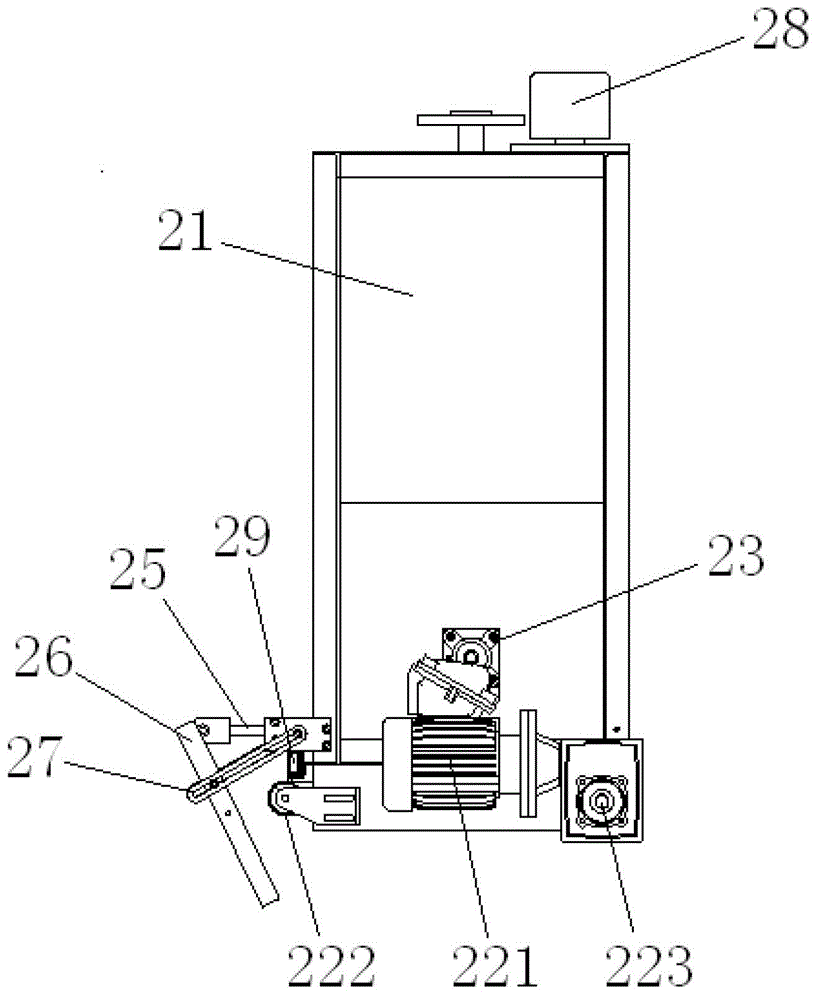

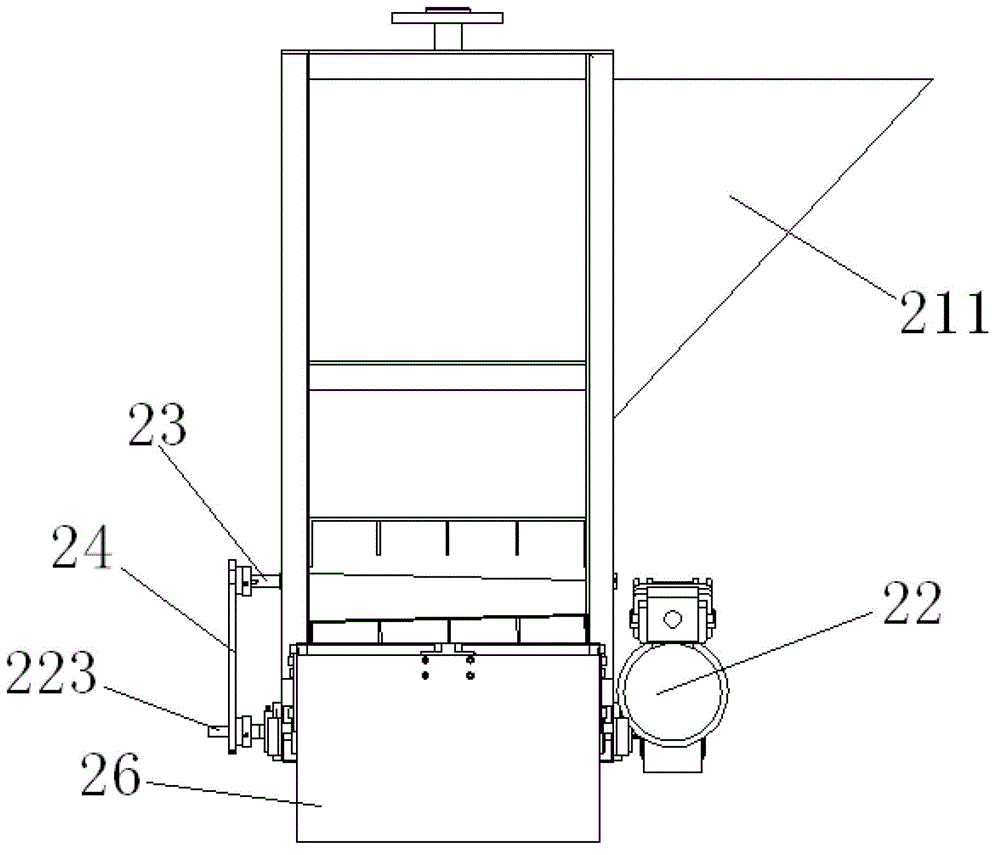

[0037] See figure 1 , The fully automatic retort loading system of this embodiment includes a multi-joint robot 1, a retort loading actuator 2, a retort loading visual measurement and control mechanism 3, a central control mechanism and a feeding mechanism.

[0038]The retort actuator 2 is fixed at the end of the multi-joint robot 1 and is located above the retort bucket 4 . The retort visual measurement and control mechanism 3 monitors the temperature and height of the material surface in the retort barrel 4 in real time. The central control mechanism receives the information collected by the retort visual measurement and control mechanism 3, and sends control information to the multi-joint robot 1 and the retort visual measurement and control mechanism 3. According to this control information, the multi-joint robot 1 controls the retort actuator 2 to carry out material spreading and replenishment. At the same time, this control information is fed back to the retort visual m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com