Low-temperature steel for large-line energy welding with yield ratio not more than 0.85 and production method of low-temperature steel

A technology for high-energy-input welding and low-temperature steel, which is applied to high-energy-input welding low-temperature steel with a yield ratio ≤ 0.85 and its production field, which can solve problems such as increasing manufacturing costs, reducing yield ratio, and instability. Achieve the effects of improving stability and safety, shortening manufacturing time, and excellent low-temperature toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention is described in detail below:

[0036] Table 1 is the value list of each embodiment of the present invention and comparative examples;

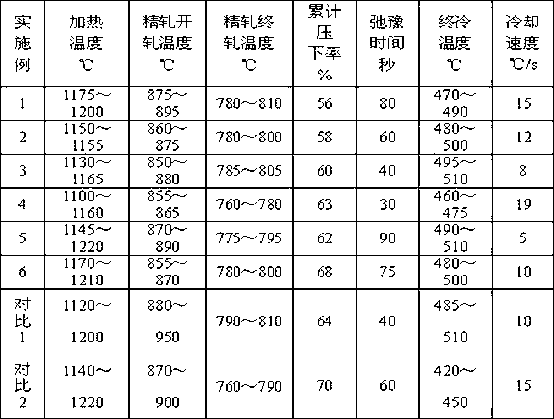

[0037] Table 2 is the main rolling process value list of each embodiment of the present invention and comparative examples;

[0038] Table 3 is the tempering process value list of each embodiment of the present invention and comparative examples;

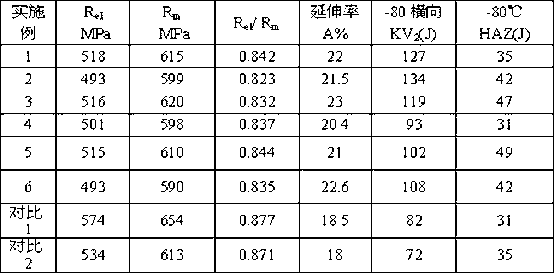

[0039] Table 4 shows the test results of the mechanical properties of the various examples and comparative examples of the present invention.

[0040] Each embodiment of the present invention is produced according to the following steps:

[0041] The steps are:

[0042] A method for producing high heat input welding low-temperature steel with a yield ratio ≤ 0.85, the steps of which are as follows:

[0043] 1) After desulfurization and smelting, it is continuously cast into billets;

[0044] 2) Heating the billet to 1100-1220°C;

[0045] 3) The surface of the slab i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield ratio | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap