Method for constructing wall pulling steel bars in frame column and structure thereof

A construction method and frame column technology, applied in the direction of building structure, structural elements, building components, etc., can solve problems such as surface damage of precast concrete columns, displacement of tensioned wall bars, and long construction period, so as to eliminate appearance damage and avoid The effect of moving and speeding up construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

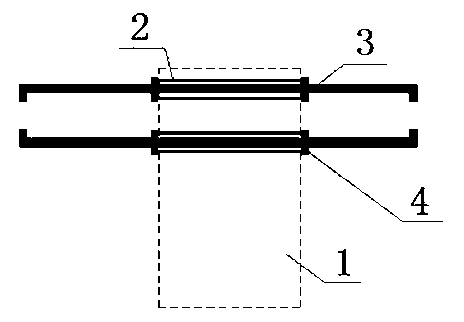

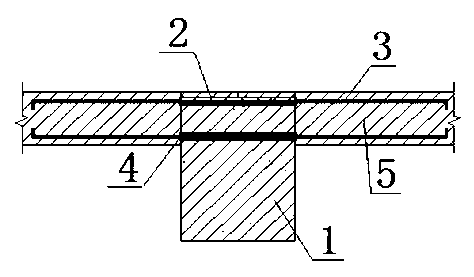

[0012] Embodiment of the present invention: the construction method of the wall reinforcement in the frame column: first, the casing 2 is pre-embedded when the frame column 1 is poured; Insert the wall reinforcement 3; finally, the wall reinforcement 3 is fixedly connected to the frame column 1.

[0013] The structure of the wall reinforcement in the frame column adopting the above method is as follows: figure 1 As shown, it includes the existing frame column 1, and the casing 2 is placed in the frame column 1 (the casing 2 is placed according to the actual construction requirements when the frame column 1 is poured). After the frame column 1 is poured and the formwork is removed, the pull The wall reinforcement 3 penetrates into the casing 2, and then the wall reinforcement 3 is fixedly connected to the frame column 1. In order to reduce the cost, the casing 2 can be a plastic pipe. For practicality and convenience, nuts can be installed on both sides of the wall reinforcem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com