Shear type expansion anchor rod and extension application thereof

A technology of expanding anchor rods and expansion plates, which is applied in the direction of installing anchor rods, sheet pile walls, pins, etc., can solve problems such as increased labor intensity, poor pull-out resistance, and damage to stable layers, and achieves simple and ingenious structure, convenient and reliable use , The effect of easy processing and manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

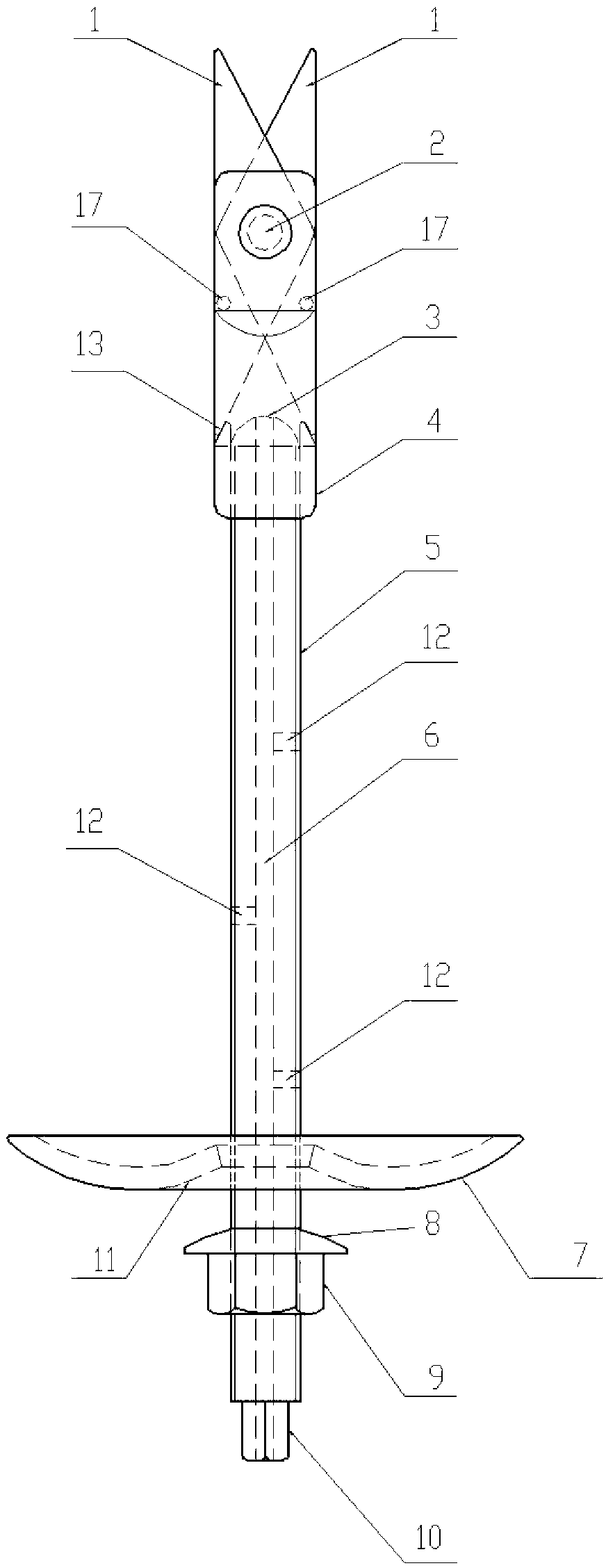

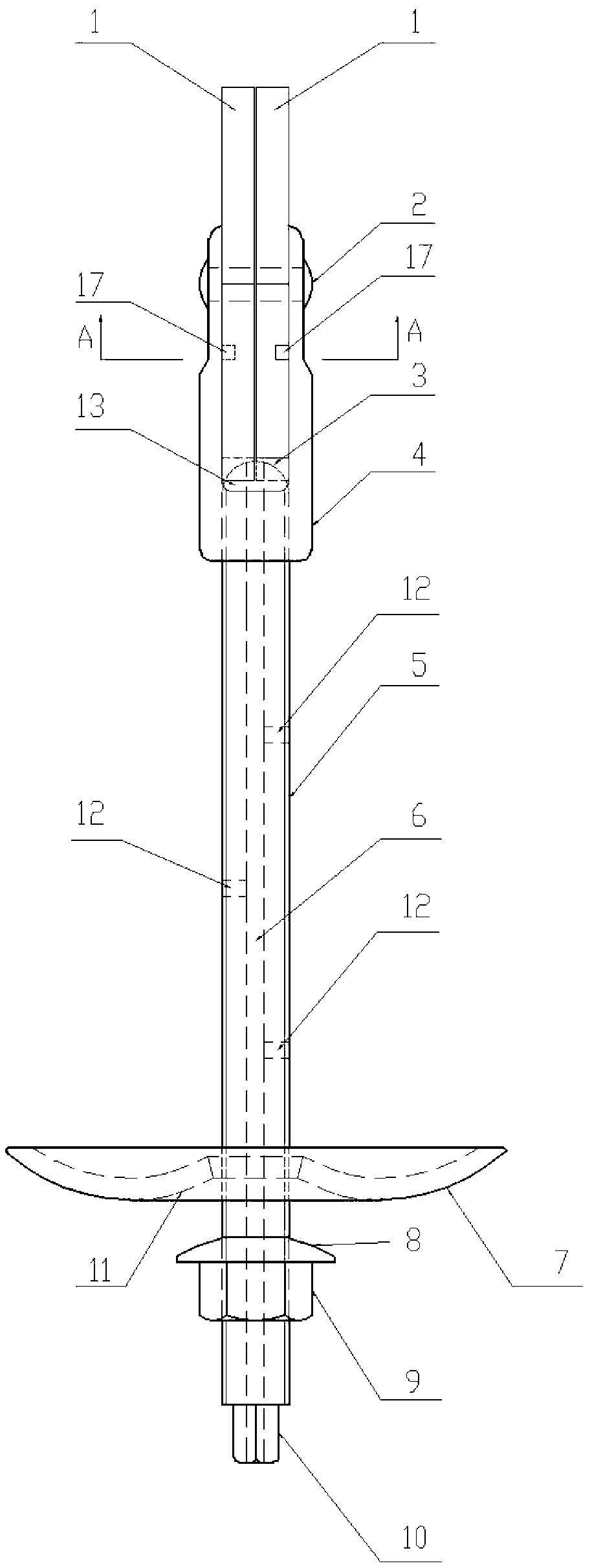

[0031] Below in conjunction with accompanying drawing and specific implementation for further description:

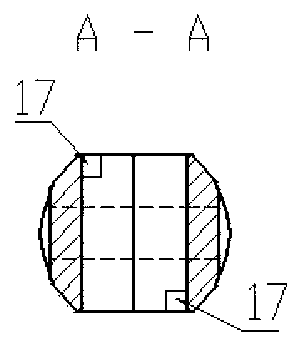

[0032] Referring to the accompanying drawings, the fixing part of the present invention is a lug nut support (4), and the lug nut support has two opposite support plates, and hinge holes are arranged on the upper part of the support plate; the expansion part is two An expansion plate (1), the two expansion plates are combined and embedded between the two support plates of the lug nut support, and are hinged with the support plate; the pusher is a screw rod matched with the lug nut support ( 5), the arc surface (3) at the top of the screw is in contact with the lower ends of the two expansion plates, and rotating the screw can directly push the two expansion plates outwards along the slope of the lower end of the expansion plate; of course , the threads on the screw can be full threads, or only threads are provided at both ends of the screw.

[0033] Limiting steps (13)...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com