Device and method capable of realizing precise regulation of rotary single-path optical fiber connector

A rotary connector and precision adjustment technology, applied in the coupling of optical waveguides, etc., can solve the problems of low production qualification rate, difficult optical path rotation alignment, high production difficulty, and achieve simple and easy assembly, device stability and indicators. Superiority, the effect of reducing the requirements for parts and machining accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the embodiments and with reference to the accompanying drawings.

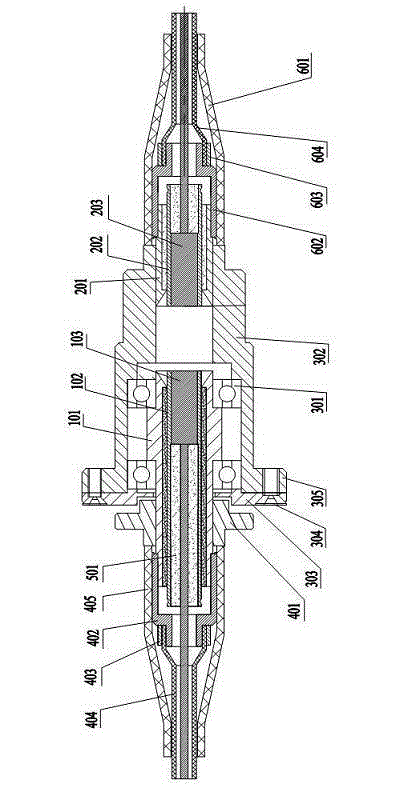

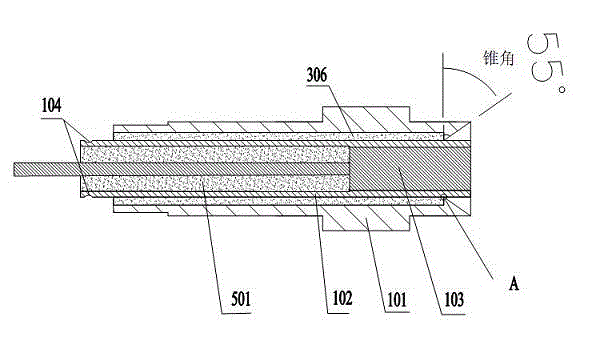

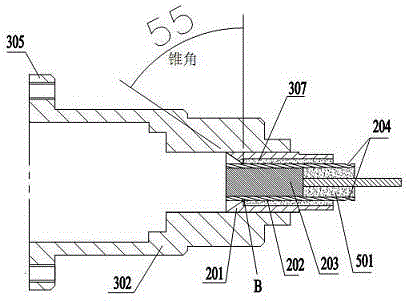

[0042] A precision adjustment device for realizing a single-way optical fiber rotary connector, including a connecting sleeve 302 and a bearing end cover 303, and the ring-shaped bearing end cover 303 is fixed on the outer edge of the left end of the connecting sleeve 302 with openings at both left and right ends by screws 304 On the piece 305, in the connecting sleeve 302, there is a large rotating angle adjustment cavity 306 at the left end and a small static angle adjustment cavity 307 at the right end, which are connected in turn in the rotating angle adjustment cavity 306 from the inside to the outside. The rotating optical fiber collimator 203, the rotating fixed sleeve 102, the rotating angle adjusting sleeve 101 and two precision bearings 301, the outer walls of the two precision bearings 301 and the inner wall of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com