Anchor cable breakage impact buffering and protecting device

An impact buffering and protection device technology, applied in the installation of bolts, construction, mining equipment, etc., can solve the problems of the anchor cable detaching from the drilling hole, low strength, weakening of the effect of the anchoring agent, etc. Simple, high load-carrying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] An embodiment of the present invention will be further described below in conjunction with accompanying drawing:

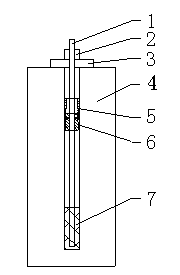

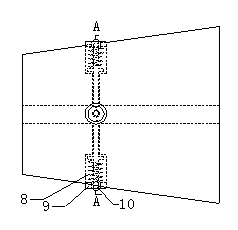

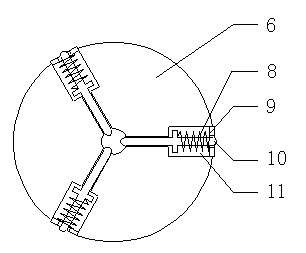

[0019] The anchor cable fracture impact buffer protection device of the present invention is mainly composed of a conical plug 6 and an open cylinder 5 which are sequentially set on the anchor cable 1; figure 2 and image 3 As shown, the conical plug 6 includes a conical cylinder with a central through hole, and three radial through holes that communicate with the central through hole are arranged at 120° on the outer wall of the conical cylinder, and the radial through holes There is a reserved hole 11 for expansion in the hole entry section, a preload pin 10 and a spring 8 set on the preload pin 10 are arranged in the radial through hole, and a package nut 9 is provided at the radial through hole; Figure 4 and Figure 5 As shown, the open cylinder 5 includes an inner tapered hole sleeve with a through groove 13 in the axial direction, and a plurality ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com