Window assembly installed on vehicle-mounted laser radar

A vehicle-mounted lidar and window technology, which is applied to vehicle components, transportation and packaging, transparent/reflective heating devices, etc. Avoid problems such as frost or fogging, and achieve high transmittance, increased cost, and high heating power density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

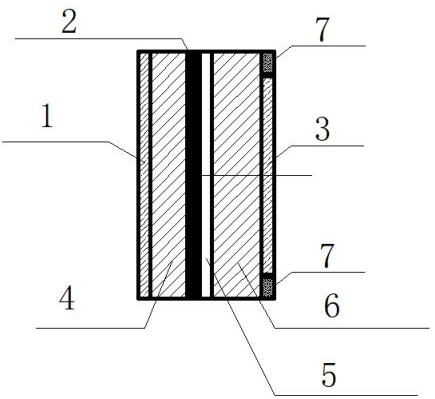

[0034] Embodiment one: if figure 1 As shown, a window assembly installed on a vehicle-mounted laser radar includes an outer sapphire substrate 4 and an inner H-K9L optical glass substrate 6, and a PVB polymer is arranged between the sapphire substrate 4 and the H-K9L optical glass substrate 6 The interlayer 5, the sapphire substrate 4 and the optical glass substrate 6 are bonded through the PVB polymer interlayer 5 to form a window assembly.

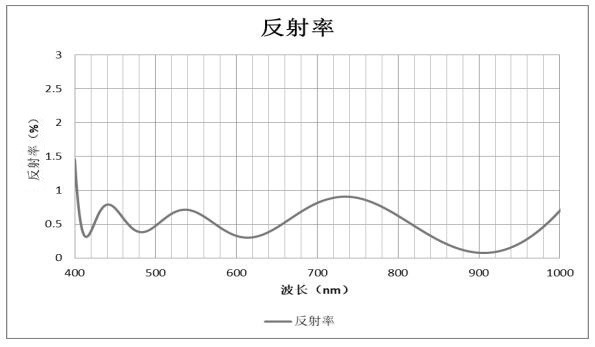

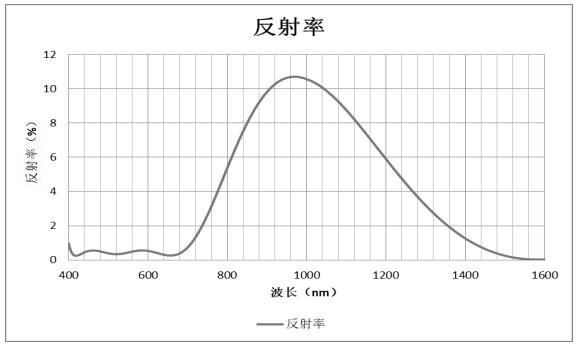

[0035] Specific to the sapphire substrate 4, the outer surface of the sapphire substrate 4 is coated with a waterproof anti-reflection film 1, which is used to reduce the reflection of visible light and at the same time to increase the reflection of the radar band (the radar working band is 905nm±30nm or 1550nm±30nm), and the spectral characteristics Such as figure 2 and image 3 As shown; the inner surface of the sapphire substrate 4 is coated with a black film 2. The function of this film is to ensure the consistency of the appearan...

Embodiment 2

[0044] Embodiment 2: Other structures are the same as Embodiment 1, the difference is that the heating defogging structure 7 is as Figure 11 As shown, the outer surface of the H-K9L optical glass substrate 6 is plated with an ITO conductive film 10, and on the ITO conductive film 10, the heating electrode strip 8 made of thick film paste and the electrode connected to the heating electrode strip 8 are coated. The terminal conductor 9 is a terminal conductor 9 used for connecting control systems such as an external power supply. The heating and defogging structure of this embodiment has a more uniform heating effect, but the overall transmittance is slightly lower than that of the heating and defogging structure of Embodiment 1, and the cost is somewhat increased.

[0045] Specifically, the heating electrode 8 in the above two embodiments is coated with thick film slurry, the width is 1mm~5mm, the total resistance is controlled at 10~200 ohms, the resistance range can also be in...

Embodiment 3

[0048] Embodiment three: other structures are the same as embodiment two, the difference is that the thickness of the sapphire substrate 4 is 0.5mm, the thickness of the H-K9L optical glass substrate 6 is 5.14mm, and the thickness of the polymer interlayer is 0.36mm. The total thickness of the window assembly is equal to 6 mm, and the cost per piece of the window assembly is 200 yuan.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com