Basket type extraction tank and basket thereof

A technology for extracting tanks and baskets, applied in the field of basket-type extraction tanks and their baskets, which can solve problems such as drifting, blockage of circulation pipelines, and floating baskets, so as to avoid position deviation, reduce space requirements, and increase penetration rate accelerated effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

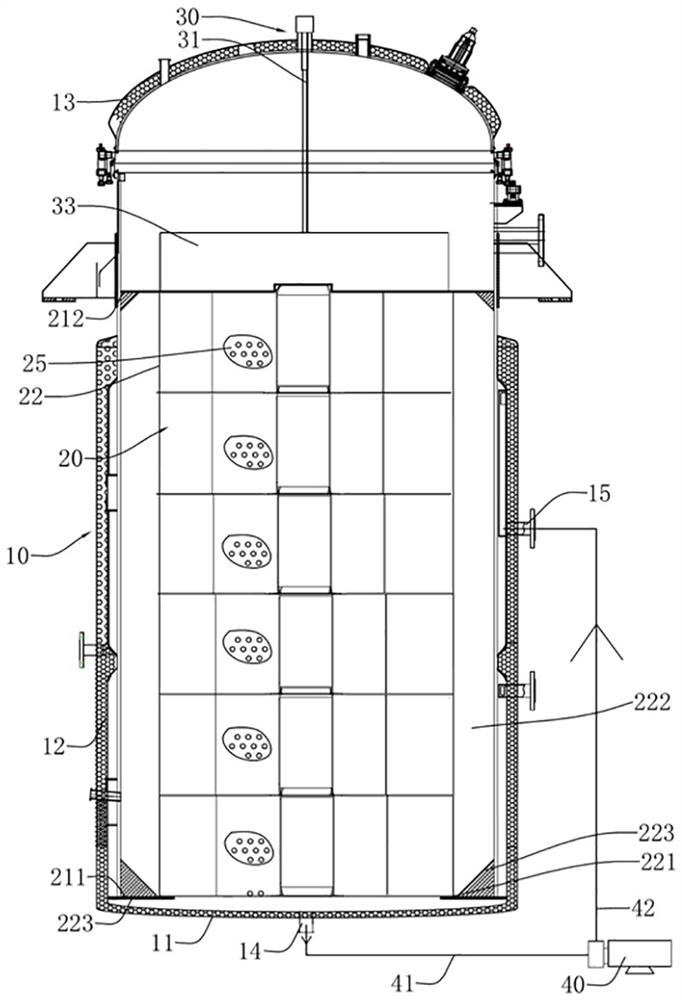

[0039] Such as figure 1 As shown, the basket extraction tank of this embodiment includes a tank body 10 , a basket 20 and a press fitting 30 . The fluid in the tank body 10 can be solvent or volatile oil. The tank body 10 has a bottom wall 11 , side walls 12 and a top cover 13 . The bottom wall 11 has an outlet 14, the side wall 12 has an inlet 15, and the top cover 13 is connected to the side wall 12 through a switch and a locking mechanism.

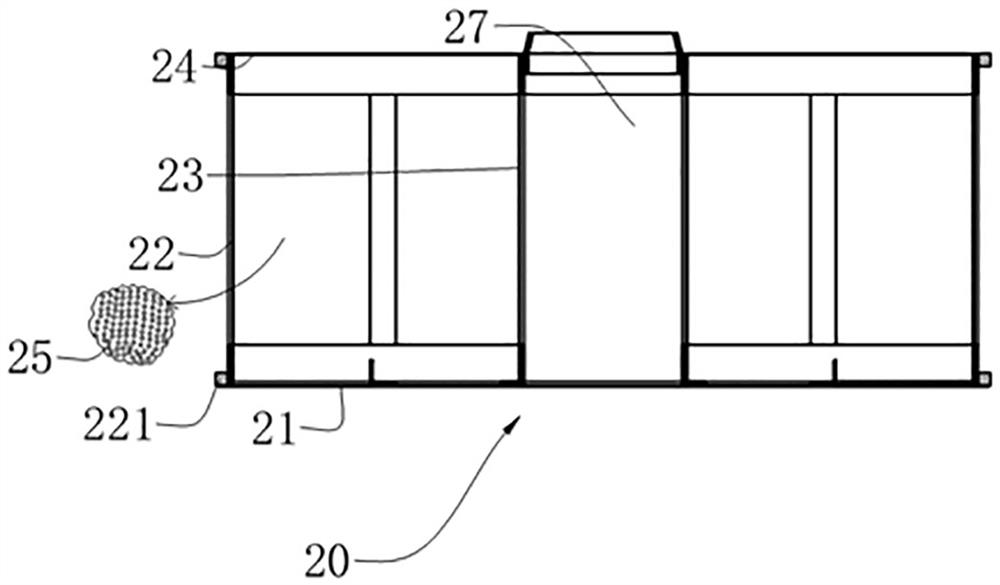

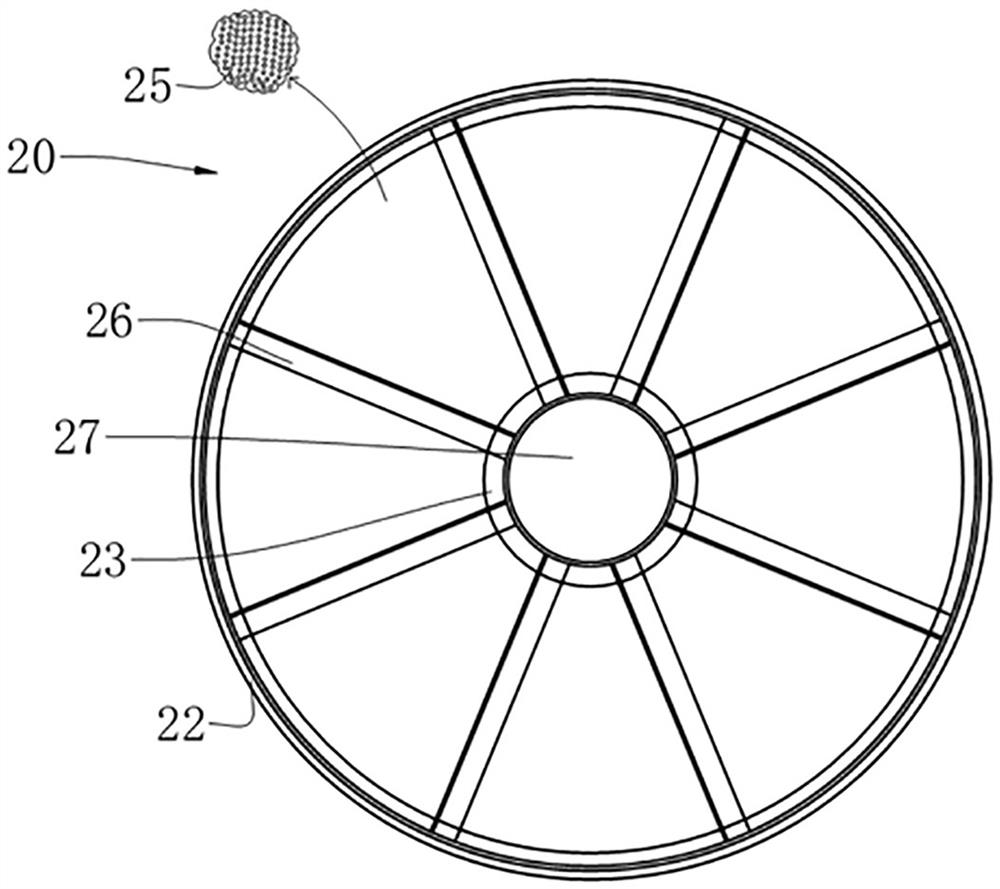

[0040] Such as Figure 2 to Figure 4 As shown, the basket 20 is disposed in the tank body 10 , and the basket 20 has a basket bottom 21 , an outer ring wall 22 , an inner ring wall 23 and a basket cover 24 . The bottom 21 of the basket, the outer ring wall 22 and the inner ring wall 23 all have mesh holes 25 (a partial enlarged view is shown in the figure). The inner ring wall 23 and the outer ring wall 22 are connected by a plurality of ribs 26, and the inner ring wall 23 forms Drain hole 27 through up and down. The basket cover 2...

no. 2 example

[0054] As a further preferred solution, the volume of the tank body 10 is 5L to 50 m 3 , the distance formed from the outer ring wall 22 to the side wall 12 is 7 mm to 9.9 mm; the ring thickness distance formed between the inner ring wall 23 and the outer ring wall 22 is less than or equal to 800 mm; the height of the basket 20 is less than or equal to 800 mm . The single mesh area of the mesh 25 of the basket 20 is 0.785 mm 2 to 7mm 2 , the opening ratio of the mesh is between 40% and 75%.

[0055] Compared with the mesh plate of the existing basket, the single mesh diameter is 7 mm 2 to 314mm 2 , The opening ratio on the stencil is 60% to 90%. The technical solution provided by the present invention increases the channel area for the solvent to enter the basket while ensuring that the material is not carried out with the solvent in a large amount in the basket. In addition, compared with the existing solution of 20-30 mm distance from the outer ring wall to the side w...

no. 3 example

[0060] As an alternative, see Figure 5 , the pressing part of this embodiment includes a pressing rod 51 and a pressing cover 33, and the difference from the first embodiment is that the pressing rod 51 extends in the horizontal direction, and the pressing rod 51 is driven by a motor 52 and can pass through Tank body, motor 52 is located outside the tank body. The press-fit rod 51 abuts against the top of the press-fit cover 33 to limit the displacement of the press-fit cover 33 .

[0061] Examples of baskets for basket extraction:

[0062] The basket 20 that is used for basket extraction of the present embodiment, basket 20 has basket bottom 21, outer ring wall 22, inner ring wall 23 and basket cover 24, basket bottom 21, outer ring wall 22, inner ring The walls 23 all have mesh holes 25, the inner ring wall 23 and the outer ring wall 22 are connected by reinforcing ribs 26, and the inner ring wall 23 forms a drainage hole 27 through up and down; the basket cover 24 has a ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Mesh area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com