Water storage tank and water storage type water heater applying the same

A water storage tank and water tank technology, which is applied to fluid heaters, lighting and heating equipment, etc., can solve the problems of inability to flexibly adjust the hot water capacity of the water tank, low hot water utilization rate, and no capacity expansion function, etc. The effect of reducing heat energy waste and saving materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

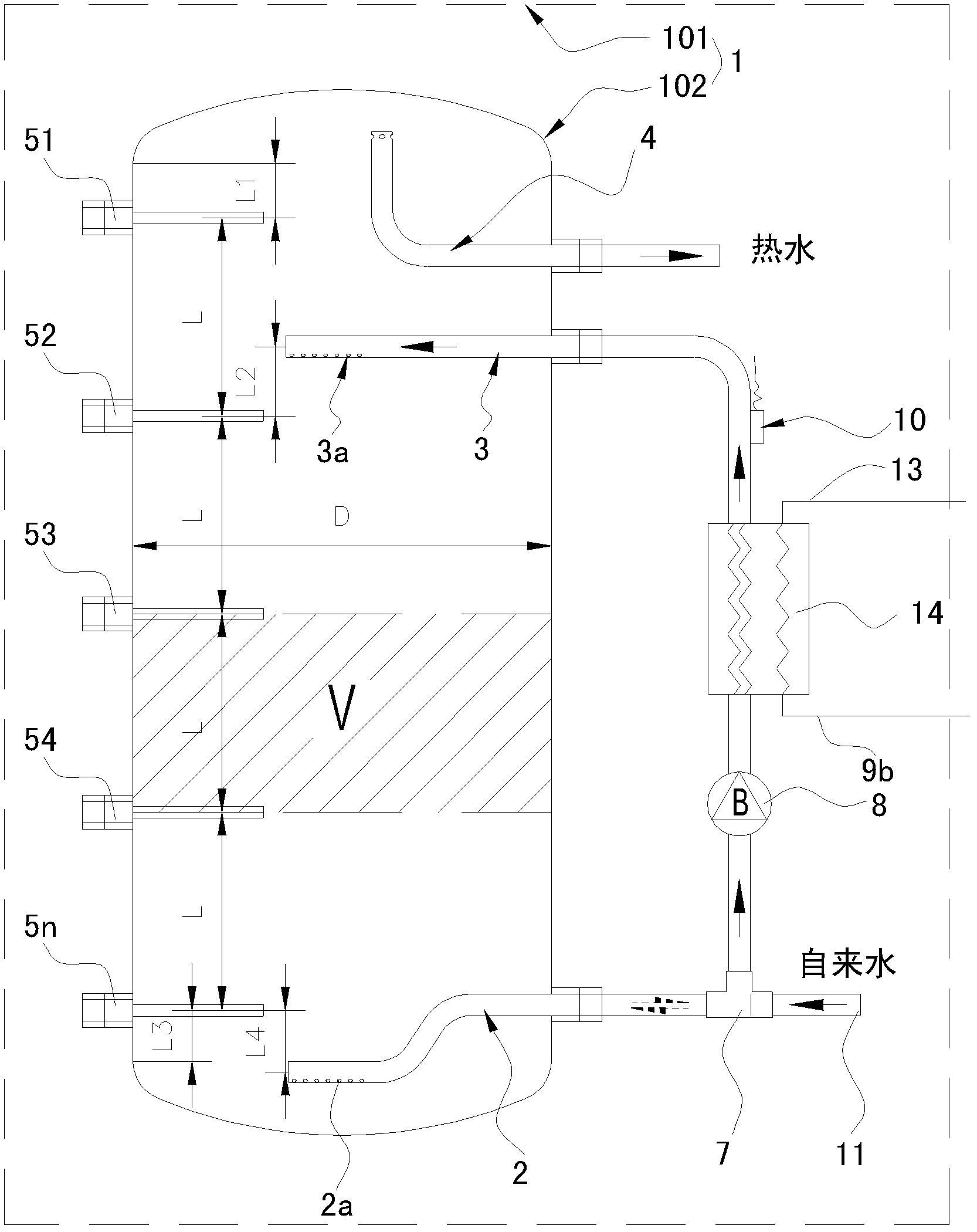

[0030] See figure 1 , the water storage tank 1 is mainly composed of a water tank shell 101, a water tank liner 102, a circulating water inlet pipe 3, a circulating water outlet pipe 2, a cold water inlet pipe 11, a hot water outlet pipe 4, a frequency conversion water pump 8 and a heat exchanger 9. The tank 102 is in the shape of a cylinder. A circulating water inlet pipe 3 and a hot water outlet pipe 4 are arranged on the upper part of the water tank inner tank 102. Five temperature sensing packages (ie temperature sensors) 51 , 52 , 53 , 54 , 5n for detecting the temperature at different positions in the water tank liner 102 are provided, and the temperature sensing packages are inserted into the water tank liner 102 .

[0031] In order to accurately detect the outlet water temperature of the water tank liner 102, the position of the temperature sensing package 51 with the highest height should be located on the top of the water tank liner 102 as much as possible. In order...

Embodiment 2

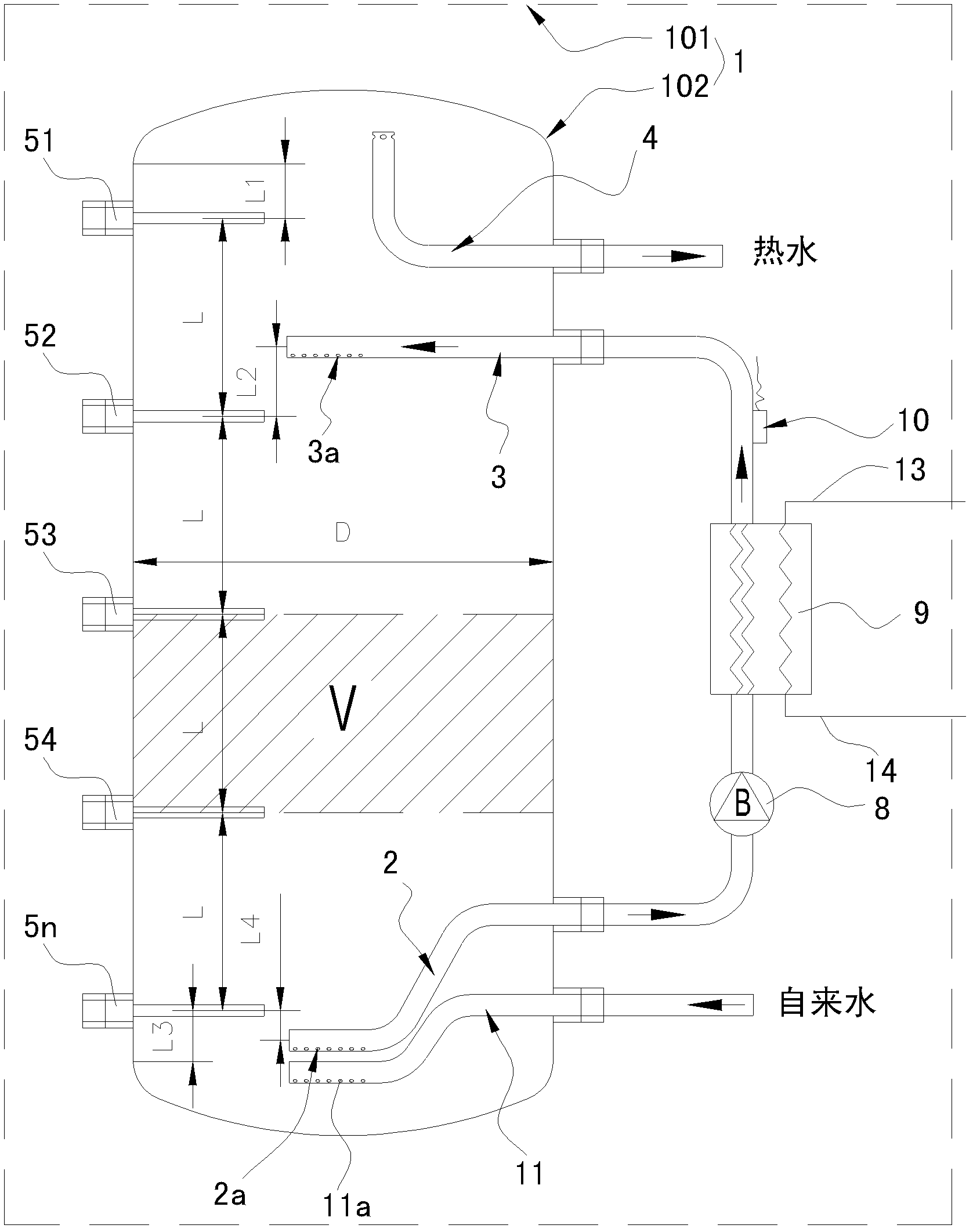

[0046] See image 3 , and the difference from Embodiment 1 is that the temperature sensing package is attached to the outer wall of the water tank liner 102, and the water inlet of the water pump 8 is directly connected to the second end of the circulating water outlet pipe 2. The cold water inlet pipe 1111 is arranged on the water tank liner 102 below the circulating water outlet pipe 2. The first end of the cold water inlet pipe 1111 extends into the water tank liner 102, and the mouth of the first end is closed. The lower part of the pipe wall is provided with a through hole 11a. In the water storage tank of this embodiment, the cold water inlet pipe 11 and the circulating water outlet pipe 2 are arranged separately, so that the cold water supply and the direct heating of the water at the bottom of the water tank can be sent to the top of the water tank at the same time, which better reflects the capacity increase effect.

Embodiment 3

[0048] See Figure 4 , different from Embodiment 2, this embodiment has two water tank liners 102a, 102b, and the two water tank liners 102a, 102b are connected in series through the connecting pipe 6 from front to back according to the water flow direction, and the first connecting pipe 6 One end stretches into the bottom of the previous water tank liner 102a, and its second end stretches into the top of the rear water tank liner 102b. The circulating water inlet pipe 3 and the hot water outlet pipe 4 are arranged on the top of the front water tank liner 102a. The water outlet pipe 2 is located at the bottom of the last water tank liner 102b, and the water tank liner 102 is also provided with 4 temperature sensors 51, 52, 53, 54 for detecting the temperatures at different positions in the water tank liner 102 respectively.

[0049] The water storage tank 1 adopting a plurality of water tank liners 102 in series has the following benefits: (1) the mode of connecting a pluralit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com