Series resonance voltage-withstanding partial-discharge test method utilizing frequency modulation phase shift

A technology of series resonance withstand voltage and test method, which is applied in the direction of testing dielectric strength, etc., and can solve the problems of large volume, low efficiency, high noise, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

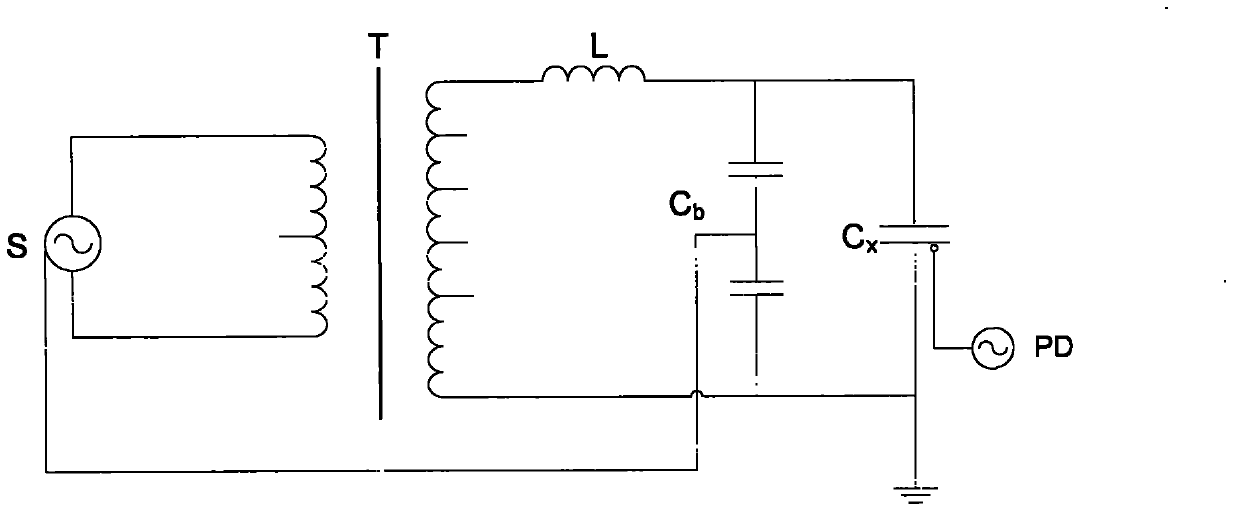

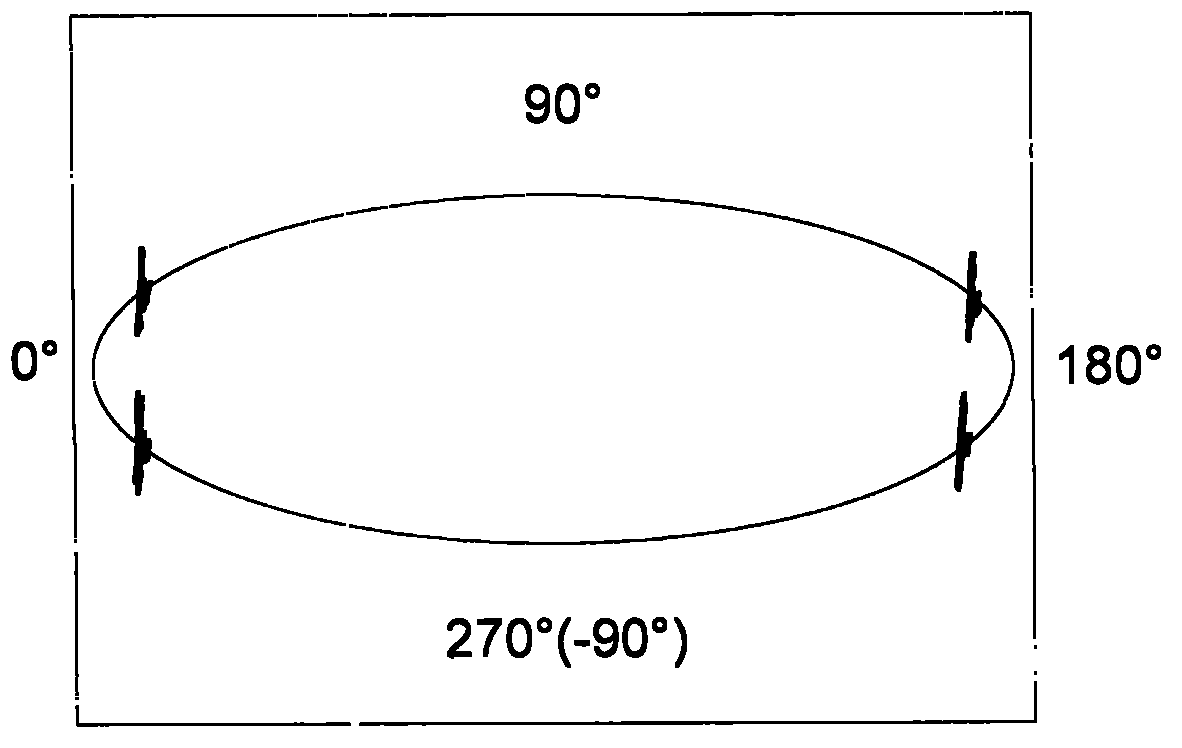

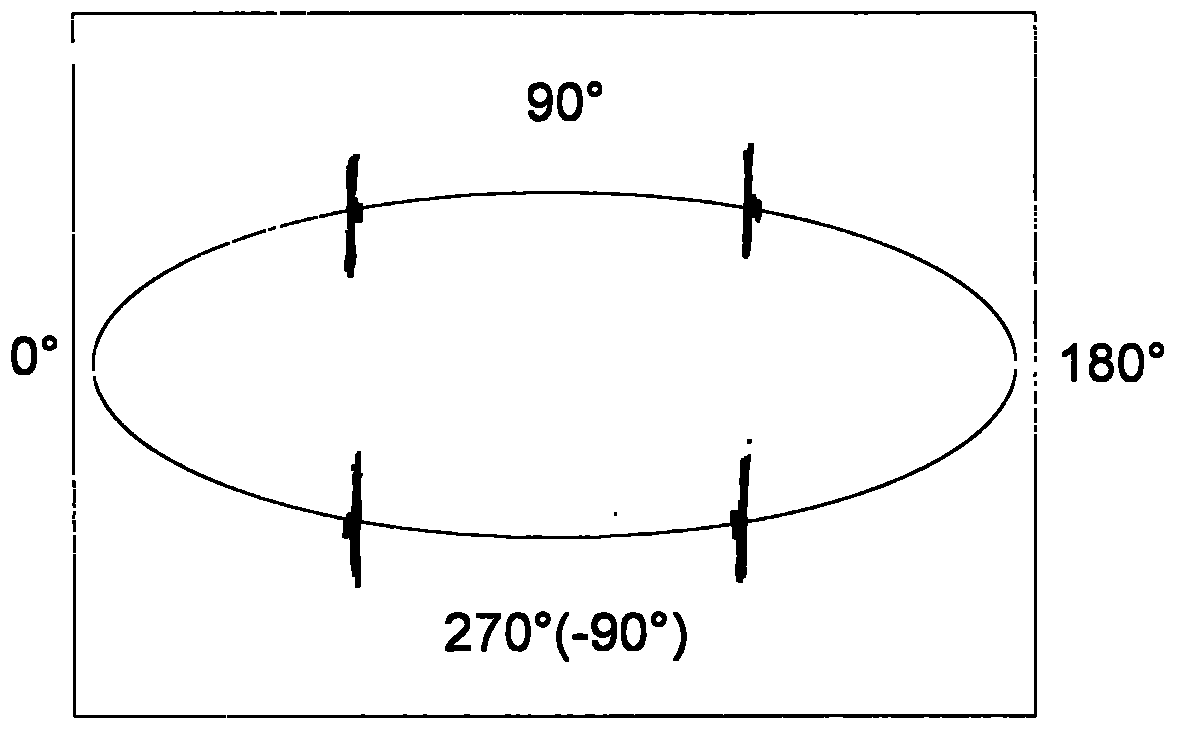

[0006] Example 1 see attached figure 1 As shown in the frequency-modulated series resonant partial discharge test system using a rectangular wave variable frequency power supply, this method is used as follows: first use a small pulse width (such as 2%) to excite the frequency sweep tuning to make the system reach a resonance state, and then increase the pulse width Boost. With the increase of the pulse width, the turn-on and turn-off of the variable frequency power switch tube will form 4 glitches on the time base of the amplifier (see attached figure 2 ) will move closer to ±90° (see attached image 3 ). If the final resonant voltage reaches the set value of the test voltage, the 4 burrs close together and become 2 at ±90° (see attached Figure 4 ), you can operate the partial discharge instrument to read the partial discharge amount of the test product by opening the window in the first and third quadrants; if the burr is not close to the resonance voltage and has reach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com