Viscosity-controlled processing of liquid food

A liquid food, viscosity technology, applied in the direction of viscosity control, food preservation, adaptive control, etc., can solve the problems of low shear rate and undetermined viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

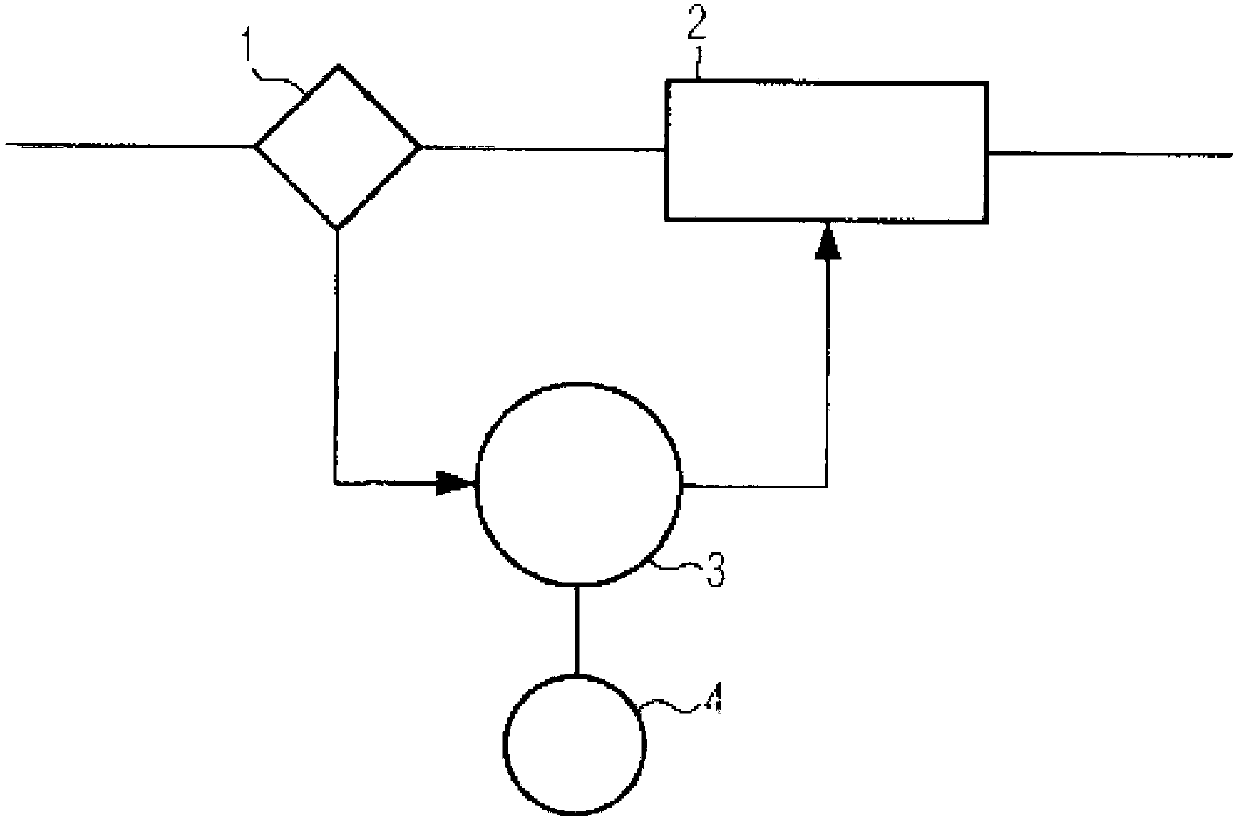

[0042] figure 1 A production line is shown with a measuring device 1 for measuring the viscosity of liquid food products, a working device 2 for processing liquid food products, and on the one hand based on the measured viscosity values and on the other hand based on stored data in a memory 4 Control device 3 for controlling the working device. In the example shown, the liquid food may be fruit juice, and the working device 2 may be a flash pasteurizer or an ultra high temperature (UHT) pasteurizer for fruit juice pasteurization. In the following, it will be further assumed that the working device 2 is a flash pasteurizer (FP) for heating fruit juice. Of course, the invention is not limited to working equipment 2 or liquid food products in this particular way.

[0043] The size of FP mainly depends on the viscosity of the liquid food to be processed. When it is supplied to the customer, the FP, can be a plate heat exchanger or a tube heat exchanger sized for a typical app...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com