Supercritical Water Cooled Reactor Fuel Assembly

A fuel assembly and water-cooled reactor technology, which is applied in the direction of reactor fuel elements, reactors, and greenhouse gas reduction, can solve the problems of complex structure, inapplicability, and differences in structural forms of the throttling parts of boiling water reactors, so as to improve neutron economy, Uniform moderation, favorable for installation and replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

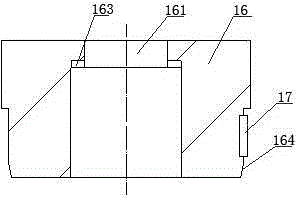

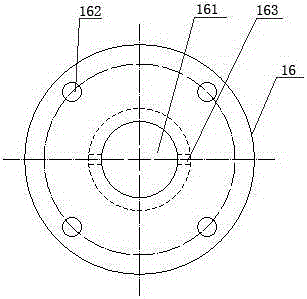

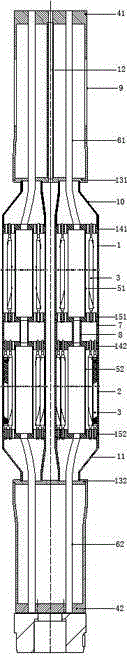

[0044] Such as figure 1 and figure 2 As shown, the supercritical water-cooled reactor flow regulating structure includes a distribution cylinder 16, and the upper end surface of the distribution cylinder 16 is provided with a main flow hole 161 and a plurality of auxiliary flow holes 162, and the auxiliary flow holes 162 are evenly distributed around the main flow hole 161. The cooling water enters the fuel assembly through the main distribution hole 161 , and the moderator enters the fuel assembly through the auxiliary distribution hole 162 to realize the distribution of the cooling water and the moderator. Wherein, the number of auxiliary flow holes 162 can be freely set according to the number of moderator tubes in the fuel assembly. The diameters of the main flow hole 161 and the secondary flow hole 162 can be set according to the working state of the fuel assembly. By replacing the invention with different apertures, the adjustment and distribution of cooling water and...

Embodiment 2

[0046] Such as figure 1 and figure 2 As shown, in this embodiment, on the basis of Embodiment 1, the main distribution hole 161 is designed as a stepped hole with a thin top and a thick bottom, and the step surface of the main distribution hole 161 is provided with a positioning groove 163 . The positioning slot 163 is used for remote operation. By inserting the long rod into the positioning slot 163, the present invention can be installed, disassembled or adjusted remotely, making the present invention more usable. Especially when the temperature is high, it is safe to prevent personnel from installing, disassembling or adjusting the present invention at close range.

Embodiment 3

[0048] Such as figure 1 and figure 2 As shown, on the basis of Embodiment 1, this embodiment also includes a positioning key 17, the diameter of the upper end of the distribution cylinder 16 is larger than the diameter of the lower end of the distribution cylinder 16, and the positioning key 17 is arranged on the outer circle of the lower end of the distribution cylinder face. The present invention is installed in the water hole of the lower plate of the core, and a stepped surface is obtained by changing the diameter of the distribution cylinder 16. The stepped surface can facilitate the installation of the present invention, improve the positioning accuracy, and realize the axial compression of the present invention. The positioning key is used to limit the circumferential rotation of the present invention.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com