Fiber-reinforced plastic molded article, manufacturing method thereof, and elevator

A technology of reinforced plastics and manufacturing methods, applied to elevators in buildings, building structures, building components, etc., to achieve high sound-absorbing characteristics, high rigidity, sound-absorbing and sound-insulating properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

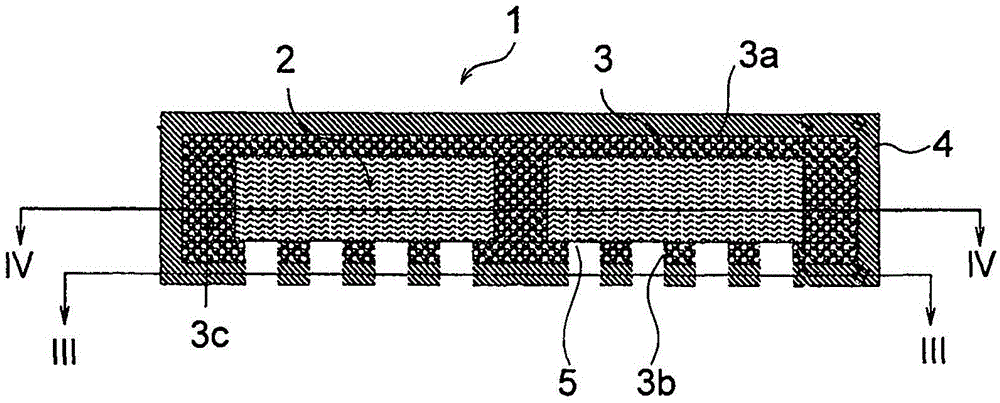

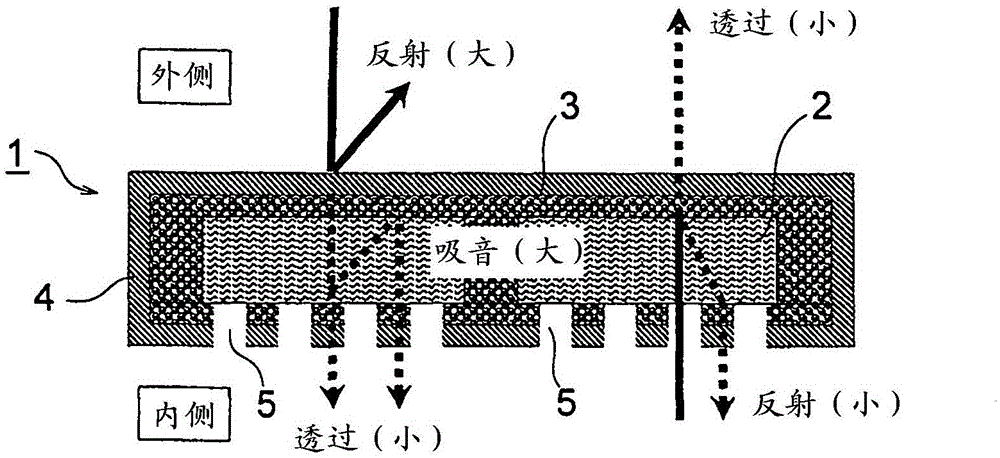

[0055] figure 1 It is a cross-sectional view showing a fiber-reinforced plastic molded article 1 (hereinafter referred to as an FRP molded article) according to Embodiment 1 of the present invention.

[0056] This FRP molded article 1 has: an open cell body 2; a hard closed cell body 3 covering the open cell body 2; a fiber reinforced plastic (hereinafter Abbreviated as FRP) 4. A resin is impregnated and cured in this FRP4.

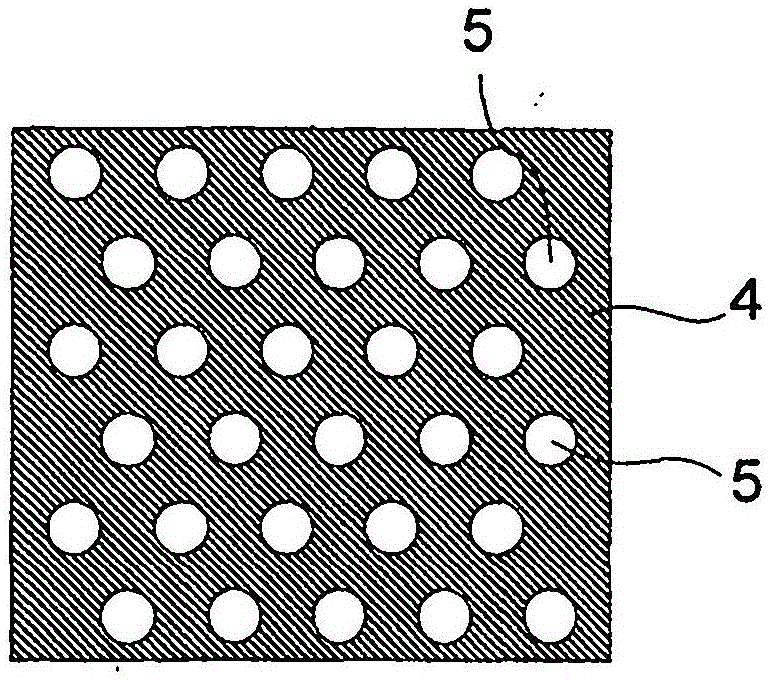

[0057] Formed on the lower surface of the FRP molded body 1 are a plurality of image 3 The openings 5 are arranged as shown, and the interconnected cell 2 communicates with the outside through the openings 5 .

[0058] Hard independent cells 3 by Figure 5 The shown upper flat plate portion 3a as the first flat portion, the lower flat plate portion 3b as the second flat portion, and Figure 4 As shown, the open-cell body 2 is formed by the supporting part 3c of the divided part 2a divided into quadrilaterals.

[0059] Here, the FRP4 that is the...

Embodiment approach 2

[0085] Figure 9 It is a cross-sectional view showing an FRP molded body 1A according to Embodiment 2 of the present invention.

[0086] In the present embodiment, in the FRP molded body 1A, in the hard closed cell body 3A, the open cell body 2 is divided into triangular divided portions 2 a by the support portion 3Ac.

[0087] Other structures are the same as those in Embodiment 1.

[0088] The FRP molded body 1A of the present embodiment has higher rigidity than the FRP molded body 1 when the area of the hard closed cell body 3A is the same as that of the hard closed cell body 3 of the first embodiment.

[0089] Other functions and effects are the same as those of the FRP molded article 1 of the first embodiment.

Embodiment approach 3

[0091] Figure 10 It is a cross-sectional view showing an FRP molded body 1B according to Embodiment 3 of the present invention. In this embodiment, an aluminum metal film 20 is pasted on the upper surface and the lower surface of FRP 4 using an adhesive material 21 .

[0092] Other structures are the same as those in Embodiment 1.

[0093] Since the metal thin film 20 is pasted on the upper surface and the lower surface of the FRP molded body 1B of this embodiment, compared with Embodiment 1, rigidity and flame retardancy can be further improved as a sandwich structure.

[0094] In addition, the metal thin film 20 may be pasted on only one surface.

[0095] Other functions and effects are the same as those of the FRP molded article 1 of the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com