Submerged plant underwater turf cultivation structure and submerged plant underwater turf planting method

A technology for underwater turf and submerged plants, applied in the fields of botanical equipment and methods, horticulture, and application, can solve the problems of large consumption of manpower and material resources, secondary pollution of the underwater environment, and large amount of restoration works, so as to reduce labor The effect of strength, reduction of working time in water, and convenient transportation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The submerged plant underwater turf culture structure and planting method of the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

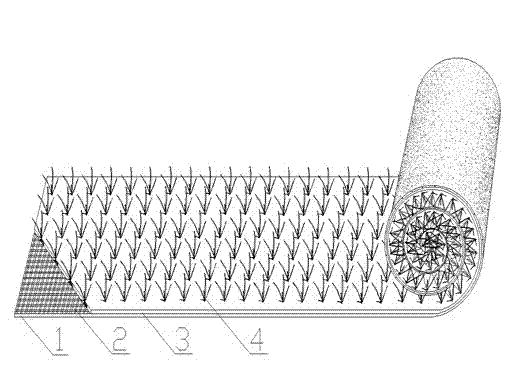

[0020] As shown in the figure, the underwater turf cultivation structure of submerged plants of the present invention comprises a lower clay layer 1 laid in a flat hard seedling pool or tank on the bottom surface, and the top of the lower clay layer 1 is laid with degradable natural materials. The seedling raising grid 2 formed; the seedling raising grid 2 is laid with an upper clay layer 3, and the seedling raising grid 2 and the upper clay layer 3 stick together to form a seedling raising matrix, and the submerged plants 5 are positioned on the seedling raising matrix, wherein the lower clay layer 1 and The thickness of the upper clay layer 3 is about 1 cm.

[0021] In the method for planting submerged plants underwater turf of the present invention, the se...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com