Pouring gate flow control device for preventing rotational flow from generating in continuous casting tundish

A continuous casting tundish and tundish technology, which is applied to casting equipment, casting molten material containers, metal processing equipment, etc., can solve problems affecting the quality of molten steel, improve yield, improve cleanliness, and prevent swirling the formation of the effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

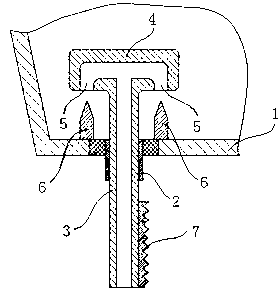

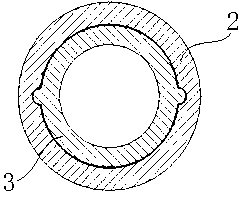

[0026] combine figure 1 and figure 2 , a nozzle flow control device for preventing swirling flow in a continuous casting tundish according to this embodiment, comprising a casing 2, a liquid discharge pipe 3, a liquid inlet plate 4, a flow guide hole 5, a flow control plug rod 6 and a lifting mechanism, The drain pipe 3 extends into the tundish through the bottom 1 of the tundish, and the drain pipe 3 is hollow inside. In this embodiment, a sleeve 2 is provided at the contact between the drain pipe 3 and the bottom 1 of the tundish. The casing 2 is sleeved on the outside of the discharge pipe 3, and there is an annular gap between the casing 2 and the discharge pipe 3. The above-mentioned annular gap is connected with the inert gas input device, and the inert gas is blown through the bottom. The gas method can effectively prevent the molten steel from absorbing gas. One end of the liquid discharge pipe 3 protruding into the tundish is fixedly connected with a liquid inlet ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com