Motor wheel set unit of motor rigid shaft-holding gearless driving

A technology without gears and motor wheels, which is applied in the direction of transmission devices driven by electric motors, can solve problems such as increasing structural costs and life-cycle maintenance cycle costs, affecting the performance of moving train curves, and increasing the wheelbase of bogies, etc., to achieve increased The cost of the whole life maintenance cycle, the effect of reducing the cost of the whole life maintenance cycle and increasing the noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach

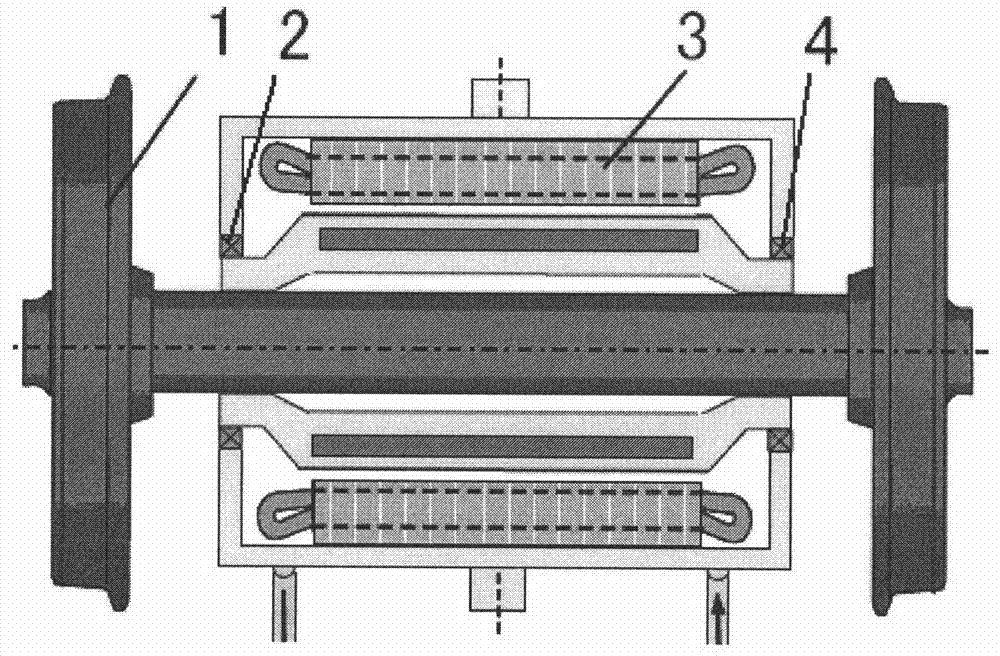

[0010] The specific implementation method is: make the motor center line coincide with the axle center line of the wheel pair 1, the axle is the motor rotor, the motor casing is the motor stator 3, and the motor stator passes through two bearings of part numbers 2 and 4 (i.e. bearing one and bearing 2) Directly rigidly supported on the axle; without gear transmission, the electromagnetic torque generated by the motor directly drives the axle, and the counter moment generated by the motor casing is balanced by the motor pull rod on the casing, and the rubber joints at both ends of the motor pull rod are respectively connected to the motor The shells are connected to the frame beams.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com