Rotor type compressor suitable for high-speed rotation

A high-speed rotating, rotor-type technology, used in rotary piston/oscillating piston pump combinations for elastic fluids, rotary piston/oscillating piston pump components, components of pumping devices for elastic fluids, etc. , can solve the problem that the capacity improvement is not enough to achieve low-temperature heating, and achieve the effect of solving the lack of heating capacity, improving product capacity, and improving the ratio of cold to weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] Below in conjunction with accompanying drawing and embodiment the present invention will be further described:

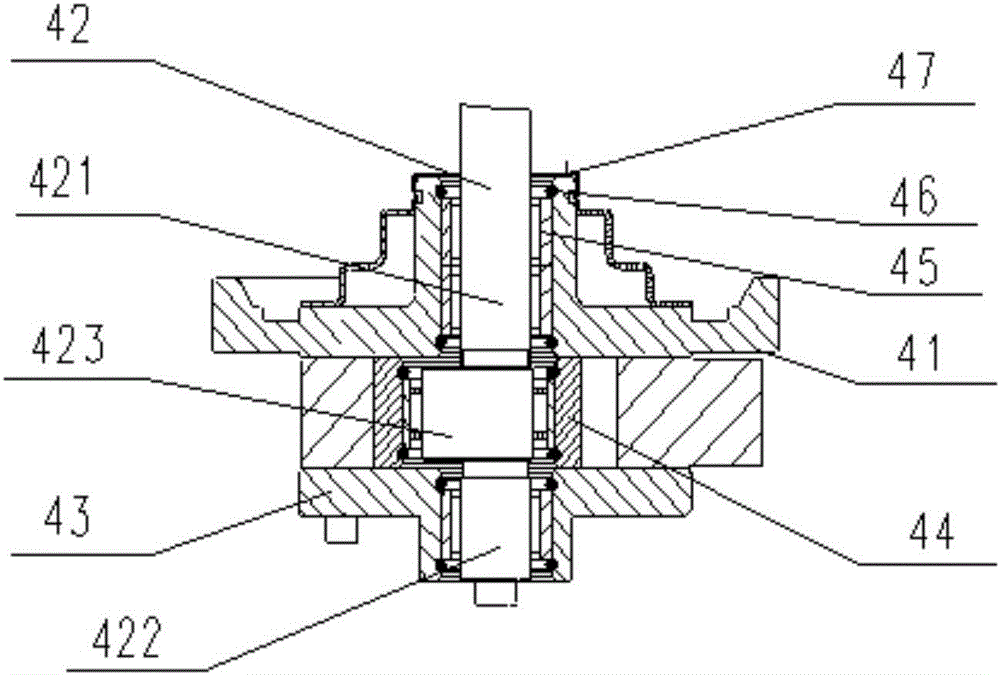

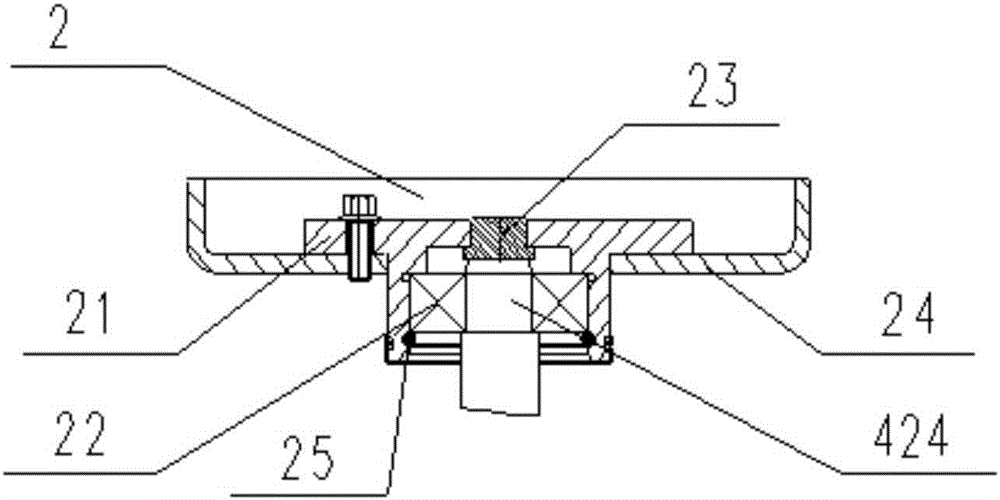

[0022] For high-speed applications, such as the operating frequency above 200Hz and the speed of 12000rpm, the original sliding friction structure of the rotary refrigeration compressor cannot adapt, and the sliding friction structure must be changed to a rolling friction structure to achieve high speed. speed requirements. The present invention adopts a rolling friction kinematic pair structure, which solves the difficulty that the sliding friction kinematic pair of the rotor-type refrigeration compressor cannot handle under high-speed conditions, and achieves the goal that the rotor-type refrigeration compressor can be applied to refrigeration applications with a rotation speed above 12000rpm purpose, as follows:

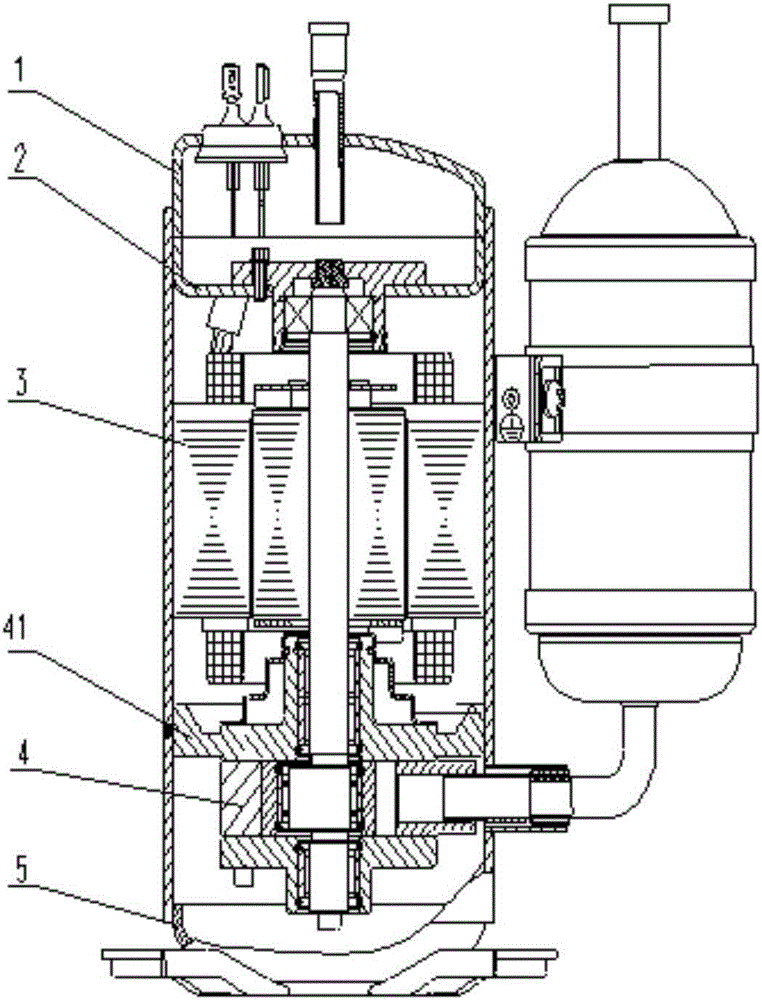

[0023] see figure 1 The rotary compressor suitable for high-speed rotation of the present invention includes an upper housing assembly 1 , an ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com