Pressing type beverage bottle

A beverage bottle and pressing technology, applied in the field of beverage bottles, can solve the problems of increasing assembly process, increasing material cost and processing cost, and many parts and components, and achieves the effect of reducing processing cost, reducing raw material cost and small operation range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

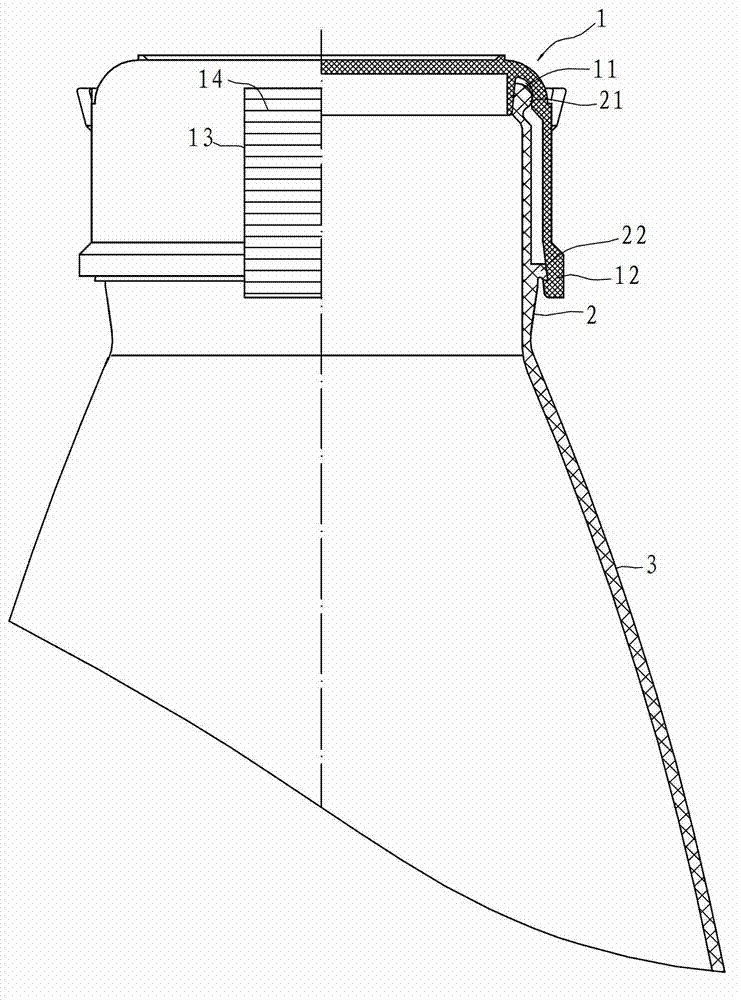

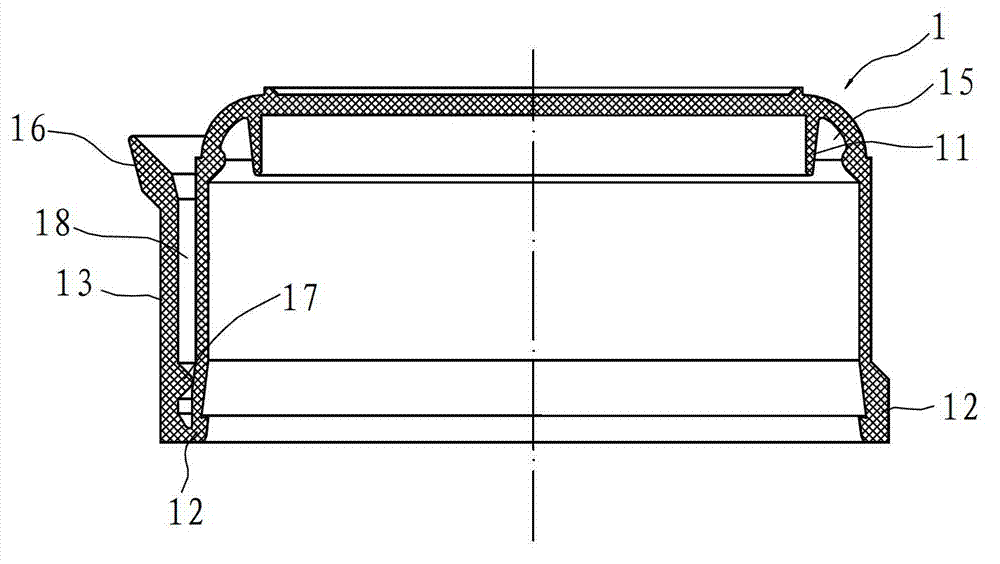

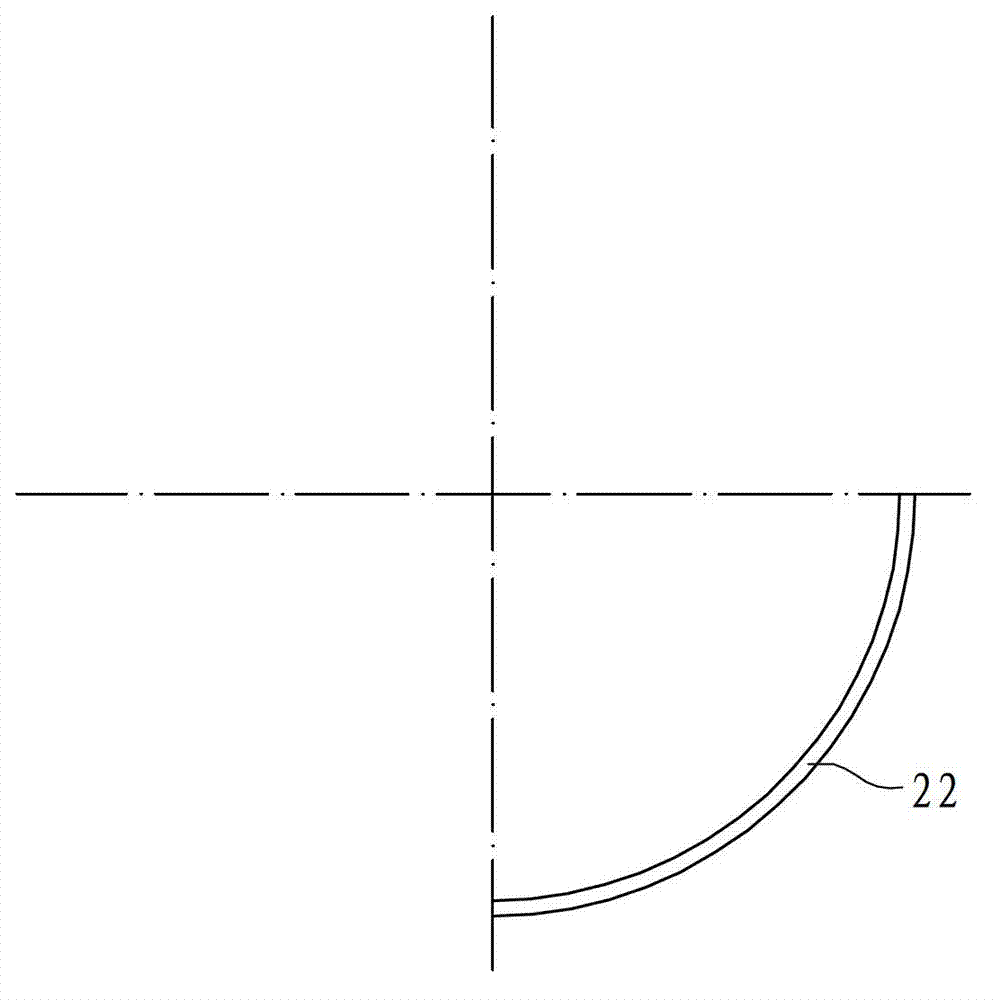

[0027] Example 1, such as figure 1 and figure 2 As shown, the push-type beverage bottle in this embodiment includes a bottle body 3 and a bottle cap 1, the bottle body 3 has a bottleneck 2, the bottleneck 2 is formed with a bottleneck, and the outer wall of the lower end of the bottleneck 2 protrudes with an engaging portion 22 , the engaging portion 22 is annular (see image 3 As shown), the bottle cap 1 is arranged on the bottle neck 2 and covers the bottle mouth. The outer wall of the bottle cap 1 is provided with a pressing block 13, and there are three pressing blocks 13 arranged evenly around the bottle cap peripheral wall (see Figure 4 shown). A force application portion 16 extends radially outward from the upper end of the pressing block 13 , and a horizontal non-slip pattern 14 is formed on the outer periphery of the pressing block 13 .

[0028] The inner lower end of the bottle cap 1 has claws 12 snap-fitted with the engaging portion 22, the outer wall of the up...

Embodiment 2

[0032] Example 2, such as Figure 7 As shown, the engaging portion 22 in this embodiment is multi-segmented, arranged at intervals in the circumferential direction, and the outer surface of each segment is arc-shaped. like Figure 5 and Image 6 As shown, the middle part of the bottle neck 2 has an external thread 20, and correspondingly, the inner middle part of the bottle cap 1 has an internal thread 10 adapted to the external thread 20, and the protective lines 14 are staggered and reticulated. Four pressing blocks 13 are evenly arranged around the bottle cap 1 peripheral wall (see Figure 8 shown). Refer to Example 1 for other structures.

[0033] When the pressing block 13 is pressed inward along the radial direction of the bottle cap 1, the claws 12 will tilt outward along the radial direction of the bottle cap and can disengage from the engaging part 22, and then apply a rotational movement to easily open the bottle cap. .

Embodiment 3

[0034] Example 3, such as Figure 9 and Figure 10 As shown, the protective lines 14 in this embodiment are wavy, and the middle part of the inner side wall of the pressing block 13 is not provided with a supporting part, as shown in Figure 10 As shown, refer to Example 2 for other structures.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com