Modifying and flooding agent for reutilization of residual polymers in formation and application thereof

A technology of polymer and flood control agent, applied in drilling compositions, chemical instruments and methods, etc., can solve problems such as adverse effects of stable production in oil fields, large space occupation, long swelling stage, etc., and reduce the concentration of produced polymers. , the effect of enhancing crude oil recovery and improving development effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1: Composition of Formation Residual Polymer Reuse Regulator and Displacement Agent

[0040] Formation residual polymer reuse control and flooding agent, based on 100% of the total control and flooding agent, is composed of 0.8% to 2.0% of water medium-dispersed polyacrylamide and the rest of formation water;

[0041] The water-medium-dispersed polyacrylamide is selected from water-in-water cationic emulsion WF40 (Beijing Demei Hi-Tech Co., Ltd.), with a solid content of 46.3% to 48.2%, an effective content of 18% to 20%, and a relative molecular mass of 750×10 4 ~800×10 4 , cationic degree is 38-41.

[0042] The formation water contains Na + , Ca 2+ , Mg 2+ , SO 4 2– 、HCO 3 – and Cl – of deionized water, where the Na + The concentration is 950.89mg·L -1 , Ca 2+ +Mg 2+ The concentration is 30.61mg·L -1 , CO 3 2- The concentration is 107.14mg·L -1 , SO 4 2– The concentration is 43.62mg·L -1 , HCO 3 – The concentration is 924.45mg·L -1 , Cl...

Embodiment 2

[0044] Embodiment 2, the solubility property of water-in-water cationic emulsion WF40

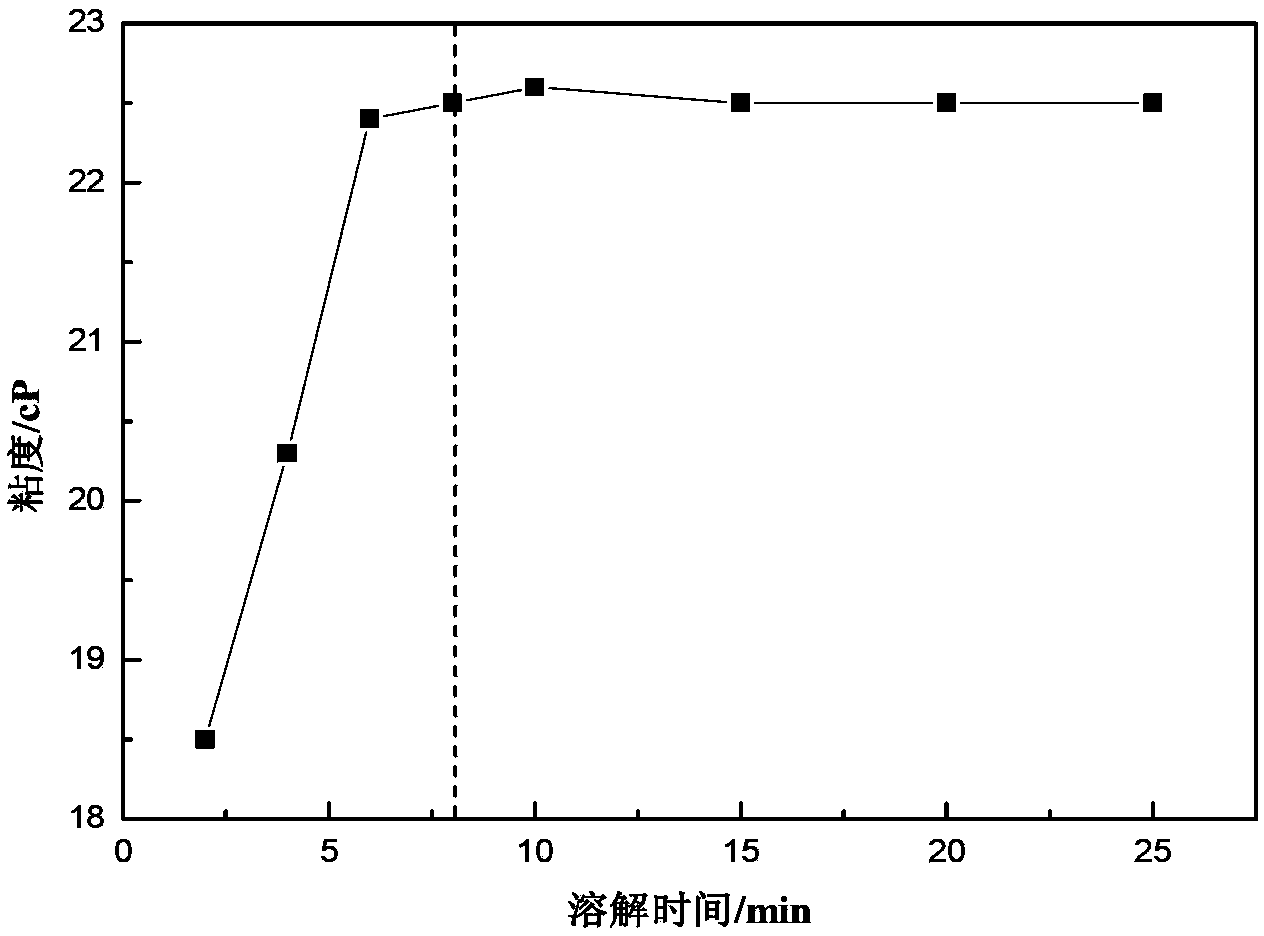

[0045] Weigh 1.5 g of the water-in-water cationic emulsion WF40 described in Example 1 and add it to 98.5 g of the formation injection water described in Example 1 to prepare a reuse control and flooding agent solution with a mass concentration of 1.5%. Stir at a constant speed of 400r / min, sample every 2min, at 20°C and 7.34s -1 Under certain conditions, use a Brookfield DV-III viscometer to measure the viscosity of the reusing agent solution at different times. At a certain moment, the change between the viscosity values of two adjacent measurements is not more than 5%, and this moment is the shear value. Dissolving time at shear rate. The viscosity of the solution depends on the stirring time figure 1 shown.

[0046] The experimental results show that the water-in-water cationic emulsion has better solubility properties, and the dissolution time at 20°C is 6-10 minutes. This is bec...

Embodiment 3

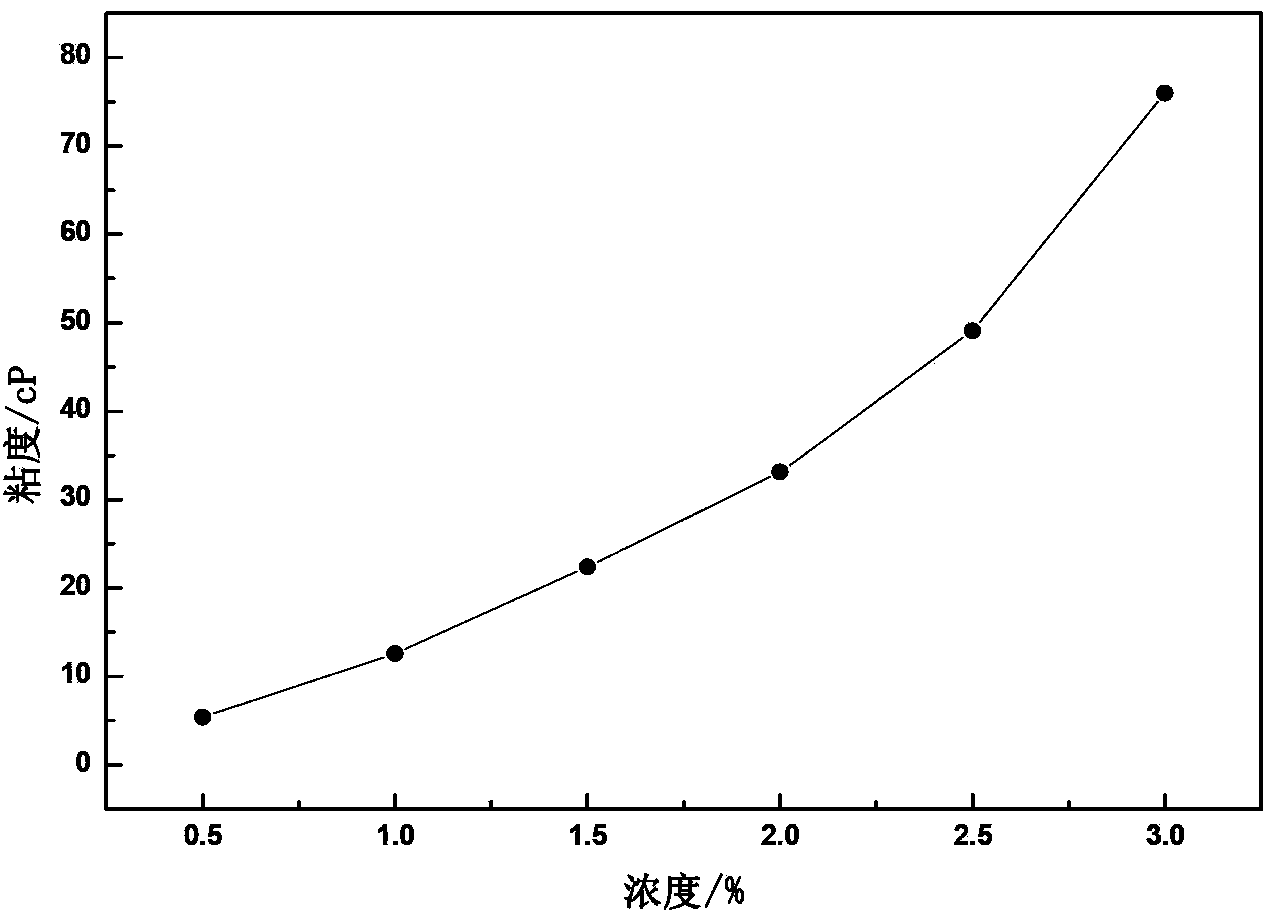

[0047] Example 3. Relation of Viscosity and Concentration of Regulating and Displacing Agents Reused by Formation Residual Polymers

[0048] Weigh 3.0g of the water-in-water cationic emulsion WF40 described in Example 1 and add it to the formation injection water described in 97.0g of Example 1, stir and dissolve for 10min under the condition of 400r / min, and prepare a mass concentration of 3%. Reuse the mother solution of the flood control agent, and then dilute it into the target solution with a mass concentration of 0.5%, 1.0%, 1.5%, 2.0%, and 2.5%. At 20°C and 7.34s - Under 1 condition, measure the viscosity value of solution with Brookfield viscometer, the results are shown in figure 2 . Depend on figure 2 It can be seen that the viscosity of the reutilization control agent for formation residual polymer increases exponentially with the increase of concentration. When the mass concentration is 1.5%, the viscosity is 22.4mPa·s, which shows that it has good injectabilit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com