Method for observing deformation of blast furnace

A deformation, blast furnace technology, applied in blast furnaces, blast furnace details, furnaces, etc., can solve the problems of reducing the measurement time and reducing the accuracy of the measurement results, unable to directly measure the change point, and unable to mix the two data to calculate, saving costs and reducing investment. , reducing the effect of the environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

[0028] Taking the deformation measurement of No. 10 blast furnace in a steel plant as an example, the specific operation steps are as follows:

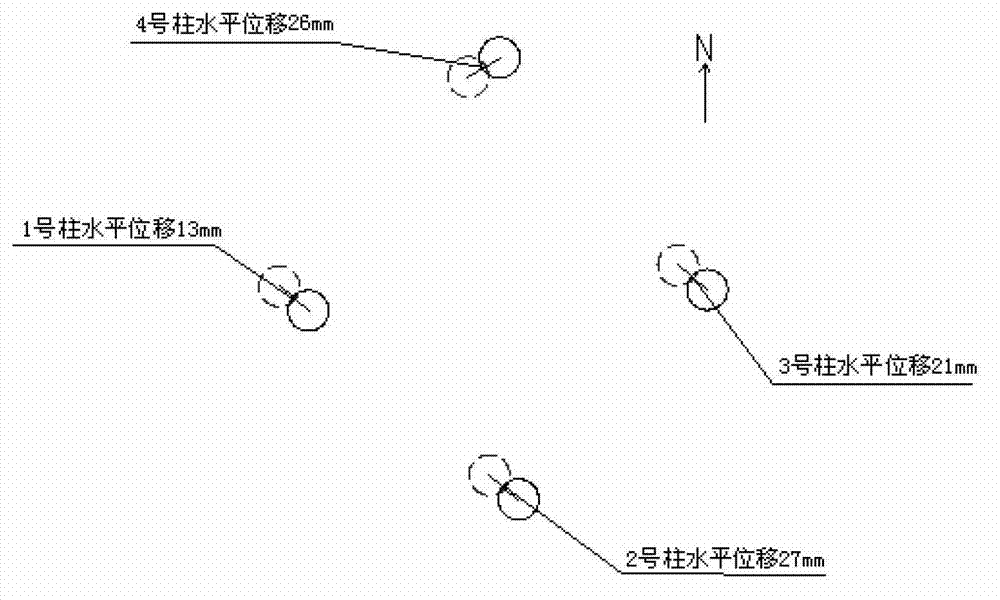

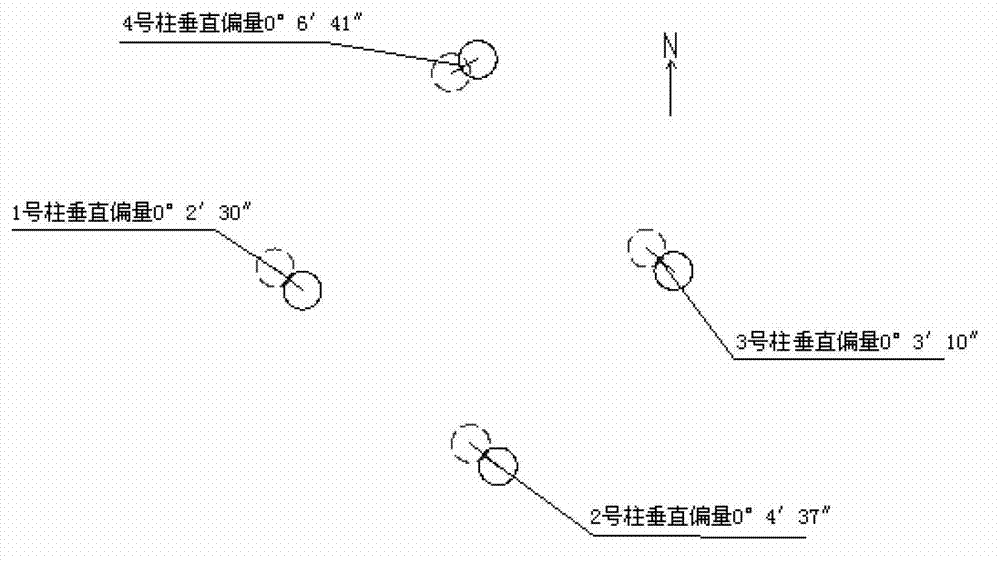

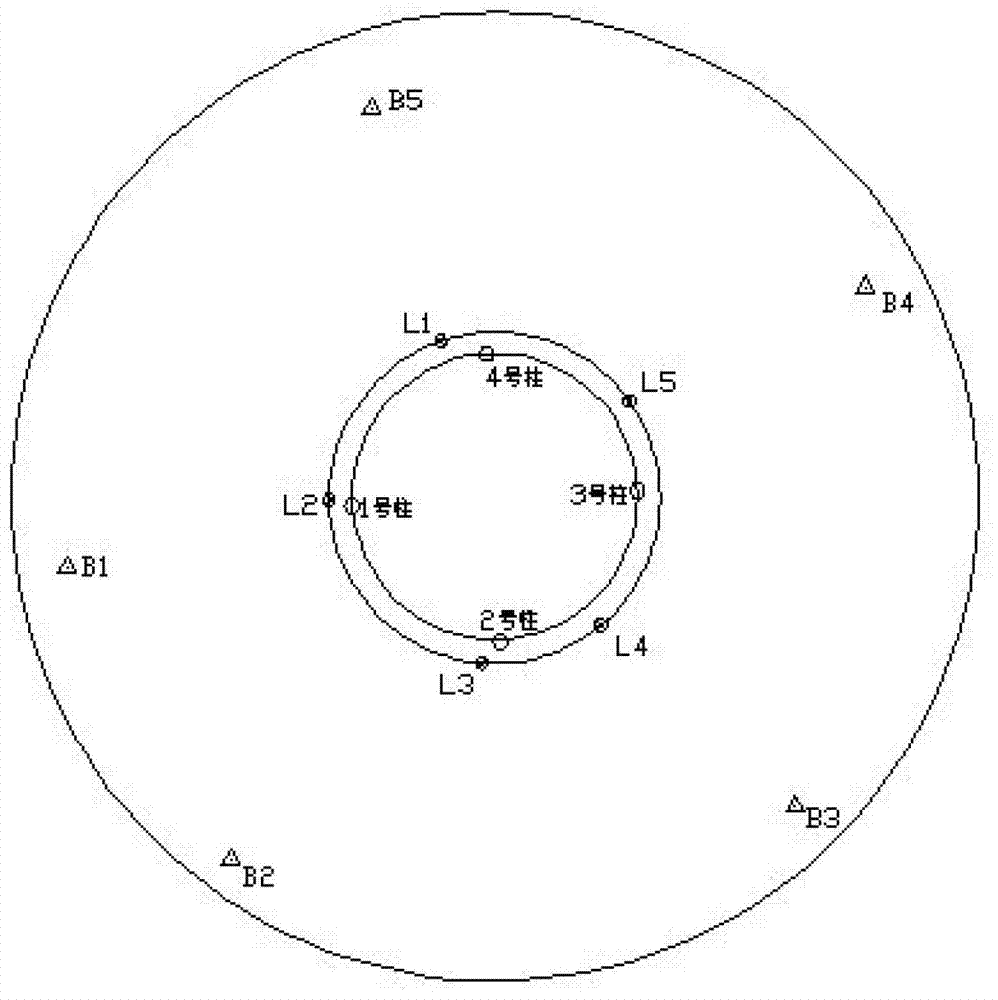

[0029] 1) Select four pillars (No. 1, No. 2, No. 3, and No. 4 pillars) and a crane beam on the foundation of the blast furnace as deformation observation objects, and illustrate by observing the deformation of the four pillars and a crane beam Deformation of blast furnace body;

[0030] 5 ground control points are arranged on the blast furnace ground: B1, B2, B3, B4, B5. See figure 1 ; Ground control points are marked on the concrete floor with steel nails. Each ground control point should meet the requirements of the plane method and the elevation method respectively. , that is, point B1 observes the inclination of column No. 1, point B2 observes the inclination of column No. 2, point B4 observes the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com