Gun cartridge clip loading and firing device applicable to a plurality of gun types

A technology for firing devices and guns, applied in the field of firearms, can solve the problems of safety hazards, inability to clamp pistols, affecting the use of guns, etc., and achieve the effects of convenient installation and disassembly, reducing mutual damage, and reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

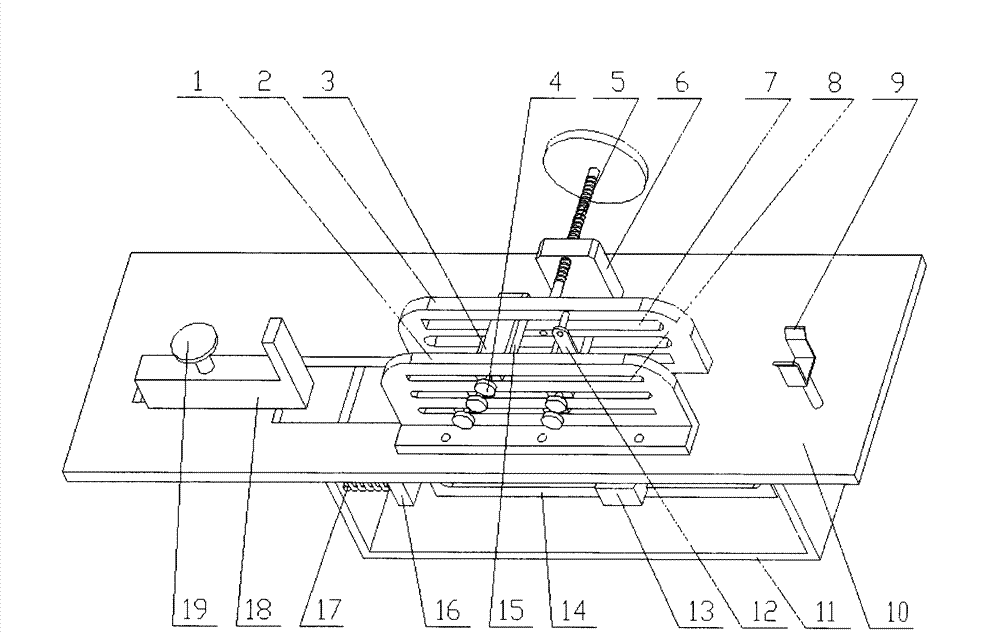

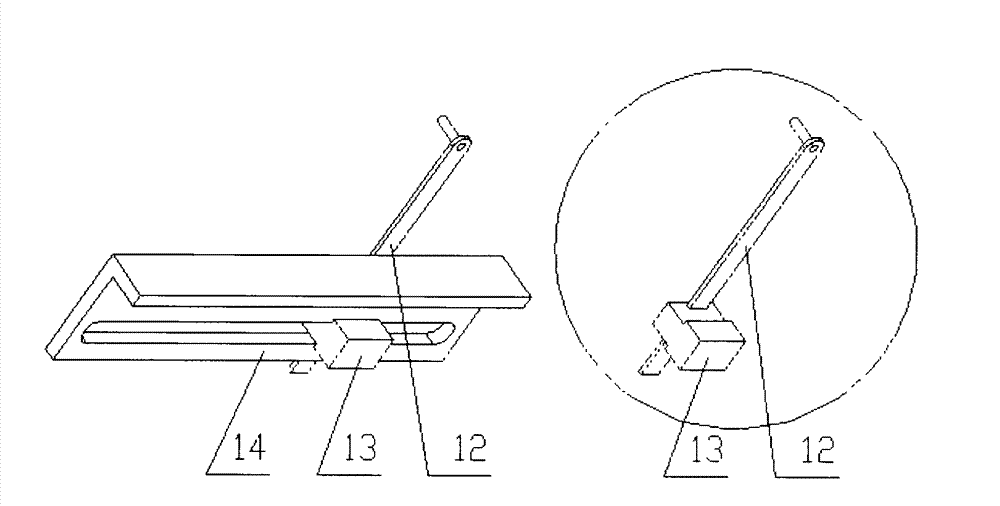

[0025] For a structural schematic diagram of a gun clamping and firing device suitable for multi-gun types according to the present invention, please refer to the attached figure 1 A gun clamping and firing device suitable for multiple guns is at least composed of a clamping part, a firing part and a base part. The clamping part at least includes a fixed side plate 1, a moving side plate 2, a clamping block 3, a knob 4, a driving rod 5, and a fixing seat 6; the firing part at least includes an inverted L-shaped driving bar 12, a trigger driving slider 13. The bracket 14 is composed of an inverted L-shaped driving bar 12, the trigger driving slider 13, and the bracket 14 are connected sequentially; The fixed side plate 1 and the movable side plate 2 of the clamping part are provided with at least two or more notches, the notch 7, the notch 8, the fixed side plate 1 of the clamping part and the base plate 10 of the base part Fixedly connected, the movable side plate 2, the driv...

specific Embodiment 2

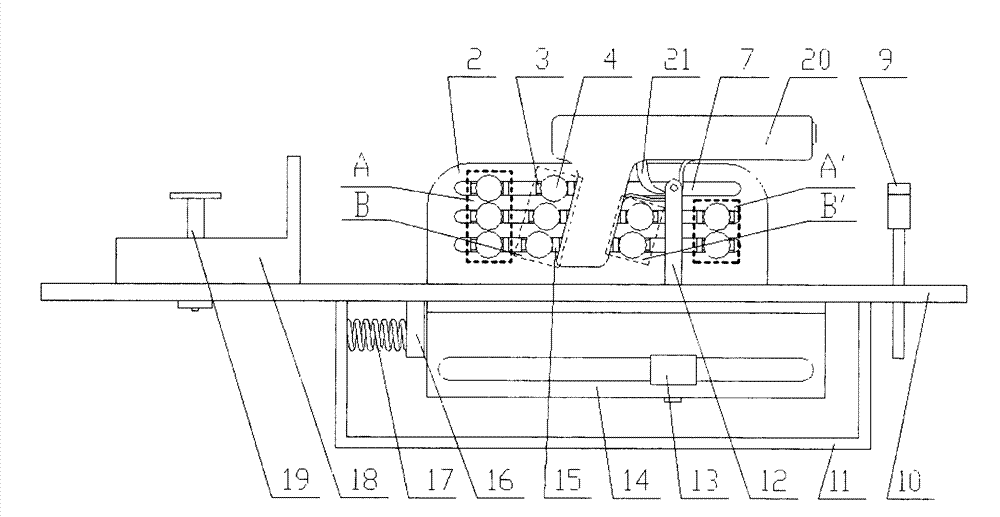

[0034] Another structural schematic diagram of a specific embodiment of the present invention is shown in the attached Figure 5 , its function and principle are the same as figure 1 unanimous. due to attachment Figure 5 The design and design of the fixed side plate 1 and the movable side plate 2 in the given structure figure 1 different, corresponding changes have been made to some structures, attached Figure 5 Replace the small clip 3.1 and the large clip 3.2 figure 1 Clamp block 3 in; attached Figure 5 Replacement of small knob 4.1 and large knob 4.2 in figure 1 Knob 4 in the Figure 5 Replacement of large notch 7.1 and small notch 7.2 on center moving side plate 2 figure 1 Notch 7 in; attached Figure 5 Replacement of large notch 8.1 and small notch 8.2 on center side plate 1 figure 1 notch 8 in the Figure 5 Among them, the device is at least composed of a clamping part, a firing part and a base part, and it also includes an additional buffer part and an auxi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com