An Online Adaptive Modeling Method for Hydrocyanic Acid Production Process

A technology of production process and modeling method, applied in the direction of adaptive control, instrumentation, control/regulation system, etc., can solve the problem that traditional methods cannot effectively establish high-precision models.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

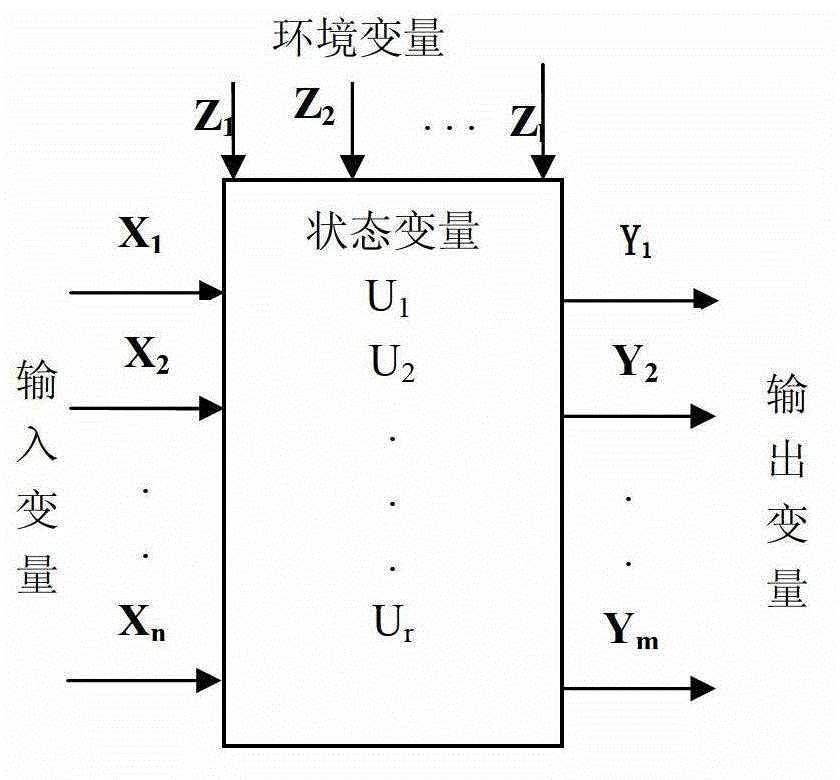

[0039] In the industrial production process of hydrocyanic acid, the system has input variables, environment variables, and internal state variables, such as figure 1 shown.

[0040] According to the system block diagram, its target performance conversion rate is a model of input variables, environmental variables and internal state variables:

[0041]

[0042] In fact, for the complex hydrocyanic acid industrial process, the environmental variable noise Z is often uncontrollable, and the internal state variable U is difficult to obtain. It is most realistic to optimize the output only by adjusting the input variable X. Therefore, usually we can only convert the full model of the system to an approximate approximation model in the input variable X subspace.

[0043]

[0044] In a certain environment and time, the environmental noise variable Z and the internal state variable U are relatively stable and can be considered as constants. At this point, we can obtain the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com