Temperature control method for reaction kettle

A temperature control method and reactor technology, applied in the direction of temperature control, self-adaptive control, general control system, etc., can solve problems such as poor temperature control, and achieve the effect of convenient operation of personnel and qualified product production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

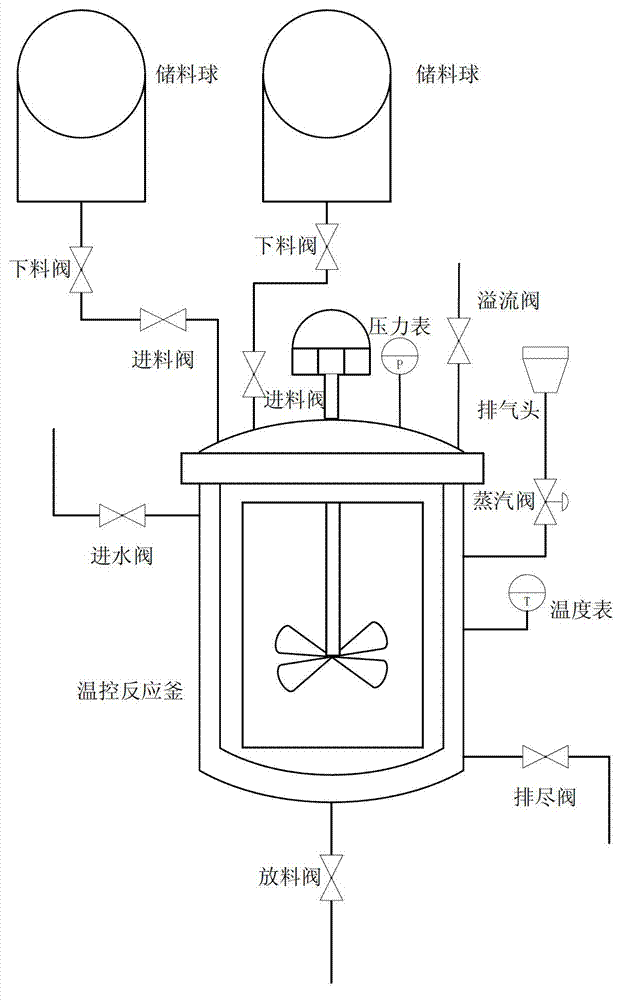

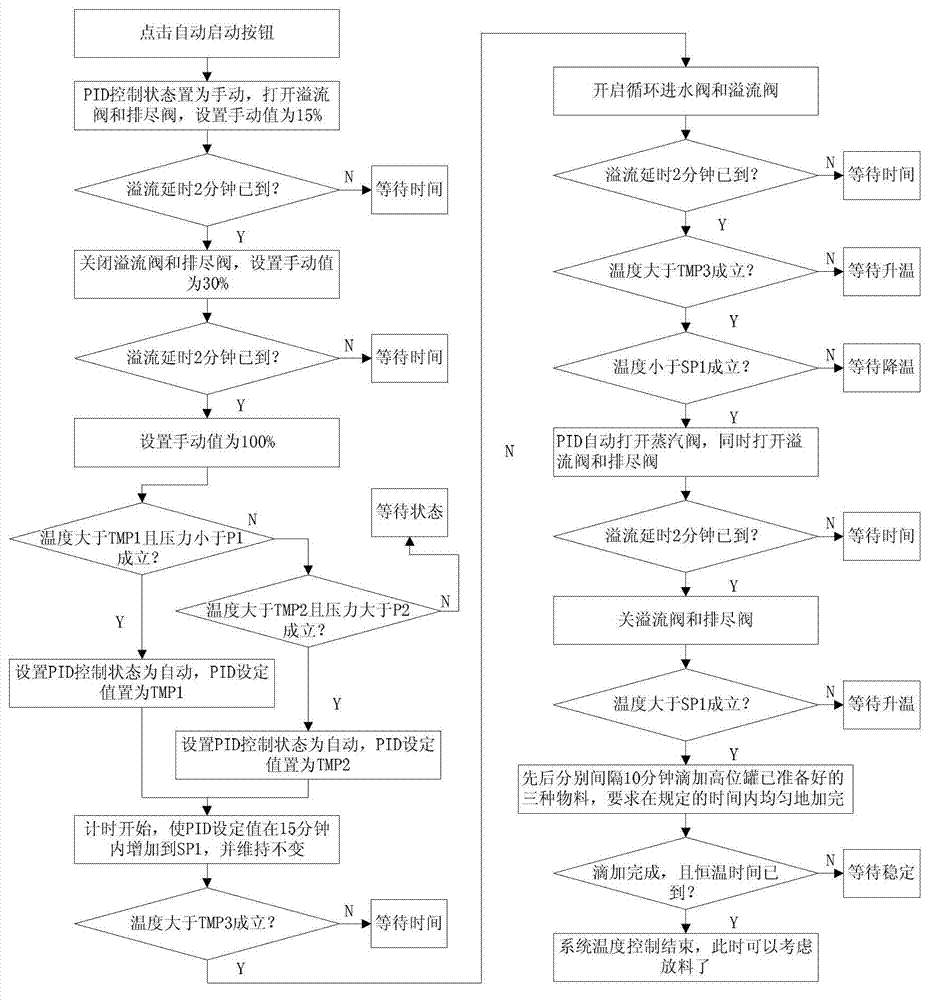

[0013] Example: such as figure 1 and figure 2 As shown, this embodiment provides a method for temperature control of the reactor, including two parts: the temperature-controlled reactor device and the specific implementation process of the temperature control of the reactor.

[0014] The temperature-controlled reactor equipment mainly includes the main component reactor, the important valve overflow valve, water inlet valve, exhaust valve and steam valve, and the auxiliary valve feeding valve and discharging valve. The important valve plays a key role in the control process of the whole system, and is used to control the temperature change of the reactor. Among them, the steam valve constitutes the control variable of the temperature control loop, and other valves assist in realizing the temperature control of the reactor.

[0015] The concrete realization steps of the temperature control method of reactor of the present invention are as follows:

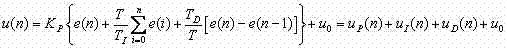

[0016] (1) Adopt the sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com