Self-calibration current source system

A self-calibration, current source technology, used in control/regulation systems, regulating electrical variables, instruments, etc., to solve problems such as performance degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Now further illustrate the present invention in conjunction with accompanying drawing. Those skilled in the art can understand that the following is a non-restrictive description of the gist of the present invention in conjunction with specific embodiments, the scope of the present invention is determined by the appended claims, and any modifications and changes that do not depart from the spirit of the present invention should be covered by the claims of the present invention.

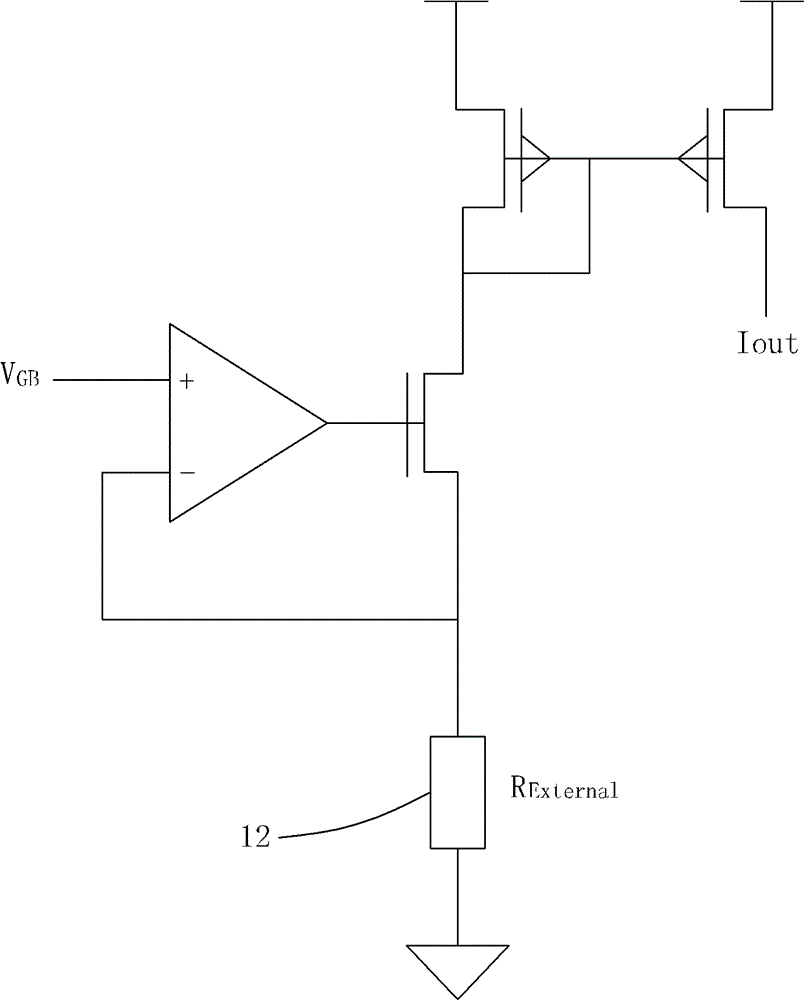

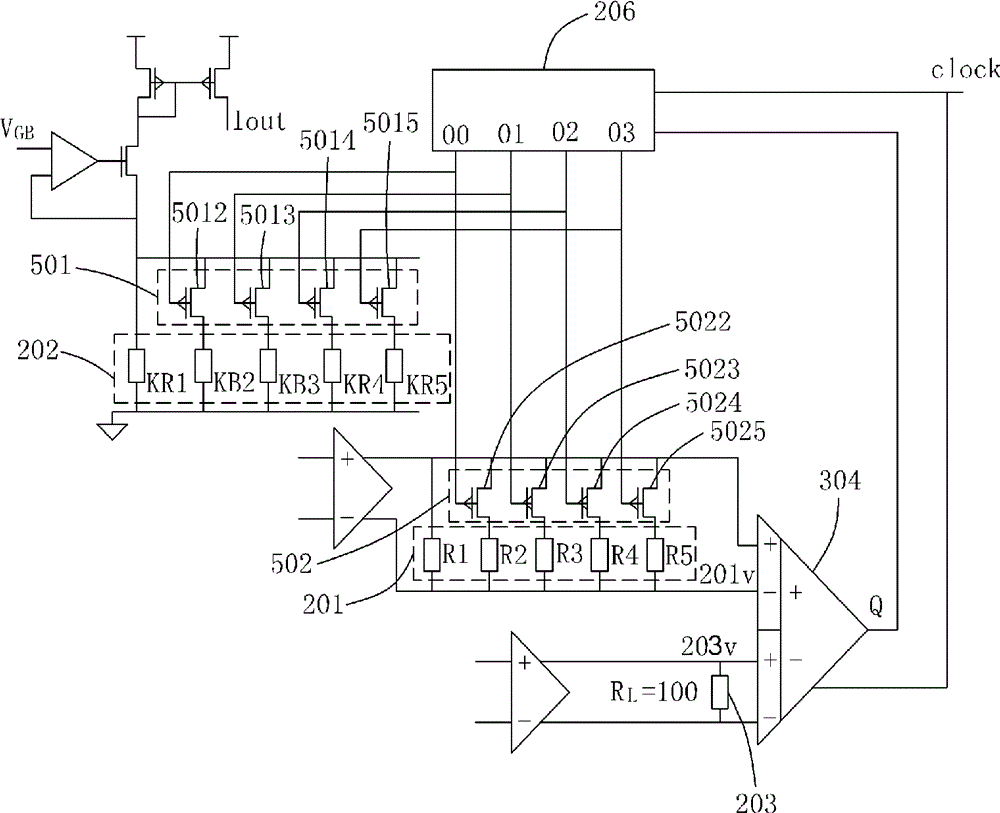

[0018] The focus of the present invention is to use the existing output terminal resistance of the chip as a reference resistance, and set a self-calibration resistance array inside the current source, so that the internal total resistance of the current source gradually approaches the reference resistance.

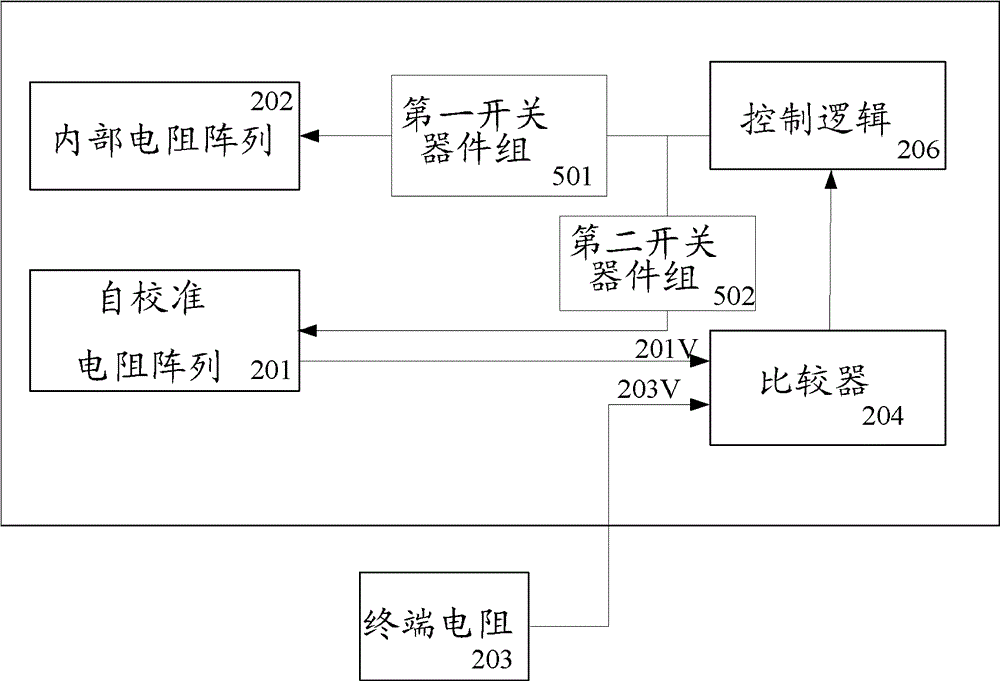

[0019] figure 2 is a schematic structural diagram of a self-calibrating current source system according to an embodiment of the present invention. As an example, this article uses the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com