Axial forcing device and adjustment method for winding displacement of superconducting coil

A technology of superconducting coils and force devices, which is applied in superconducting magnets/coils, coil manufacturing, transportation and packaging, and can solve the problem that the inter-turn gap of superconducting wires cannot be accurately and effectively controlled.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

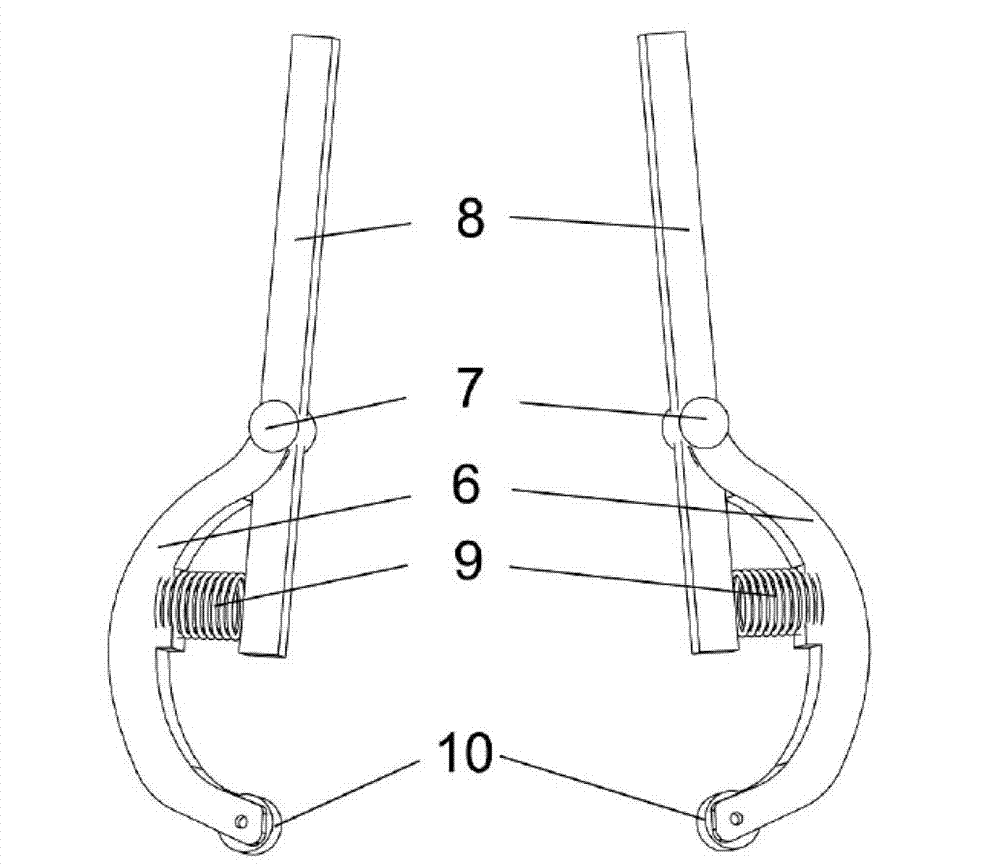

[0032] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

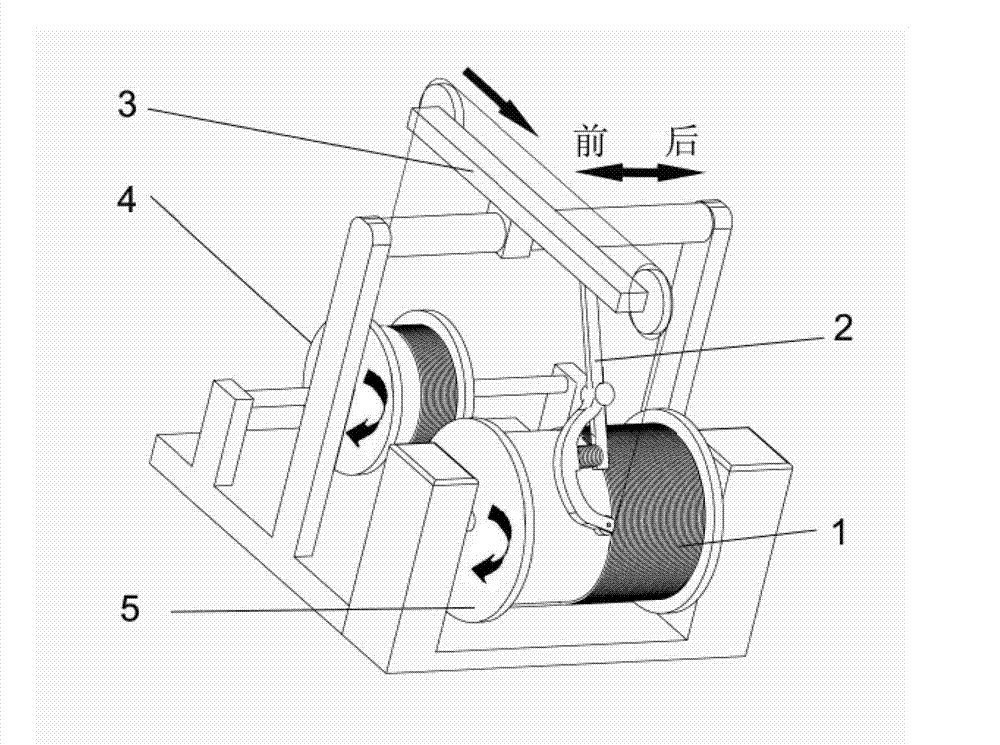

[0033] The winding process of the superconducting coil 1 is: the superconducting wire on the pay-off shaft 4 is driven by the motor, and is regularly wound on the winding shaft 5 by the winding frame 3 of the winding machine to form the superconducting coil 1 .

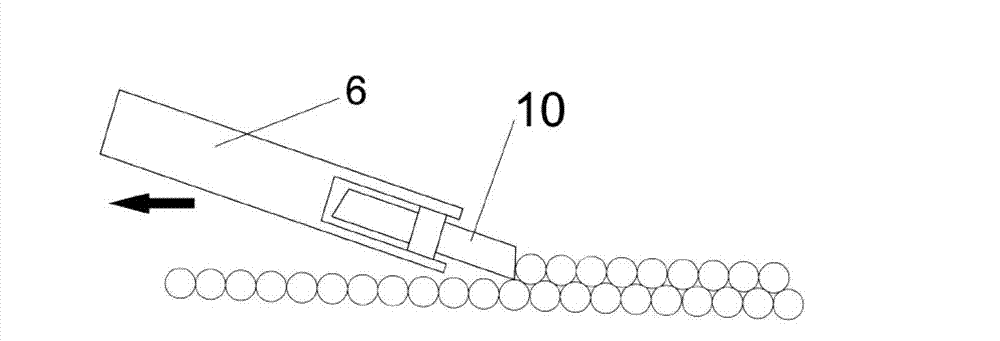

[0034] In the currently commonly used superconducting coil winding system, there is no axial cable arrangement, such as Figure 5 shown. The control of the axial turn-to-turn gap of the superconducting coil 1 can only be accomplished by two methods. One is to indirectly drive and control the axial gap of the lower superconducting coil through the axial movement of the cable rack. However, because it is not directly controlled, the effect of this control on the compaction of the wire is not significant, and it is easy to cause the increase of the inter-turn gap. The second is to squee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com