Circuit board of vehicle electrical appliance concentrated distribution box

A technology for power distribution boxes and circuit boards, which is applied to printed circuits, printed circuit components, electrical components, etc., can solve problems such as high heat generation, poor reliability, and high line density, and achieve large current interception capacity, low heat generation, and low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

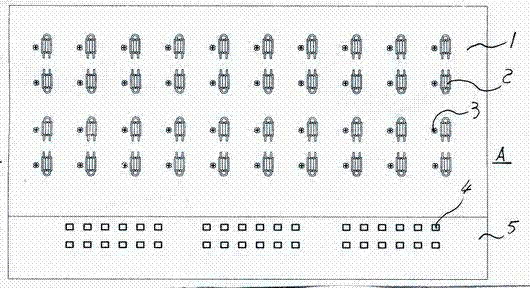

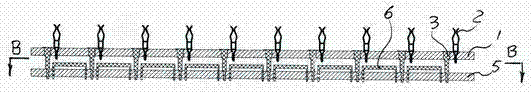

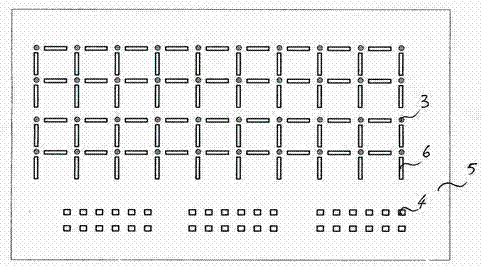

[0010] In order to solve the defect that the existing printed circuit board does not have low heat generation under high current load and low process cost, the present invention adopts the following technical scheme. There are two printed circuit boards of the present invention, and 2 automotive standard fuses or relay sockets are used The wave soldering process is welded on the upper printed circuit board 1, and the rivetable conductive post 3 is riveted on the upper printed circuit board. The above-mentioned socket and the conductive post are respectively exposed on the upper surface and the lower surface of the upper printed circuit board. The upper surface of the lower printed circuit board in between is provided with a square distribution of conductive strips 6, the bent feet at both ends of the conductive strips are inserted into the holes of the lower printed circuit board and the pad holes at both ends of the holes, and the conductive columns and conductive strips are co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com