Method for adjusting the rotational speed of a wind turbine and wind turbine

A technology of wind energy equipment and rotational speed, which is applied in wind energy power generation, mechanical equipment, control of wind turbines, etc., and can solve problems such as loss of income

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In the following figures, identical or identical types of elements or corresponding components are each provided with the same reference numerals, so that a corresponding repeated description is omitted.

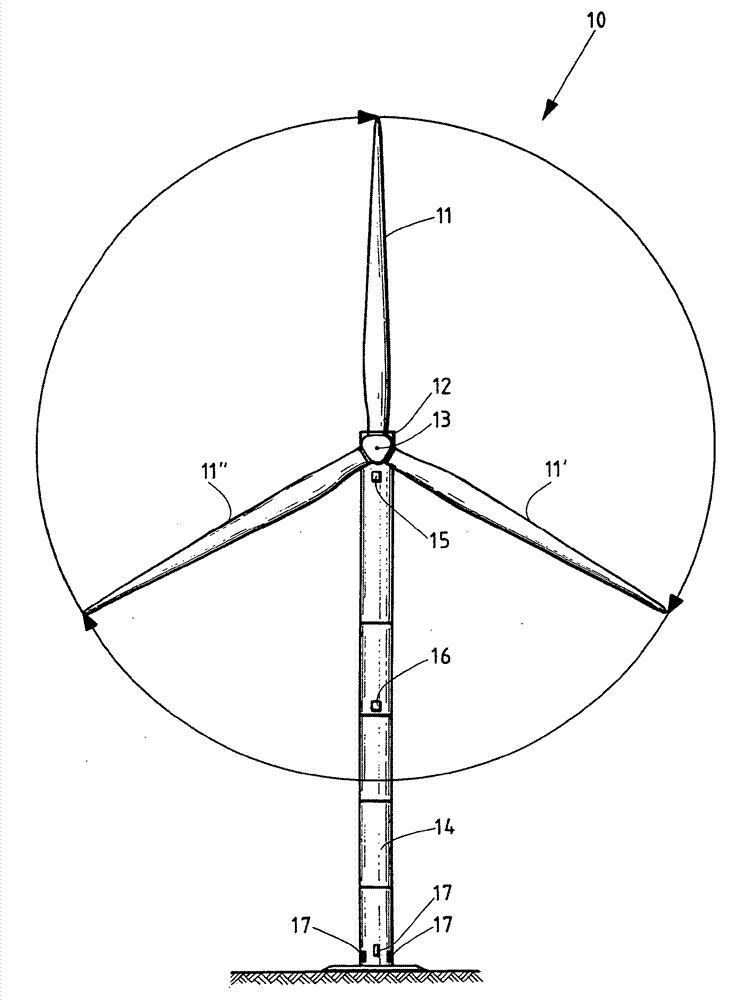

[0021] FIG. 1 schematically shows a wind energy installation 10 with a rotor 13 comprising three rotor blades 11 , 11 ′, 11 ″, which are designed circumferentially in the direction of the arrow. The rotor 13 is seated at the machine housing 12 above the tower 14 . Sensors 15 , 16 and 17 are provided which can detect vibrations or vibration levels of the tower or wind energy installation. In this case, for example, acceleration sensors or strain gauges can be involved. Preferably, strain gauges are arranged in the region of the tower base at sensor 17 and acceleration sensors are arranged centrally at 16 and in the upper region of tower 14 at 15 . At a corresponding height, it is also expedient to use a plurality of sensors, for example three, four or more sensors, w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com