Device for mitigating serious accidents for a nuclear fuel assembly, with improved effectiveness

A technology for nuclear fuel assemblies and nuclear fuel rods, applied in the assembly of fuel elements, emergency protection devices, nuclear engineering, etc., can solve the problems of delayed passive safety device effect, long trigger time, passive safety device failure, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

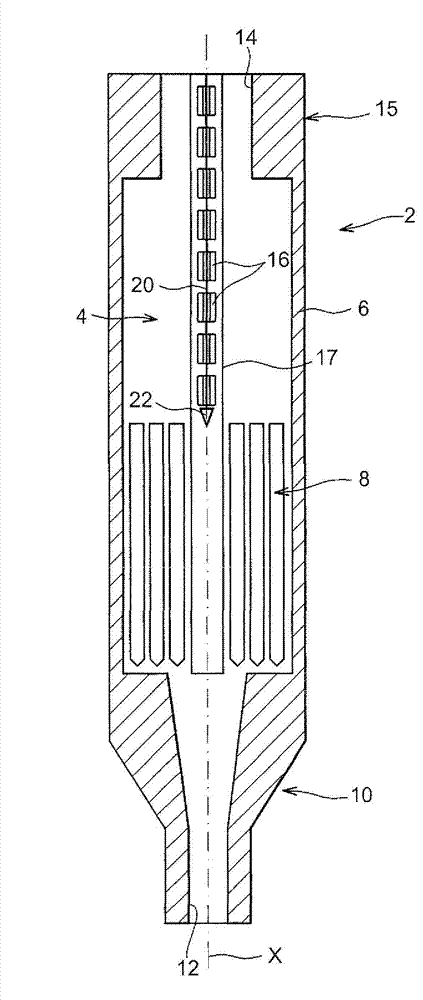

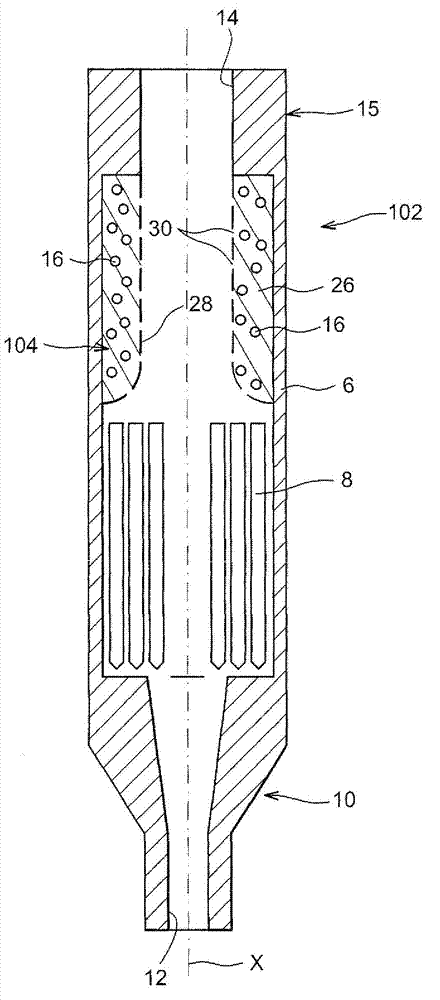

[0031] figure 1 A nuclear fuel assembly 2 comprising a passive safety device 4 according to a first embodiment is shown very schematically.

[0032] This assembly comprises a casing 6 having a longitudinal axis X and generally having a hexagonal cross-section, and nuclear fuel rods 8 arranged substantially in the middle part of said casing.

[0033] The assembly is typically mounted through its lower portion 10 (referred to as the bottom of the assembly) into a core grid (not shown) that supports this assembly and other assemblies, and that provides liquid metal cooling to these assemblies agent. The assembly comprises a liquid metal inlet 12 in the lower part and a liquid metal outlet 14 in the upper part, the liquid metal being delivered by a pump. Thus, the liquid metal circulates from the bottom to the top of the assembly and extracts the heat generated by the fission reaction from the rods.

[0034] The passive safety device 4 according to the invention is arranged in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com