Soldering tin melting furnace

A melting furnace and soldering technology, applied in the direction of tin feeding device, welding equipment, material removal/addition, etc., can solve problems such as dangerous operation, difficult recycling, difficulty, etc., to prevent hand burns, improve safety, and increase fault tolerance rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

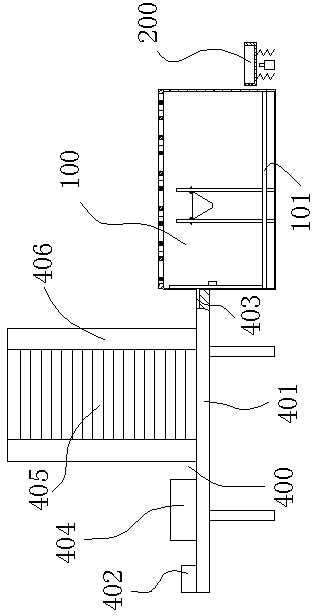

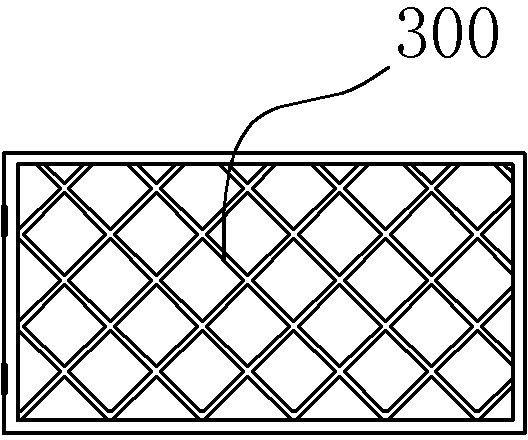

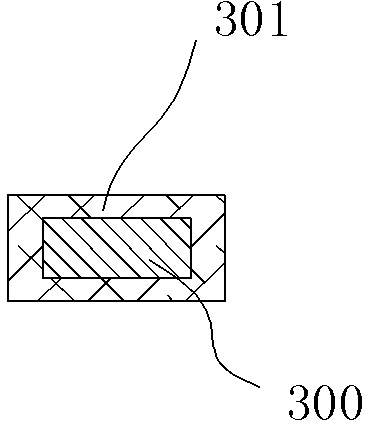

[0023] Embodiment 1, a solder melting furnace, comprising a heat-resistant cavity 100 with an opening on one side, a waste recovery tray 200 is arranged next to the heat-resistant cavity 100, and a first heating wire 101 is installed inside the heat-resistant cavity 100 One side of the opening of the heat-resistant container cavity 100 is provided with a mesh cover 300 connected by rotation. The mesh cover 300 is set on the heat-resistant container cavity 100 so that the worker's hands cannot be inserted into the heat-resistant container cavity 100, completely eliminating the possibility of the worker's hand touching the container. The possibility of solder liquid in the cavity 100 improves the safety performance. The outer side of the net cover 300 is wrapped with a first heat insulation layer 301 , the first heat insulation layer 301 can be set to reduce the temperature of the net cover 300 , and it is safer for workers to touch the net cover 300 without feeling hot.

[0024...

Embodiment 2

[0027] Embodiment 2, a solder melting furnace, comprising a heat-resistant cavity 100 with an opening on one side, a waste recovery tray 200 is arranged beside the heat-resistant cavity 100, and a first heating wire 101 is installed inside the heat-resistant cavity 100 One side of the opening of the heat-resistant container cavity 100 is provided with a mesh cover 300 connected by rotation, and the mesh cover 300 is set on the heat-resistant container cavity 100 so that the worker's hand cannot be inserted into the heat-resistant container cavity 100, completely eliminating the possibility of the worker's hand touching the container. The possibility of solder liquid in the cavity 100 improves the safety performance. The outer side of the net cover 300 is wrapped with a first heat insulation layer 301 , the first heat insulation layer 301 can be set to reduce the temperature of the net cover 300 , and it is safer for workers to touch the net cover 300 without feeling hot.

[00...

Embodiment 3

[0031] Embodiment 3, a solder melting furnace, comprising a heat-resistant cavity 100 with an opening on one side, a waste recovery tray 200 is arranged next to the heat-resistant cavity 100, and a first heating wire 101 is installed inside the heat-resistant cavity 100 One side of the opening of the heat-resistant container cavity 100 is provided with a mesh cover 300 connected by rotation. The mesh cover 300 is set on the heat-resistant container cavity 100 so that the worker's hands cannot be inserted into the heat-resistant container cavity 100, completely eliminating the possibility of the worker's hand touching the container. The possibility of solder liquid in the cavity 100 improves the safety performance. The outer side of the net cover 300 is wrapped with a first heat insulation layer 301 , the first heat insulation layer 301 can be set to reduce the temperature of the net cover 300 , and it is safer for workers to touch the net cover 300 without feeling hot.

[0032...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com