Cutting method and cutting system of single-layer array glass substrate

A technology of glass substrate and cutting method, which is applied in the field of single-layer array glass substrate cutting method and cutting system, can solve the problems of low yield rate of finished products, physical damage of chuck, splashing glass particles, etc., and save the process of adjusting wheel base, Reduce the difficulty of cleaning and ensure the quality of finished products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

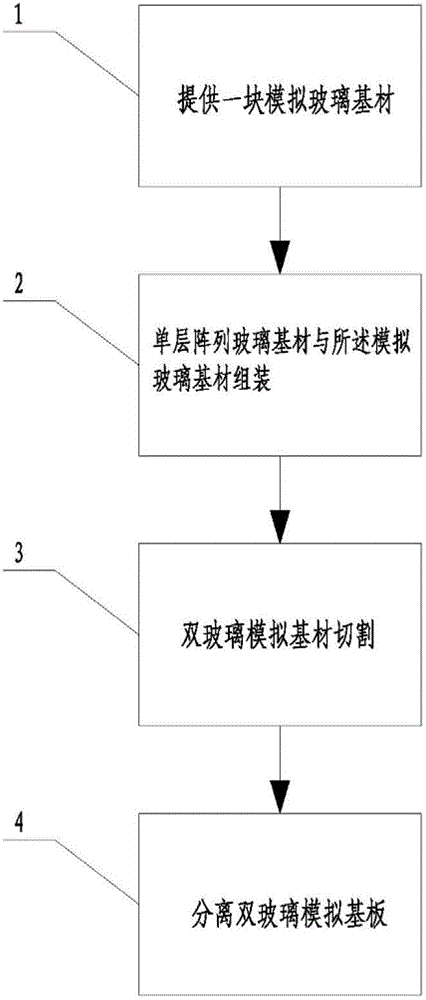

[0032] see figure 1 As shown, the cutting method of the single-layer array glass substrate in this embodiment includes the following steps:

[0033] 1. A simulated glass substrate is provided; the simulated glass substrate described in this embodiment adopts an ordinary glass substrate.

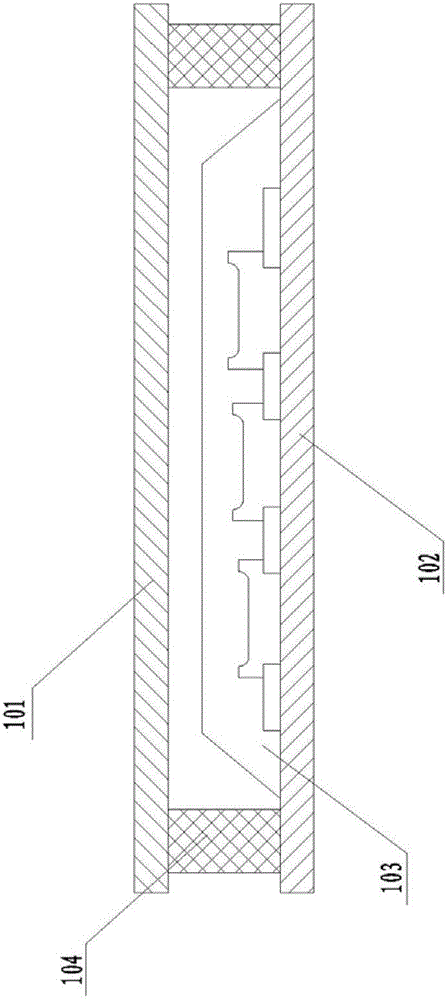

[0034] 2. The single-layer array glass substrate after the array process and the simulated glass substrate are assembled into a double-glass simulated substrate through an alignment process by an alignment machine; the double-glass simulated substrate described in this embodiment includes The simulated glass substrate on the upper layer and the single-layer array glass substrate on the lower layer are distributed with a plurality of array units arranged according to design requirements, and the simulated glass substrate and the single-layer array glass substrate Connected by sealant applied between the two; thereby well protecting the array elements within the dual glass mock-up substrate; p...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap