Rotation valve driving device

A driving device and valve technology, applied in the direction of valve device, valve operation/release device, valve details, etc., can solve problems such as inconsistency of opening and closing torque characteristic curves, unsuitable for remote control, unsuitable for large-diameter ball valves, etc., to achieve volume Small size, simple structure, large output torque effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

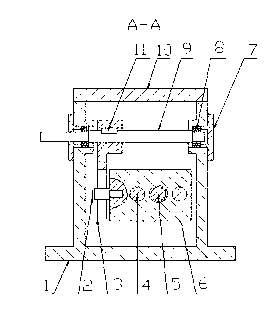

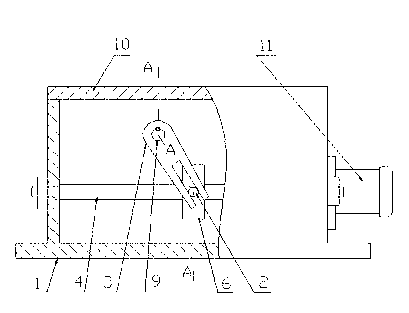

[0009] In the figure, the invention includes a box body 1, a dial shaft 2, a shift fork 3, a guide rod 4, a screw 5, a slider 6, a right bearing cover 7, a bearing 8, a drive shaft 9, a case cover 10, and a servo motor 11 , the invention is provided with a box body 1 with a box cover 10 on the top, a servo motor 11 is fixed on one side of the box body 1, and two rod-shaped guide rods 4 and a lead screw 5 are traversed inside the box body 1. A slide block 6 is slidably installed on the guide rod 4, and a dial shaft 2 is respectively arranged on both sides of the slide block 6, and a shift fork 3 is inserted into the shift shaft 2, and a drive shaft 9 is fixed on the upper end of the shift fork 3 , the two ends of the drive shaft 9 are fixed with a bearing 8 through the right bearing cover 7 respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com