Single board temperature control device and method

A temperature control device and single board technology, applied in temperature control, non-electric variable control, control/regulation system, etc., can solve the problems of poor temperature control of optical modules, difficult installation of radiators, etc., and achieve low pressure and small structure , the effect of light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

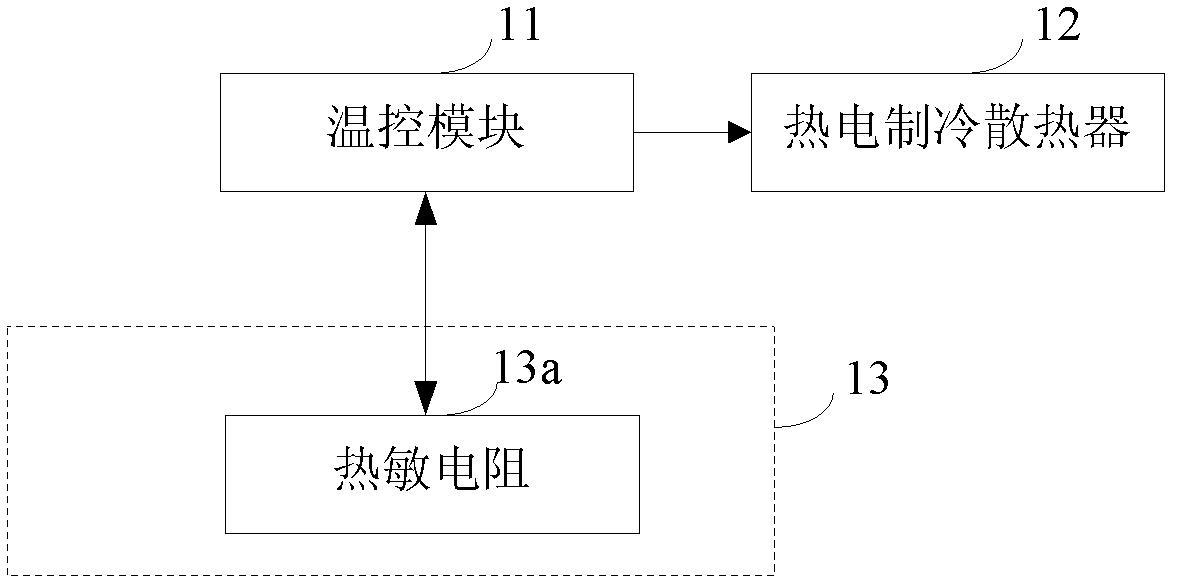

[0023] Such as figure 1 As shown, the embodiment of the present invention provides a single-board temperature control device, which is suitable for a single board with multiple optical modules 13. The single board is provided with a housing for the optical modules 13 to be plugged in. The device includes: installed on The radiator on the housing, the thermistor 13a arranged on the optical module 13, and the temperature control module 11, the radiator includes at least one thermoelectric cooling radiator 12, and the thermoelectric cooling radiator 12 is installed at least on the air outlet side of the single board The temperature control module 11 is electrically connected to the thermoelectric cooling radiator 12 and the thermistor 13a respectively, and is used to control the input power of the corresponding thermoelectric cooling radiator 12 according to the measured value of the thermistor 13a.

[0024] Specifically, the thermistor 13a may be a device built into the optical ...

Embodiment 2

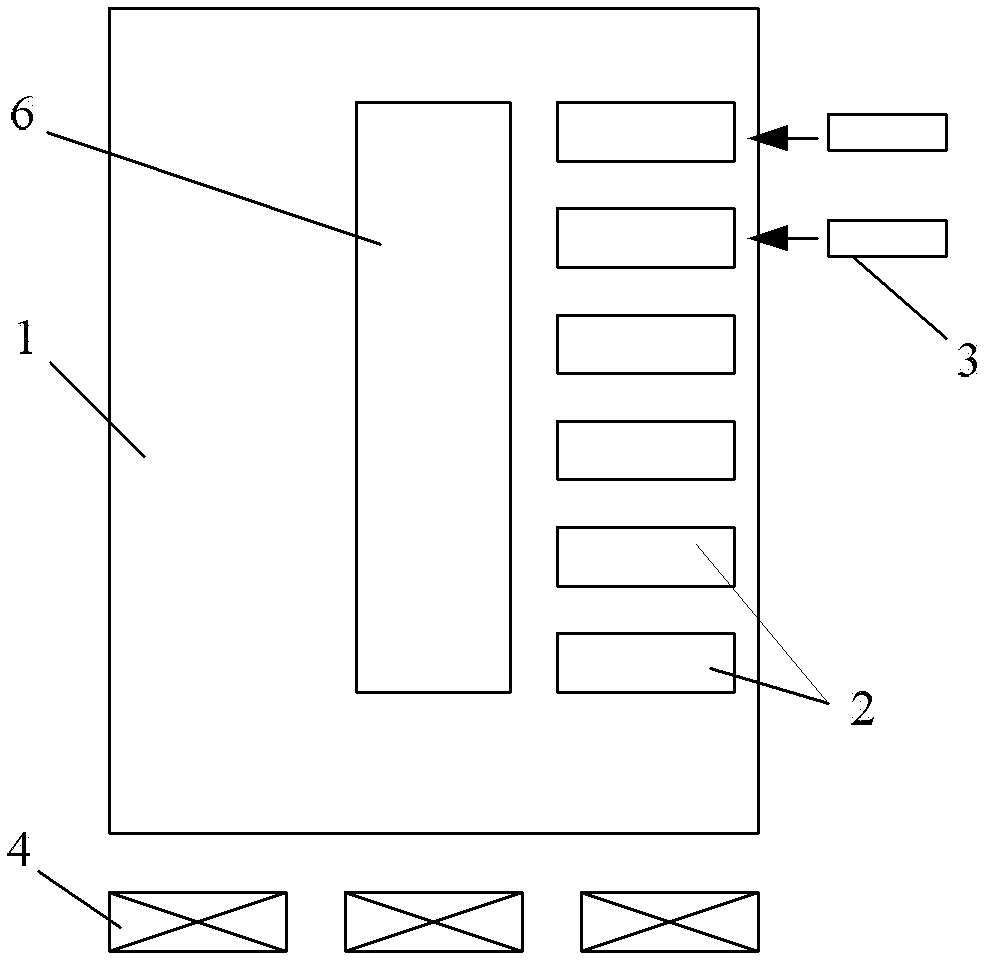

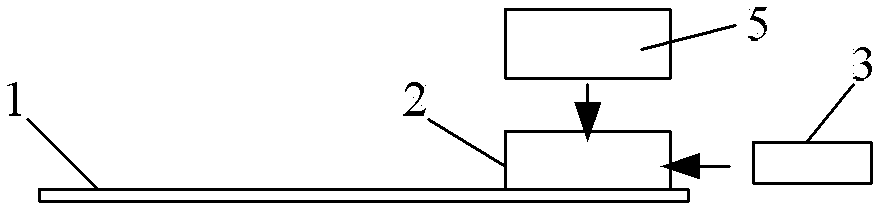

[0027] In order to facilitate the understanding of this embodiment, the following first combines Figure 2a-2b with image 3 This section briefly introduces the composition and structure of boards and optical modules. Such as Figure 2a-2b As shown, the single board 1 is provided with a plurality of housings 2 for plugging in and out of the optical modules 3 . A heat dissipation fan 4 is provided on one side of the single board 1 for providing cooling airflow, and the direction indicated by the thick arrow in the figure is the airflow direction of the heat dissipation fan 4 . The airflow passes through each optical module to take away the heat generated by the optical module, and dissipates heat for the optical module 3 . combine image 3 , the optical module 3 usually includes an optical communication device 31, a second thermoelectric cooling chip 33 and a thermistor 32, wherein the optical communication device 31 is a heating device, the thermistor 32 is used to detect ...

Embodiment 3

[0040] In the embodiment of the present invention, a single-board temperature control method using the single-board temperature control device in Embodiment 1 is provided, such as Figure 5 As shown, the method includes:

[0041] Step 501: Obtain the temperature of the optical module through the thermistor.

[0042] Specifically, the thermistor may be a component of the optical module.

[0043] Step 502: Adjust the input power of the thermoelectric cooling radiator installed on the housing of the optical module according to the temperature of the optical module.

[0044] Specifically, as mentioned above, the input power of the thermoelectric cooling chip can be controlled by changing the magnitude and direction of the current, or changing the voltage.

[0045] Further, the single-board temperature control device may also include: a second thermoelectric cooling chip disposed on the optical module, and the temperature control module is also electrically connected to the secon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com