Case hardened steel and method for producing same

A manufacturing method, a technology of hardening steel, applied in the direction of manufacturing tools, furnace types, furnaces, etc., can solve problems such as insufficient cold forgeability, and achieve the effects of shortened order cycle, good cold forgeability, and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0061] Hereinafter, the present invention will be described more specifically with reference to examples. The present invention is not limited to the following examples, and can of course be appropriately modified and implemented within the scope of meeting the above-mentioned and hereinafter-described purposes, and these are included in the technical scope of the present invention.

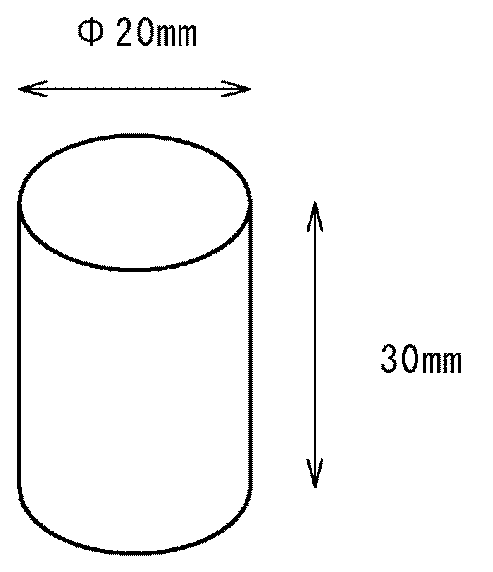

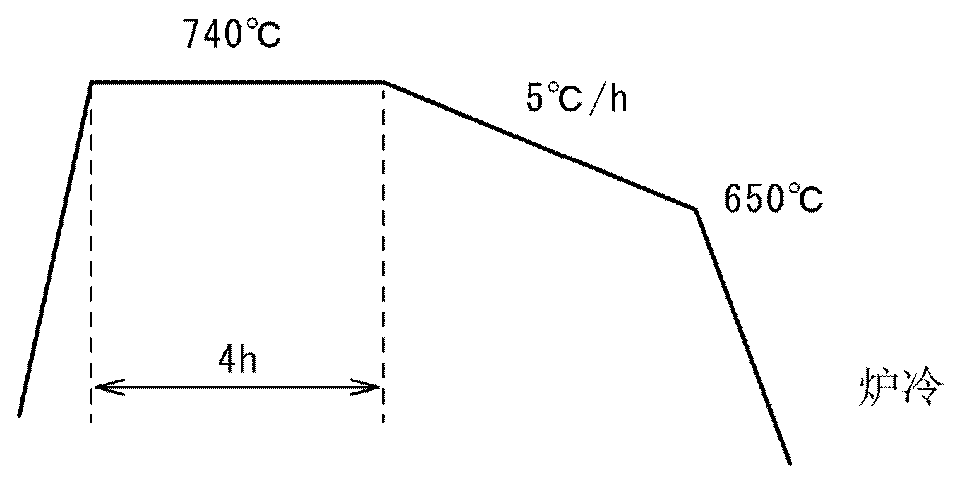

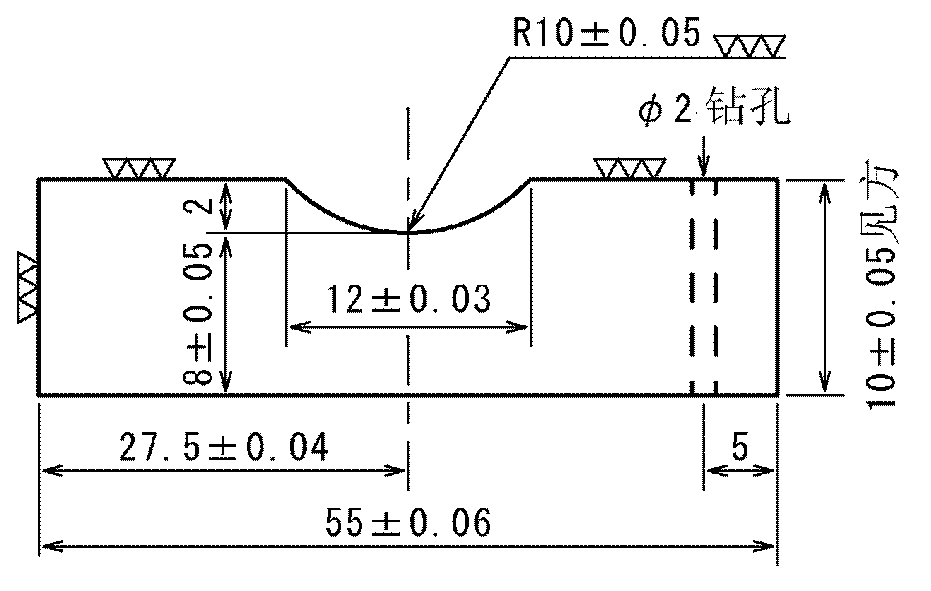

[0062] Following the usual smelting method, melt the steel with the chemical composition shown in Tables 1 to 3, after casting, hot forge after soaking (simulating the above-mentioned billet rolling) and cool to room temperature (cooling rate is 5°C / s ). Afterwards, reheat and carry out forging for the first time (simulation above-mentioned hot rolling for the first time), after cooling to forging temperature for the second time (simulation above-mentioned hot rolling for the second time), carry out forging for the second time and cool to room temperature ( The cooling rate was 5° C. / sec), and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com