High-efficient powder selecting machine

A kind of powder separator, high-efficiency technology, applied in agricultural machinery equipment, solid separation, separating solids from solids with air flow, etc., can solve the problem that the stator angle of the powder separator cannot be adjusted, which is unfavorable for energy saving and consumption reduction, and cannot form classification force field etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further explain the technical means and effects that the present invention takes to achieve the intended purpose of the invention, below in conjunction with the accompanying drawings and preferred embodiments, its specific implementation, structure, features and effects of the high-efficiency powder separator proposed according to the present invention , as detailed below.

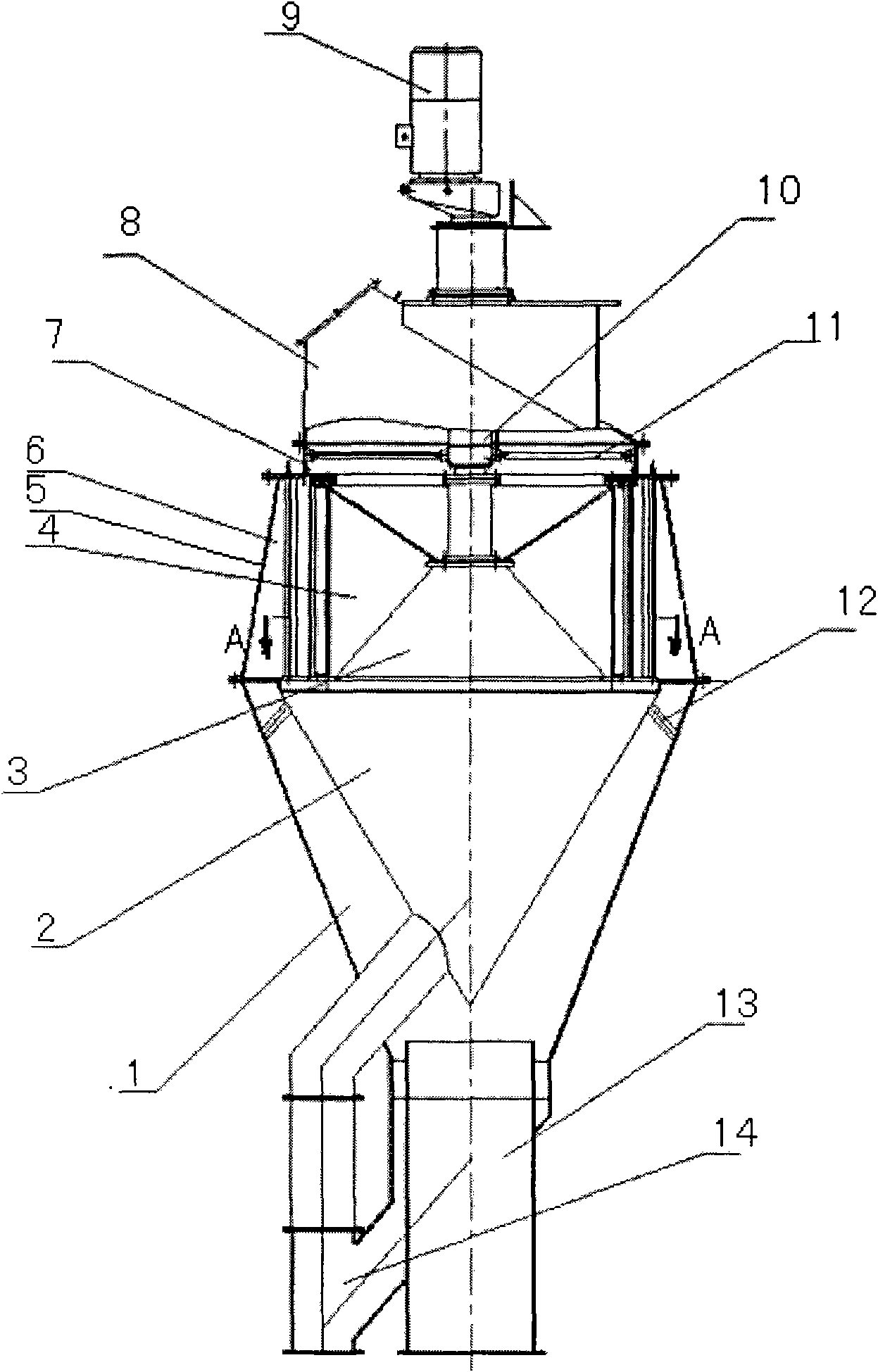

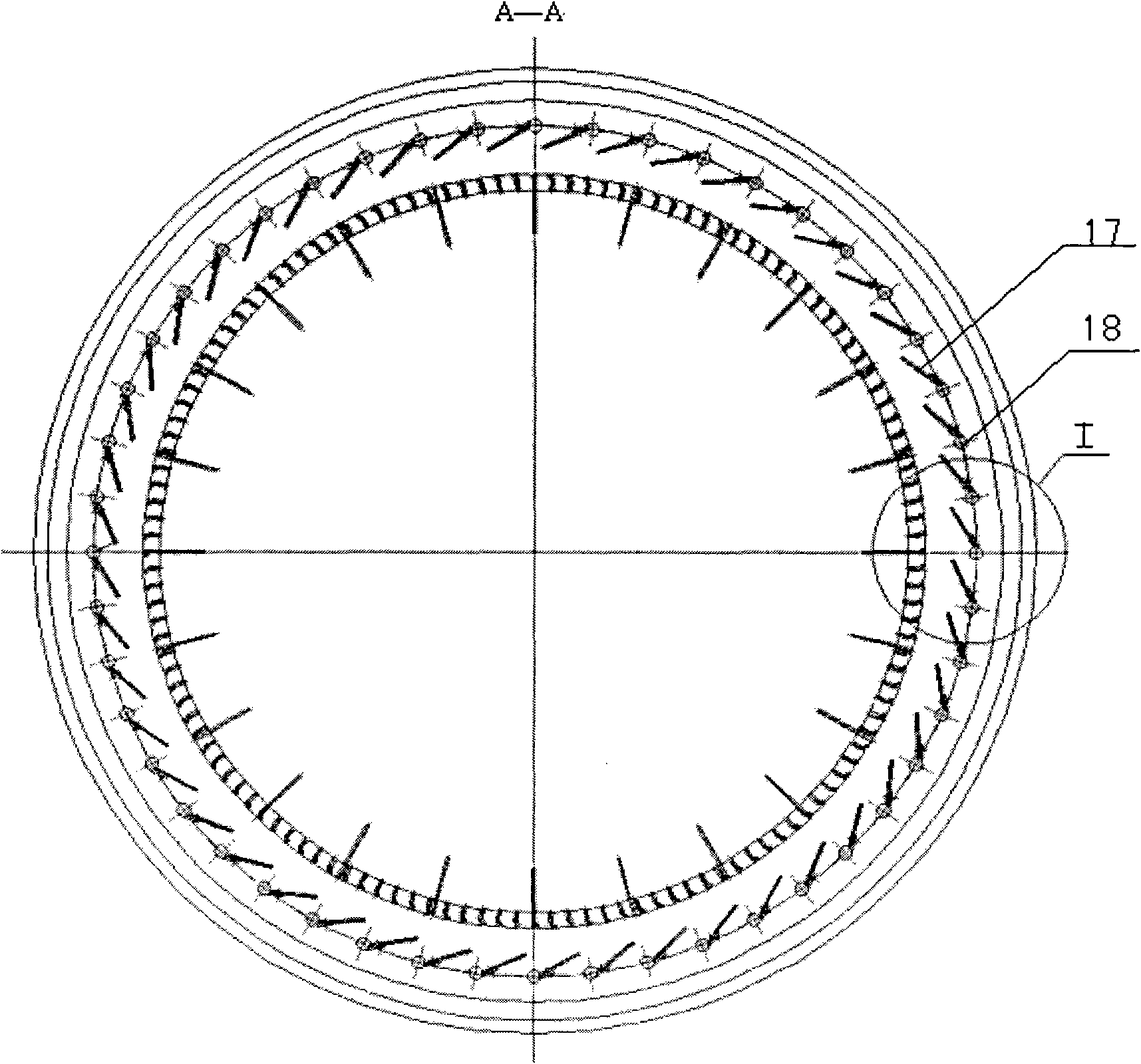

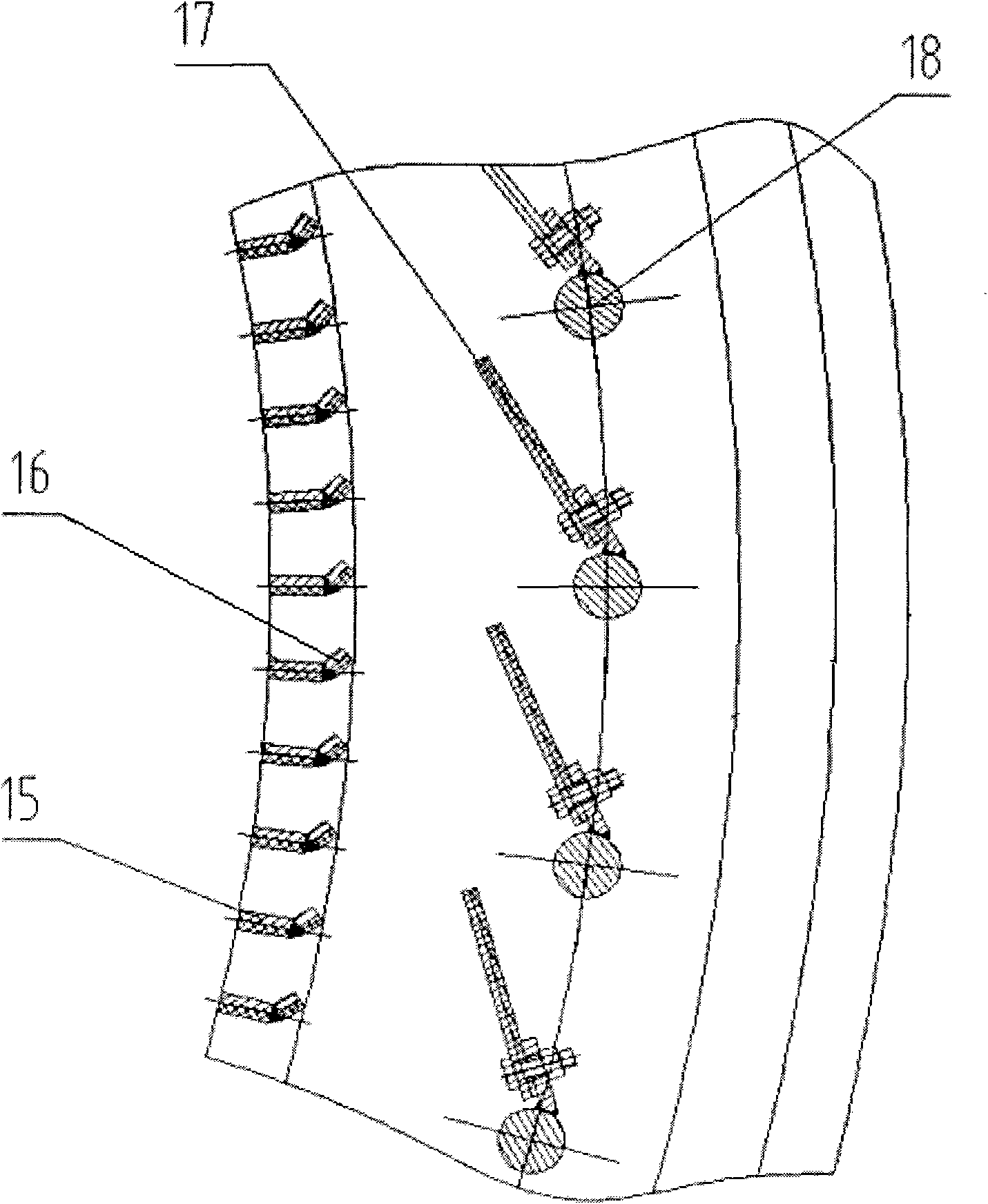

[0024] figure 1 The high-efficiency powder separator shown mainly includes two parts: the inside of the machine body and the outside of the machine body. The inside of the machine body is provided with a main shaft 10, a stator 6, a rotor 4, a lower rotor cone 3 and a coarse material collection cone 2. The outside of the body is provided with a transmission part 9, an upper cover body 8, a frame 7, a middle cover body 5 and a lower cover body 1 from top to bottom.

[0025] The upper cover body 8 is a hollow truncated conical structure with an upper part and a lower circle, and the lower...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com