Highly antibacterial and anti-fingerprint spraying-free polycarbonate alloy material and preparation method thereof

A polycarbonate and alloy material technology, applied in anti-fingerprint spray-free polycarbonate alloy material and its preparation, high antibacterial field, can solve the problems of modification effect discount, component interference, cost increase, etc., to achieve stable and wide range. The effect of spectrum antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

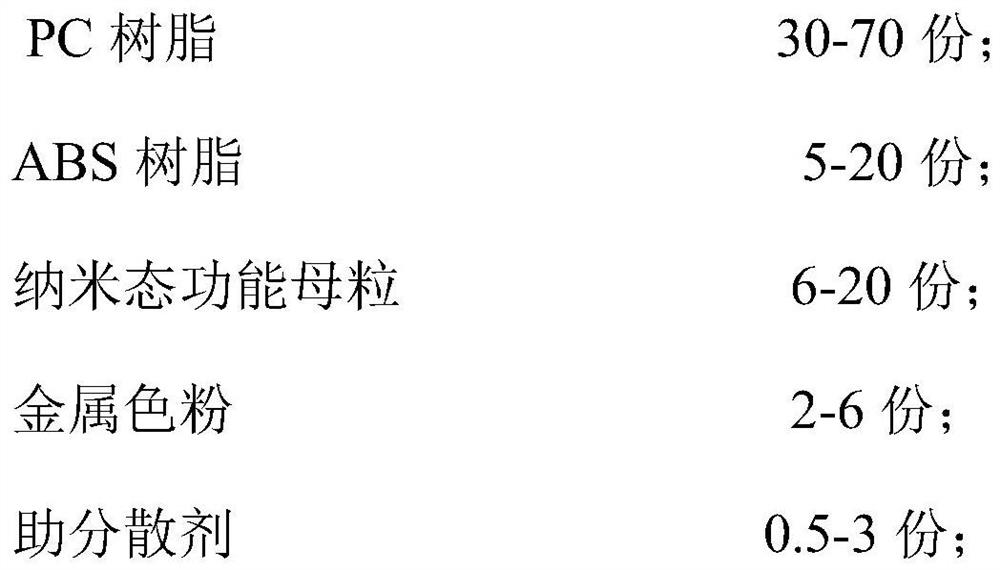

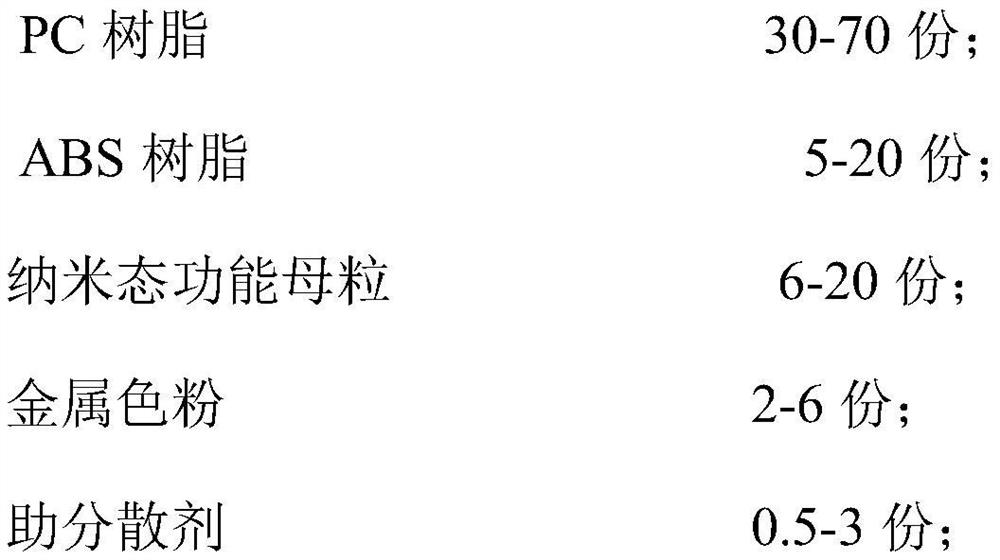

Method used

Image

Examples

Embodiment 1

[0045] Weigh the MBS multi-block copolymer and nano-state mesoporous material according to the ratio of Example 1 in Table 1, mix them uniformly and put them into a closed reactor, vacuumize the reactor and fill it with inert nitrogen to protect it to normal pressure , then heated to 180°C and kept at a constant temperature, stirred at a constant speed of 150 rpm for 60 minutes, then added a certain proportion of high-efficiency antibacterial agents and lipophilic functional additives in sequence, continued to stir for 60 minutes, filled with nitrogen and pressurized, from the airtight The outlet at the bottom of the reactor leads out the molten blend, cools it, and cuts it into pellets to obtain nano-state functional masterbatches.

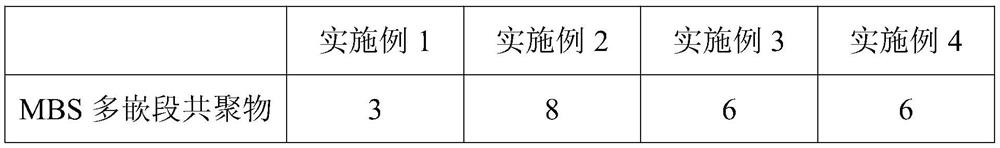

[0046] Formulation table (unit: gram) of nano state functional masterbatch of table 1

[0047]

[0048]

Embodiment 2

[0050] Weigh the MBS multi-block copolymer and nano-state mesoporous material according to the ratio of Example 2 in Table 1, mix them evenly and put them into a closed reactor, vacuumize the reactor and fill it with inert nitrogen to protect it to normal pressure , then heated to 180°C and kept at a constant temperature, stirred at a constant speed of 150 rpm for 60 minutes, then added a certain proportion of high-efficiency antibacterial agents and lipophilic functional additives in sequence, continued to stir for 60 minutes, filled with nitrogen and pressurized, from the airtight The outlet at the bottom of the reactor leads out the molten blend, cools it, and cuts it into pellets to obtain nano-state functional masterbatches.

Embodiment 3

[0052] Weigh the MBS multi-block copolymer and nano-state mesoporous material according to the ratio of Example 3 in Table 1, mix them uniformly and put them into a closed reactor, vacuumize the reactor and fill it with inert nitrogen to protect it to normal pressure , then heated to 180°C and kept at a constant temperature, stirred at a constant speed of 150 rpm for 60 minutes, then added a certain proportion of high-efficiency antibacterial agents and lipophilic functional additives in sequence, continued to stir for 60 minutes, filled with nitrogen and pressurized, from the airtight The outlet at the bottom of the reactor leads out the molten blend, cools it, and cuts it into pellets to obtain nano-state functional masterbatches.

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| impact strength | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com