Powder separating machine for cement raw material, clinker and slag vertical type roller mill

A technology of cement raw materials and vertical roller mill, which is applied in the direction of separating solids from solids with airflow, solid separation, chemical instruments and methods, etc. It can solve the unreasonable width and height of the classification area and affect the stable operation of the system for a long time , unable to form a stable graded force field and other problems, to achieve the effect of compact structure, high cost performance, and convenient manufacturing and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

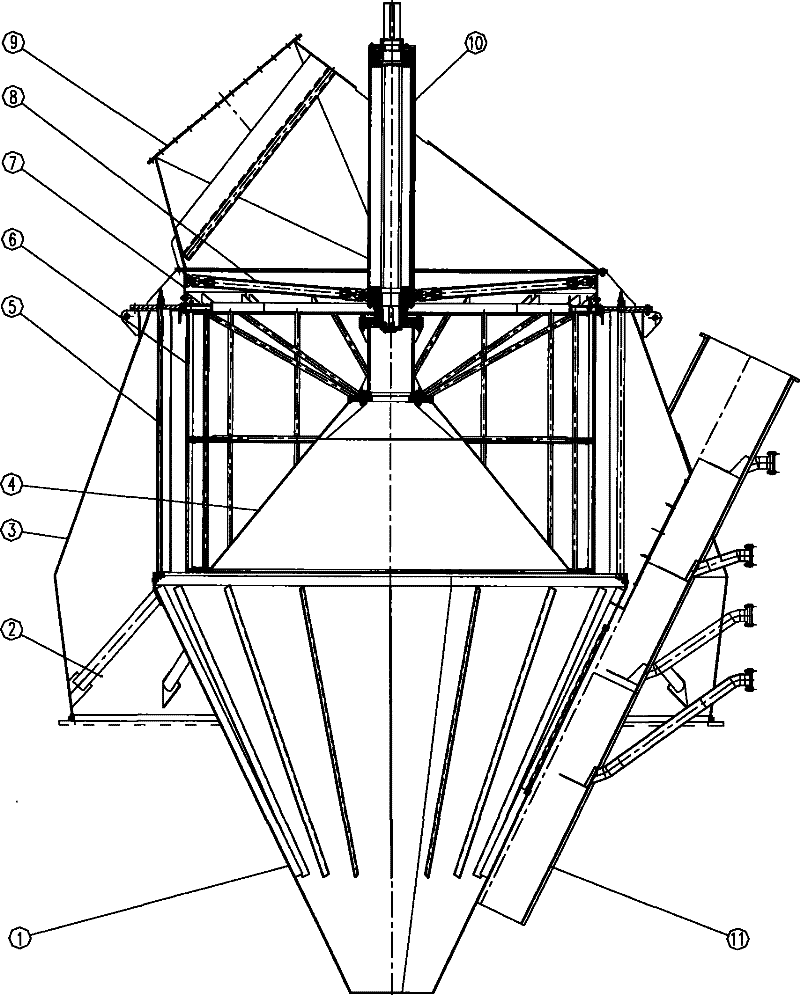

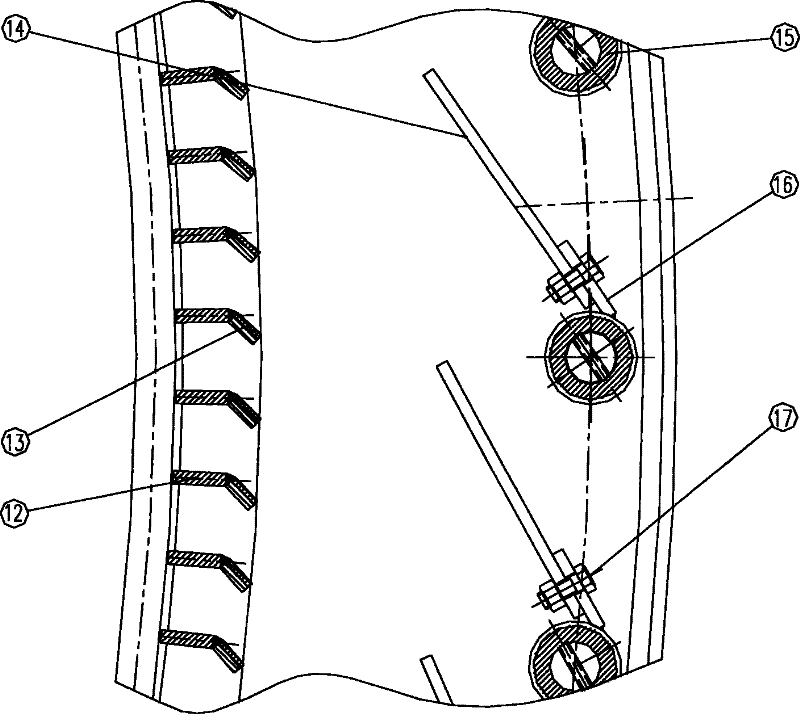

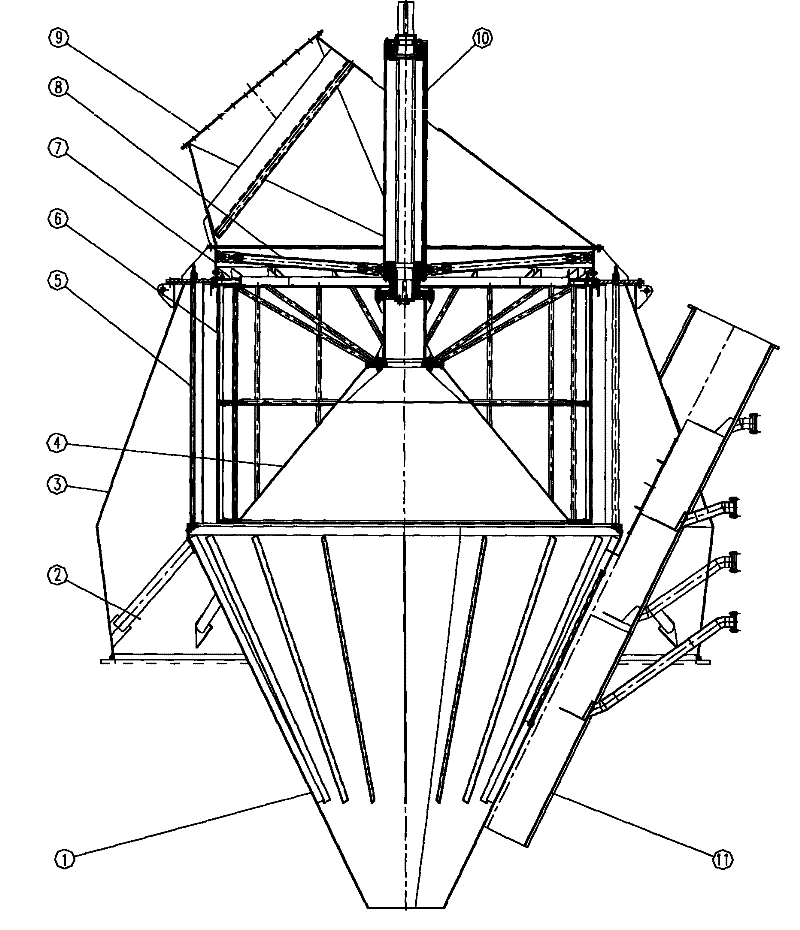

[0018] pass figure 1 , 2 It can be seen that: the separator for cement raw material, clinker and slag vertical roller mill of the present invention, its main structure is composed of an external upper casing 9, a middle casing 7, a lower casing 3 and a feed chute 11 and the internal main shaft 10, main shaft outer tube strut 8, rotor 6, rotor lower cone 4, and coarse material collection cone 1; wherein the upper shell 9 is a hollow truncated cone structure with upper and lower circles, and the upper shell 9 Bolt connection between the lower flange and the upper flange of the middle shell 7; the middle shell 7 is hollow cylindrical, the bolt connection between the lower flange of the middle shell 7 and the upper flange of the lower shell 3; It is a hollow frustum-shaped structure with thin ends and thick middle; the center line of the feed chute 11 forms a certain angle with the longitudinal center line of the powder separator, and the feed chute 11 is located outside the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com