A kind of preparation method of positive electrode slurry of lithium ion battery

A lithium-ion battery, positive electrode slurry technology, applied in battery electrodes, batteries, positive electrodes and other directions, can solve the problems of reducing the viscosity of the colloid, the effect is not obvious, and the colloid is deteriorated at high temperature, and achieves improved adhesion, good dispersion effect, avoid damaging effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

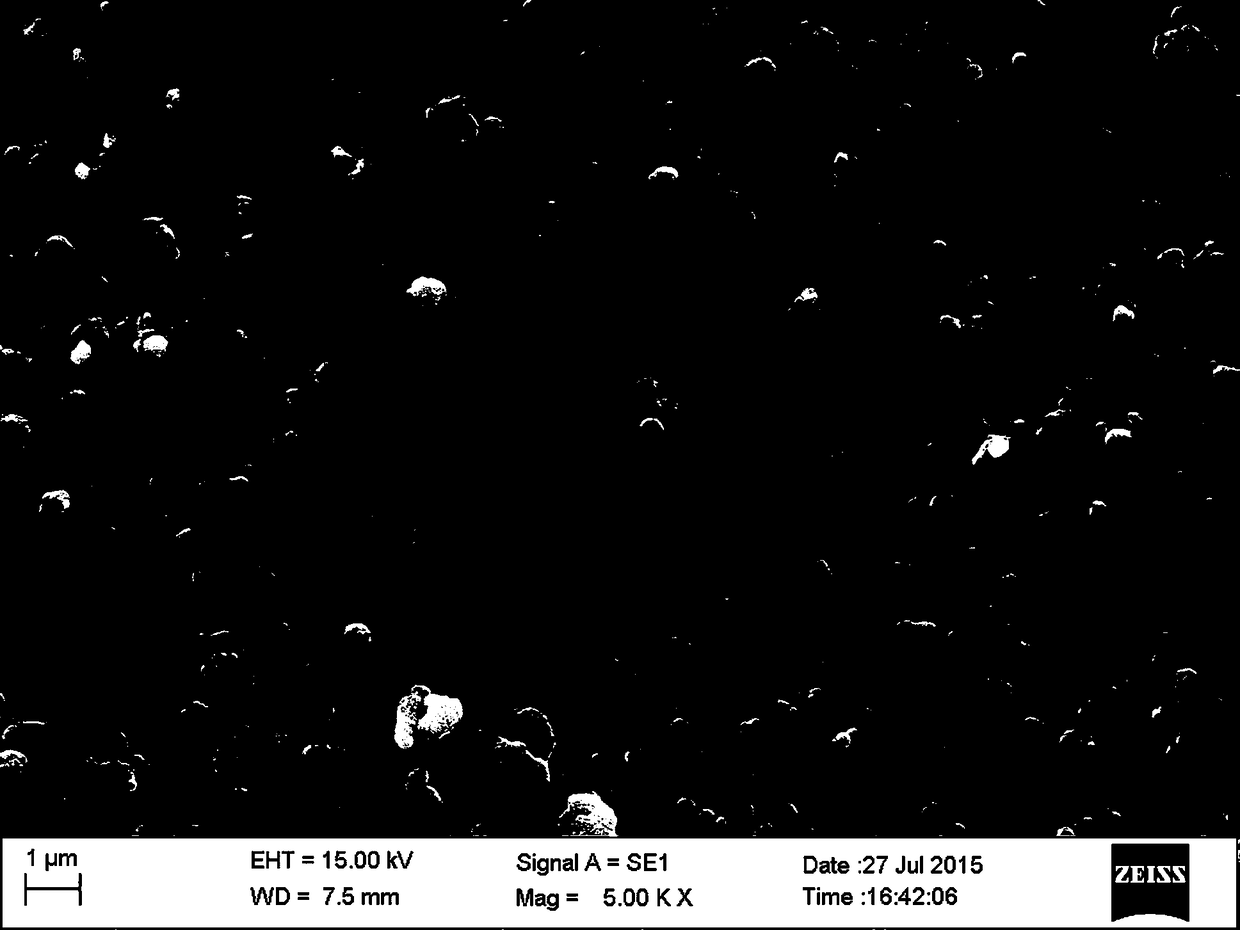

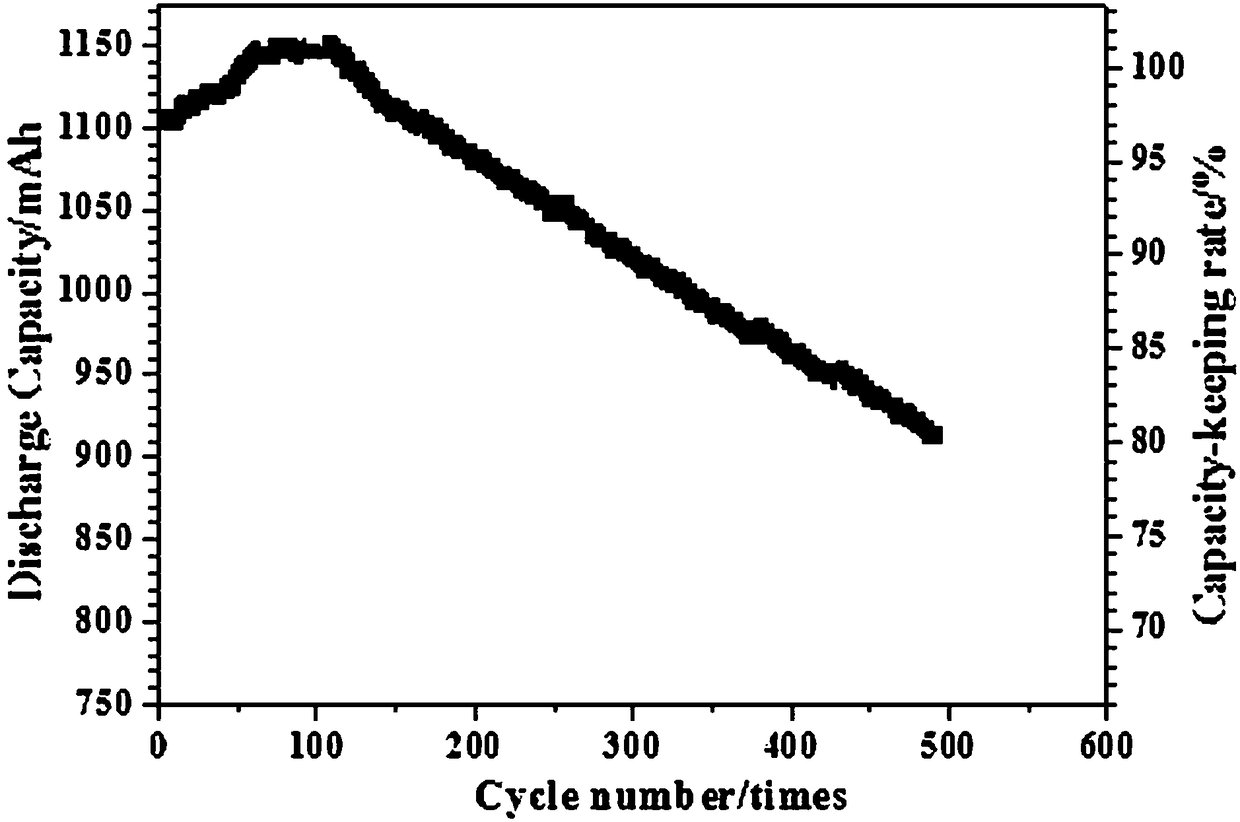

[0022] Firstly, lithium iron phosphate XCL01-2CPZ material (made by Shandong Jinggong Electronic Technology Co., Ltd.), single-walled carbon nanotube CNT300 (Beijing Deke Daojin Technology Co., Ltd.), graphene (Beijing Deke Daojin Technology Co., Ltd.) and Conductive carbon black Super-p (Beijing Haiwei Jiaye Chemical Products Co., Ltd.) was vacuum-baked in a vacuum oven XHX8-121A (Shenzhen Xinyuren Technology Co., Ltd.) at 120±3°C for 8 hours, and the vacuum degree was ≤-0.095MPa . Polyvinylpyrrolidone PVPK90 (Guangzhou Batai Chemical Co., Ltd.) and polyvinylidene fluoride HSV900 (Arkema) were baked in a vacuum oven XHX8-121A (Shenzhen Xinyuren Technology Co., Ltd.) at 80±3°C for 8h under vacuum , Vacuum degree ≤ -0.095MPa. After baking, cool down naturally to below 40°C for later use. After baking, polyvinylidene fluoride and N-methylpyrrolidone were mixed at a mass ratio of 8:92 and added to a planetary mixer HY-DLH (100L) (Guangzhou Hongyun Machinery Co., Ltd.) for 2 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com