Adhesive interlining machining equipment

A technology of processing equipment and adhesive interlining, which is applied in the direction of coating, liquid coating device on the surface, etc., can solve the problems of difficult control of the quality of hot melt adhesive powder, waste of hot melt adhesive powder, high production cost, etc. Achieve the effects of easy operation, improved uniformity, and improved utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

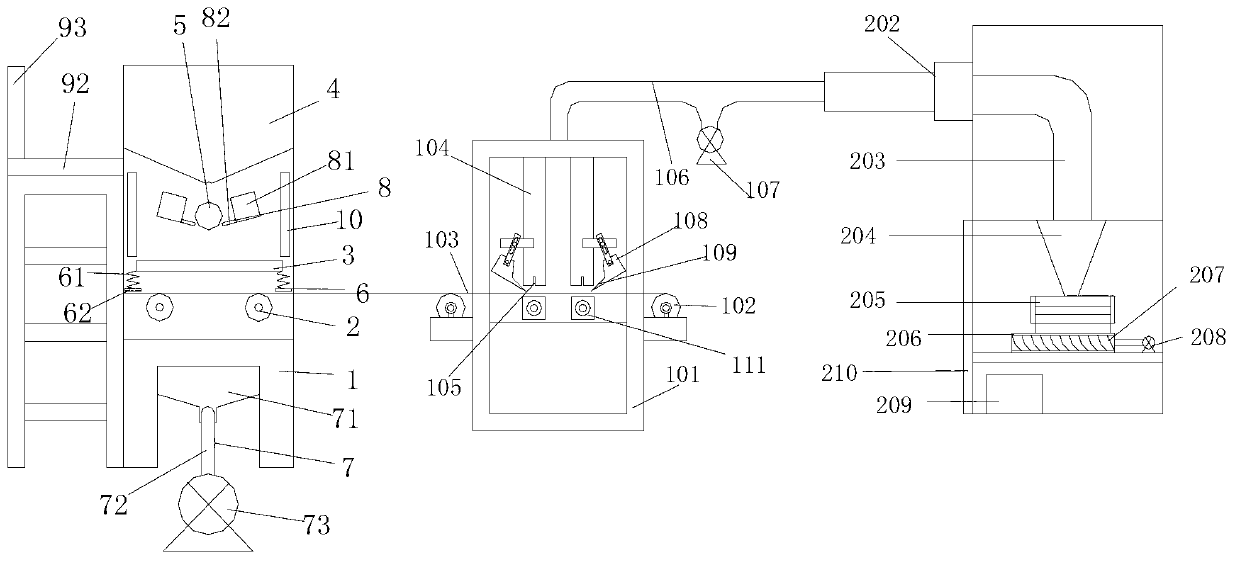

[0024] refer to figure 1 , the present invention is an adhesive interlining processing equipment, which sequentially includes a powder spreading device, a powder blowing device and a powder output device.

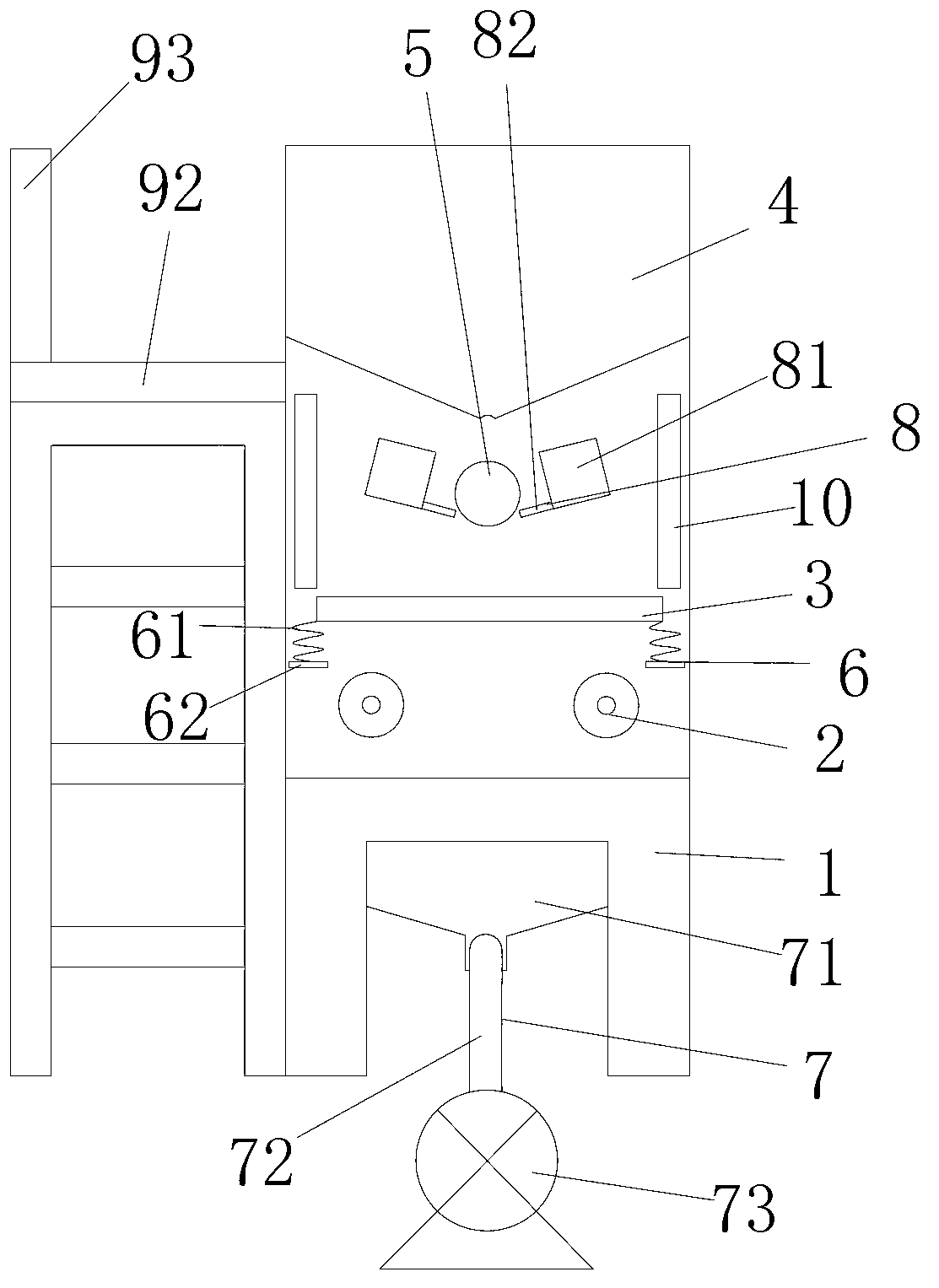

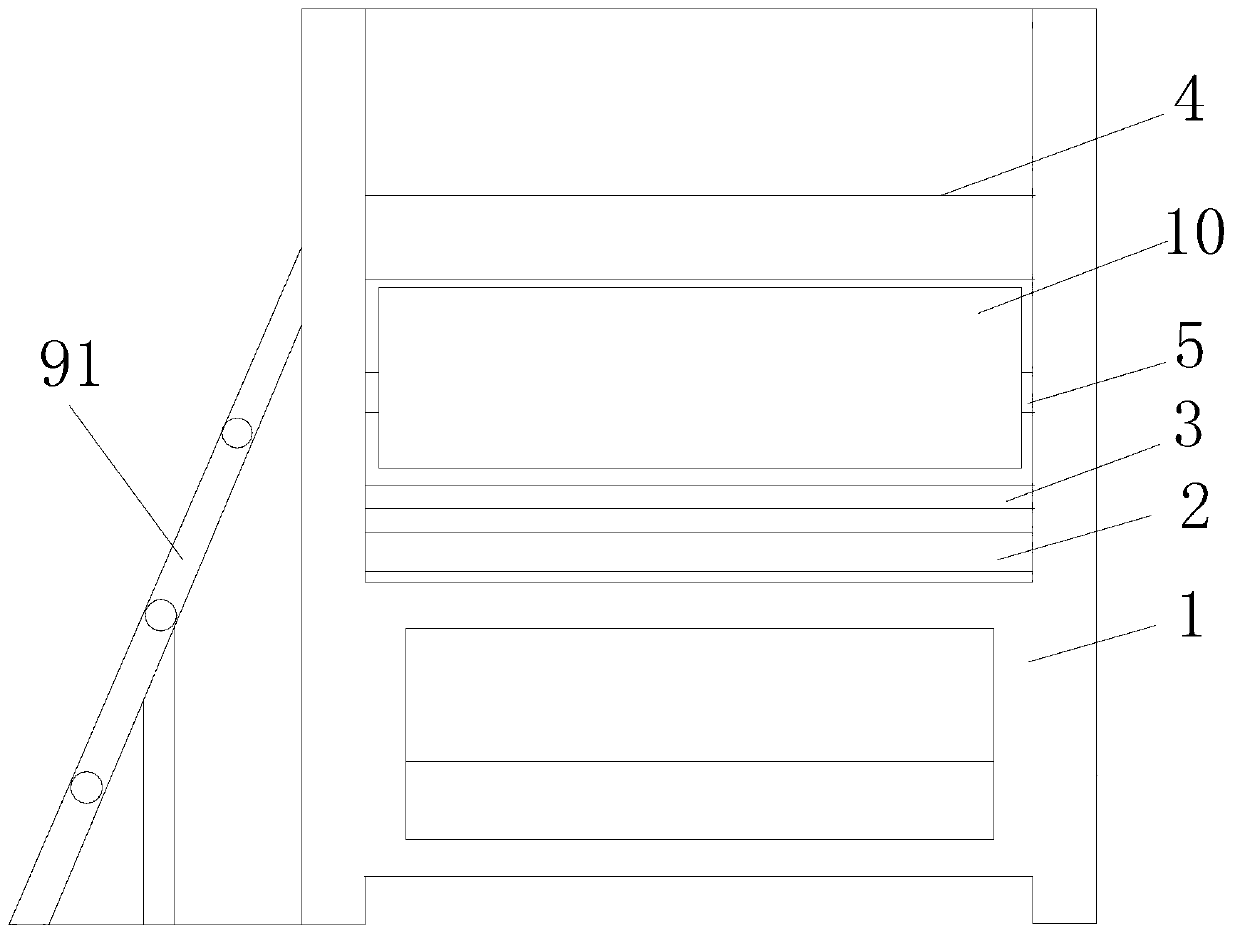

[0025] refer to figure 2 and image 3 , the powder spreading device includes a first frame 1, a first cloth guide roller 2 installed on the first frame 1, a blanking assembly, a hopper 4, a powder collecting mechanism 7, an operating platform 9 and a partition door 10, so The hopper 4 is located on the top of the first frame 1, the unloading assembly is located between the hopper 4 and the first cloth guide roller 2, the powder collecting mechanism 7 is located below the first cloth guide roller 2, and the operation platform 9 is located on the rear side of the first frame 1, and partition doors 10 are installed on the front and rear sides of the blanking assembly. When performing powder spreading operations, close the front and rear partition doors 10 to prevent the hot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com