Moisture absorption and quick-drying uvioresistant fabric and production method thereof

An anti-ultraviolet, moisture-absorbing and quick-drying technology, used in fabrics, perforated fabrics, textiles, etc., can solve the problems affecting wearing comfort, high ventilation performance, and stuffy heat.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

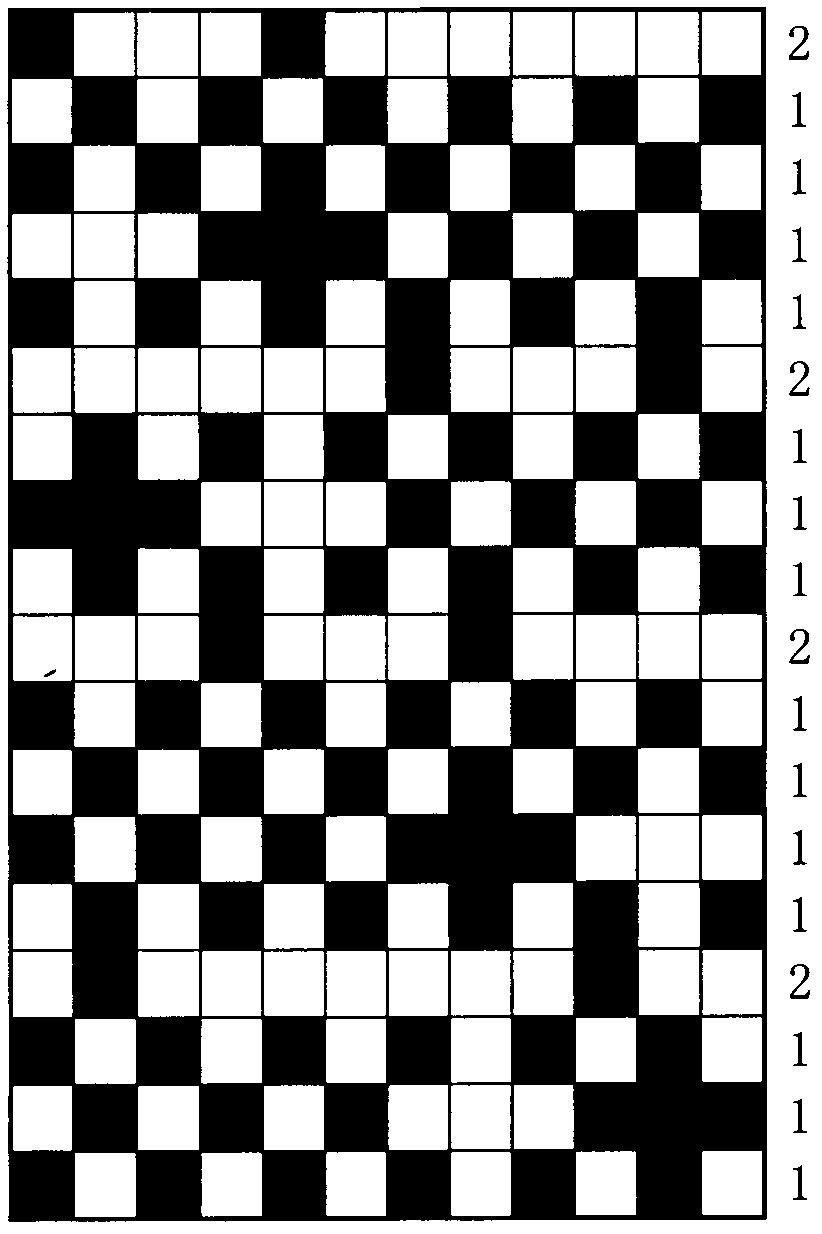

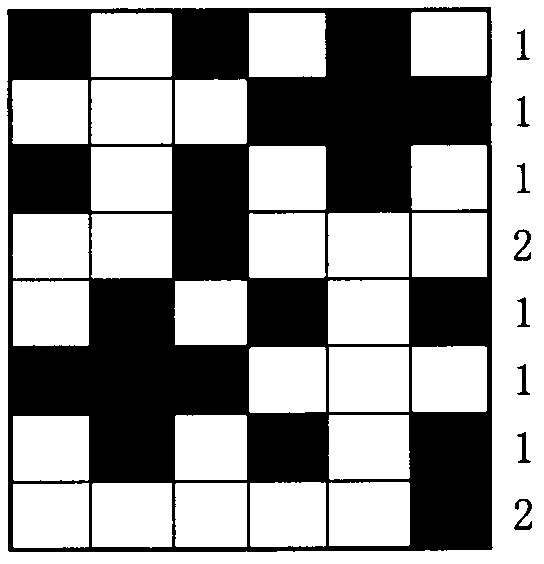

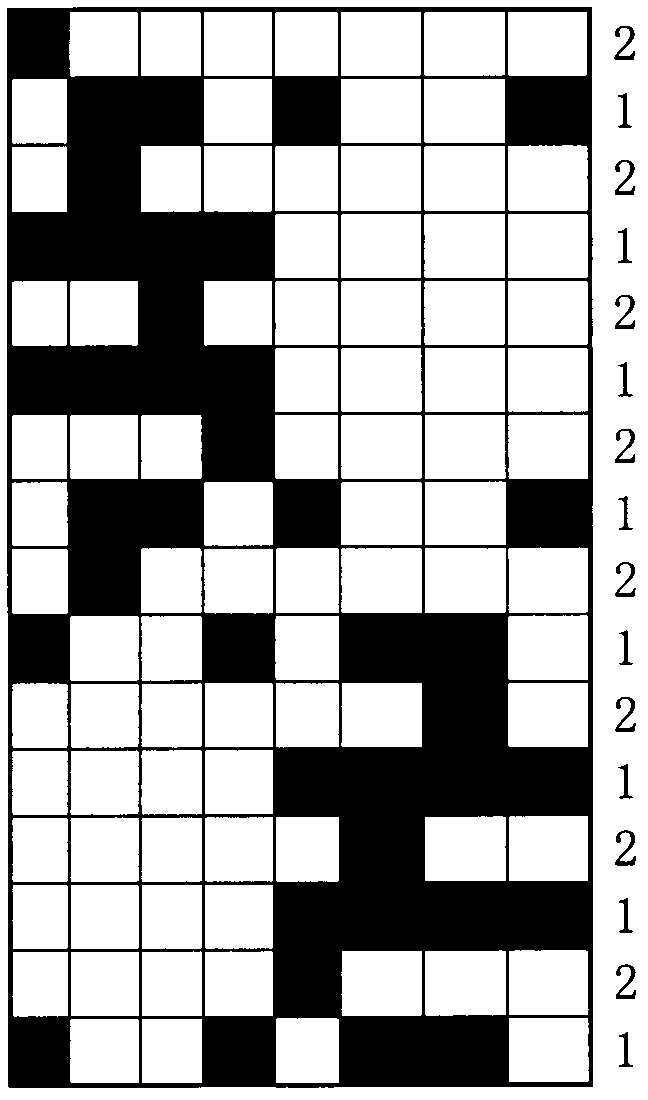

Image

Examples

Embodiment 1

[0031] A moisture-absorbing and quick-drying anti-ultraviolet fabric, the warp, surface weft and inner weft are all made of 50D-48f-shaped cross-section anti-ultraviolet polyester yarn with a titanium dioxide content of 2.5wt%, and the surface weft and inner weft are arranged in a 7:2 cycle Carry out weaving, the organization is through-hole weft double weave, obtains the gray cloth that cover coefficient is 1500, the gained gray cloth obtains the finished product after scouring and degreasing, dyeing, finishing and finalizing. Liquid flow dyeing is used for dyeing, and the width of the fabric is set according to 2% of the existing width when finishing and finalizing, and the cloth is dropped by vibrating.

[0032] The resulting product has the advantages of good moisture absorption and quick drying, good UV resistance, and comfortable wearing. The ventilation volume of the fabric is 52cc / cm 2 .s, UPF value of 61, water evaporation rate of 99% in 12 minutes, water absorption h...

Embodiment 2

[0034] A moisture-absorbing and quick-drying anti-ultraviolet fabric, the warp yarn adopts 75D-36f-round cross-section anti-ultraviolet polyester yarn with a twist of 600T / M and a titanium dioxide content of 6.5wt%, and its content is 52% by weight; the surface weft adopts 75D- 72f-ordinary circular section polyester yarn, its content is 36% by weight; the inner weft adopts 75D-36f-special-shaped section anti-ultraviolet polyester yarn with a titanium dioxide content of 2.0wt%, its content is 12% by weight, and the surface weft It is woven with the inner weft in a 3:1 arrangement, and the weave is a through-hole and weft double weave to obtain a gray cloth with a cover factor of 2300. The gray cloth obtained is then refined to remove oil, dyed, water-absorbed, and finished. Among them, liquid flow dyeing is used for dyeing, and the amount of water-absorbing agent is 2.0g / L. When finishing and shaping, the width is set according to 2% of the existing width, and the cloth is drop...

Embodiment 3

[0037] A moisture-absorbing and quick-drying anti-ultraviolet fabric, the warp yarn adopts 75D-36f-common circular cross-section polyester yarn with a twist of 1200T / M, and its content is 48% by weight, and the surface weft and inner weft are both twisted with 600T / M, Titanium dioxide content is 6.5wt% 75D-36f-shaped cross-section anti-ultraviolet polyester yarn, its content is 52% by weight, the surface weft and the inner weft are woven according to the arrangement 1: 1, and the organization is a double weave of through-hole weft, which is obtained The gray cloth with a coverage factor of 1989 is refined and degreased, dyed, water-absorbed, finished, and shaped to obtain a finished product. Among them, liquid flow dyeing is used for dyeing, and the amount of water-absorbing agent is 2.0g / L. When finishing and setting, the width is set according to 3% of the existing width, and the cloth is dropped by vibration.

[0038] The resulting product has the advantages of good moisture ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Evaporation rate | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| Evaporation rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com