Winter heating system for poultry house

A warm air system and poultry house technology, applied in poultry cages or houses, poultry industry, applications, etc., can solve the problems of slow heat dissipation, uneven hot air circulation, impractical production, etc., to achieve reasonable structure and avoid chicken flocks Cold, good effect of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

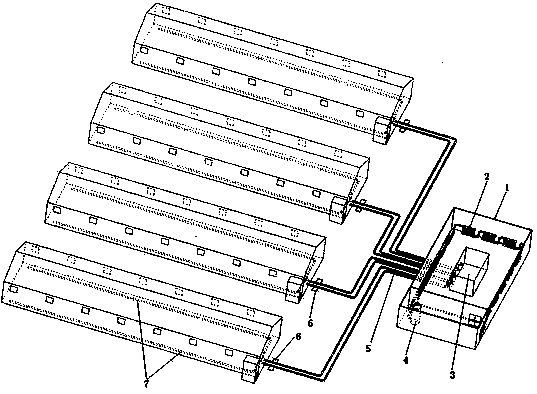

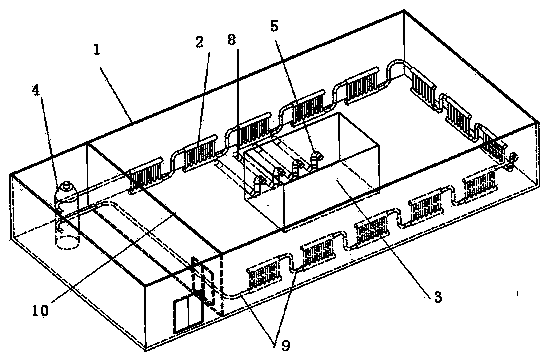

[0009] A specific embodiment of the present invention is a heating system for poultry houses in winter, which includes a boiler 4 and a radiator 2. A boiler is arranged in a transparent greenhouse 1. The boiler communicates with the radiator through a hot water pipe 9. The boiler and the radiator A partition wall 10 can be provided between the sheets, and potted flowers and plants, etc. can also be placed in the greenhouse to ensure the purification of the air in the greenhouse. A pool 3 is provided in the transparent greenhouse, and the inside of the pool is provided with a ventilation duct 5. The inlet of the ventilation duct The position of the tuyere is higher than the position of the water surface in the pool, and the air duct is provided with a blower fan 8, which communicates with the air supply duct 7 of the hen house, and the connection position between the air supply duct and the air duct is provided with a lifting fan 6.

[0010] The present invention can build the a...

Embodiment 2

[0012] A specific embodiment of the present invention is a winter heating system for a poultry house, which includes a boiler and a radiator. A boiler is arranged in a transparent shed. The boiler communicates with the radiator through a hot water pipe, and the boiler and the radiator can be There is a partition wall, and potted flowers and plants can also be placed in the greenhouse to ensure the purification of the air in the greenhouse. There is a pool in the transparent greenhouse, and there is a ventilation duct inside the pool. The air inlet of the ventilation duct is higher than the water surface in the pool. A fan is provided in the ventilation duct, and the ventilation duct communicates with the air supply duct of the chicken house, and a lifting fan is provided at the connection position between the air supply duct and the ventilation duct; the ventilation duct described in this embodiment is placed outside the transparent greenhouse. Buried at 70-80 centimeters undergro...

Embodiment 3

[0014] A heating system for a poultry house in winter, which includes a boiler and a radiator. A boiler is installed in a transparent shed. The boiler communicates with the radiator through a hot water pipe. A partition wall can be provided between the boiler and the radiator. Potted flowers and plants can be placed in the greenhouse to ensure the purification of the air in the greenhouse. There is a pool in the transparent greenhouse. There is a ventilation duct inside the pool. The air inlet of the ventilation duct is higher than the water surface in the pool. The fan, the ventilation pipe is connected with the air supply pipe of the chicken house, and a lifting fan is provided at the connection position between the air supply pipe and the ventilation pipe; the pool described in this embodiment is provided with a water inlet and a water outlet; it can ensure that the water in the pool Replace it in time to improve the cleanliness. At the same time, there is an air filter in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com