Yarn supply device capable of simulating warp beam

A technology for simulating warp beams and thread supply, which is applied to auxiliary equipment for weaving, textiles, textiles, and papermaking, etc. It can solve the problems of limited fabric width, limited warp beam length, and cumbersome weaving process, so as to avoid limited length and fabric The effect of uneven surface and simplified textile process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

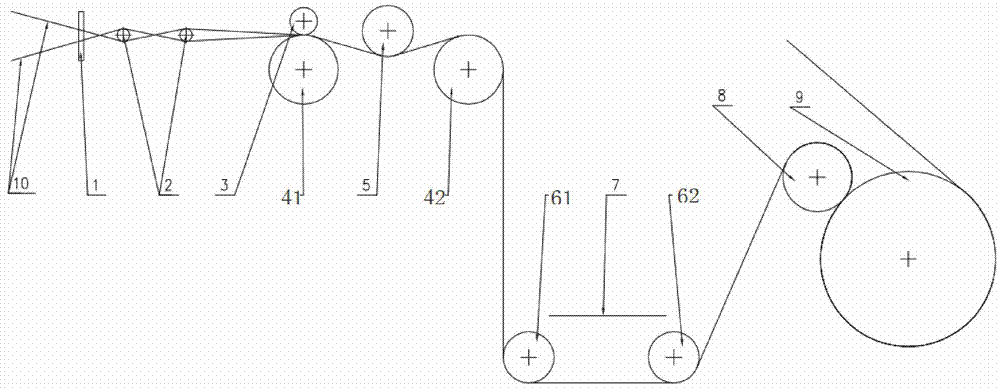

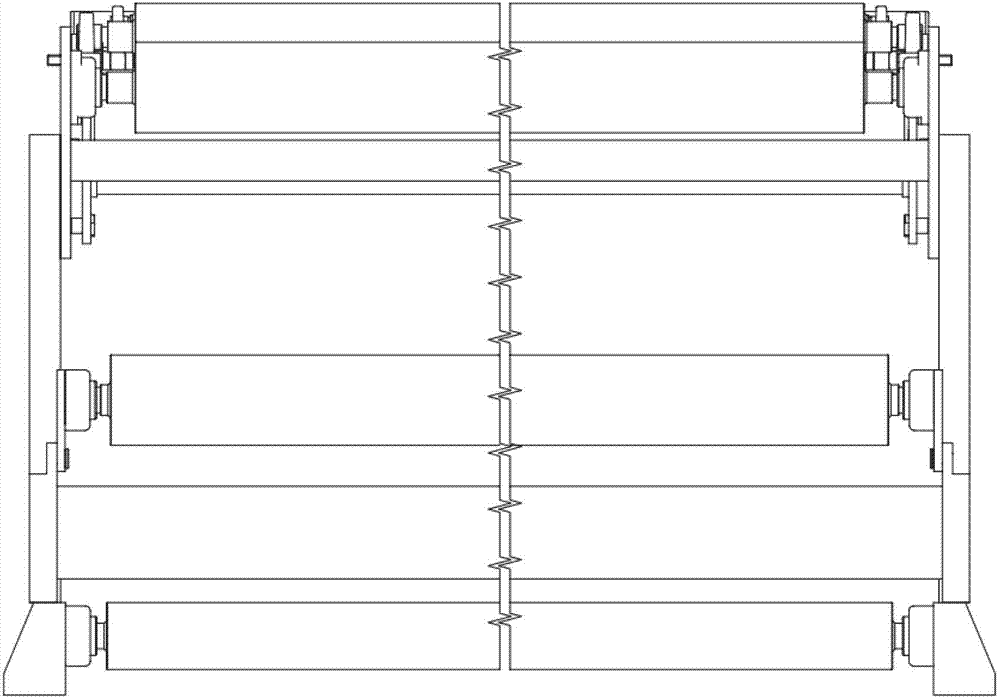

[0024] The inventive spirit of the present invention can be better understood in conjunction with the drawings and specific embodiments. The provided drawings are only used to show a specific implementation of the wire supply device of the present invention, and do not limit its size, proportion, position, etc. Improvements, transformations, etc. made by those skilled in the art on this basis still belong to the protection scope of the present invention.

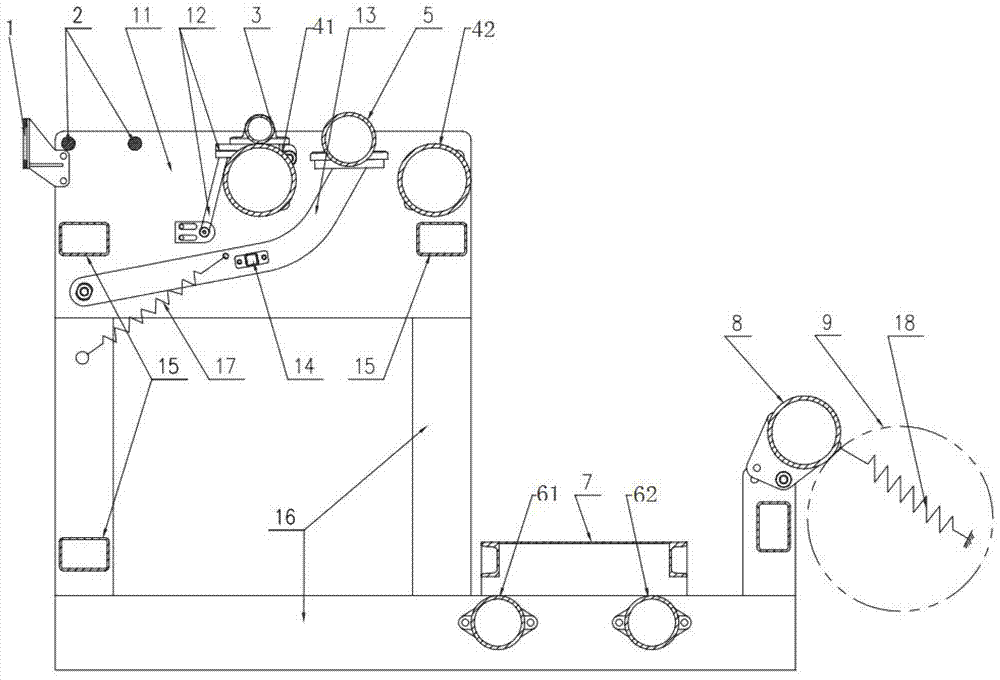

[0025] Reference attached figure 1 , the wire supply device of the present invention includes a frame, and the main body of the frame is a support frame 16 composed of two vertical plates in the vertical direction and a horizontal bottom plate in the bottom horizontal direction, and a wall plate 11 at the top of the support frame, wherein the threading Frame 1, two twisted wire bars 21,22, upper crimping roller 3, the first conductor roller 41, tension roller 5, the second conductor roller 42 are all fixedly installed on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com