Device for adjusting the stroke of a tamping beam of a road finishing machine

A technology for repairing machines and tamping beams, which is applied in the field of stroke devices to achieve the effects of reducing wear, small amplitude and simple connection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

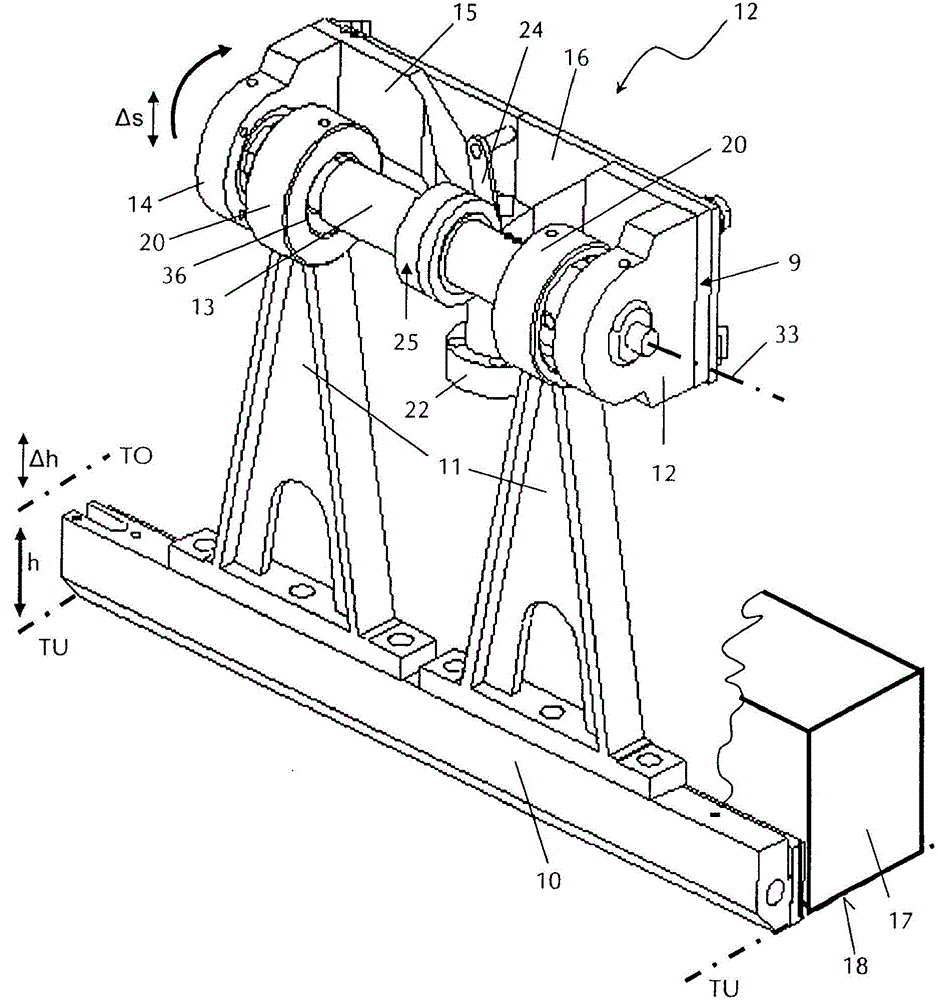

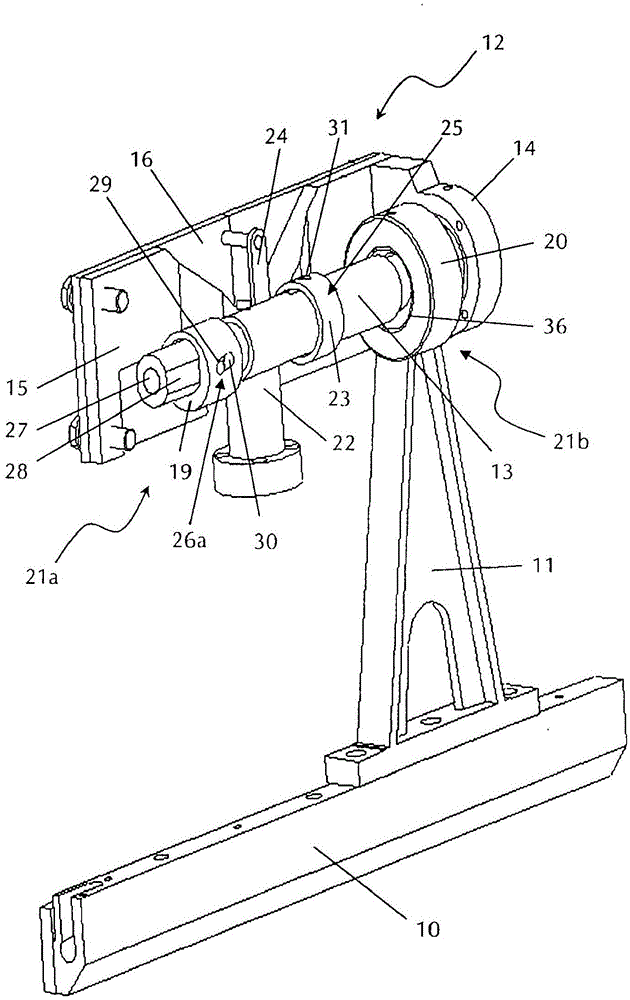

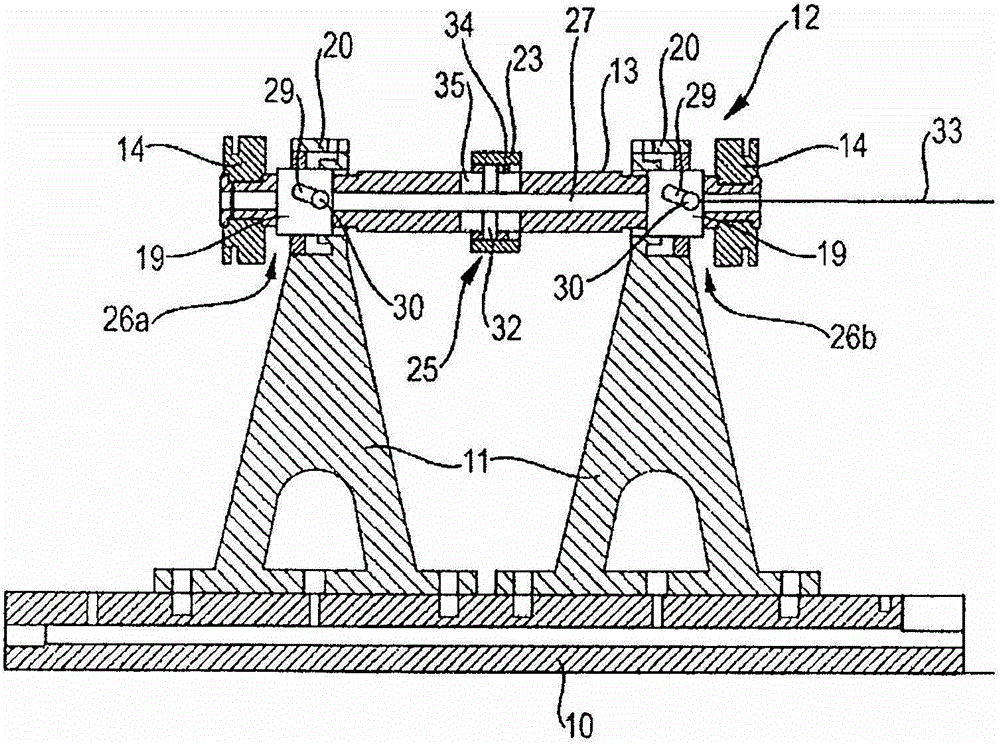

[0020] according to figure 1 and 2 , a tamping beam 10 of a road finishing machine (not shown) is connected to a mechanism 12 via two push rods 11 for adjusting the stroke of the tamping beam 10 . The mechanism 12 has a cam drive with a camshaft 13 fastened to a camshaft bracket 15 via a bearing block 14 . The camshaft bracket 15 is arranged displaceably in the height direction on a base frame 16 of a known paving screed (not shown) of the road finishing machine. Camshaft 13 is provided with two eccentric cams 19 ( figure 2 ), each eccentric cam 19 cooperates with the pivot cap 20 on the push rod 11 . The pivot cap 20 is provided with concentric bearing holes.

[0021] The paving screed has a slide 17 whose bottom surface 18 is substantially flat and which rests on the material to be paved. The tamping beam 10 is located in front of the slide 17 in the direction of travel of the road finishing machine. The tamping beam 10 , driven by the camshaft 13 , vibrates oscillati...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com