Toilet bowl

A toilet, flushing water technology, applied in flushing toilets, urinals, water supply devices, etc., can solve the problems of unavoidable excessive water spray, strong whirlpools, and increased production costs of toilet seats.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

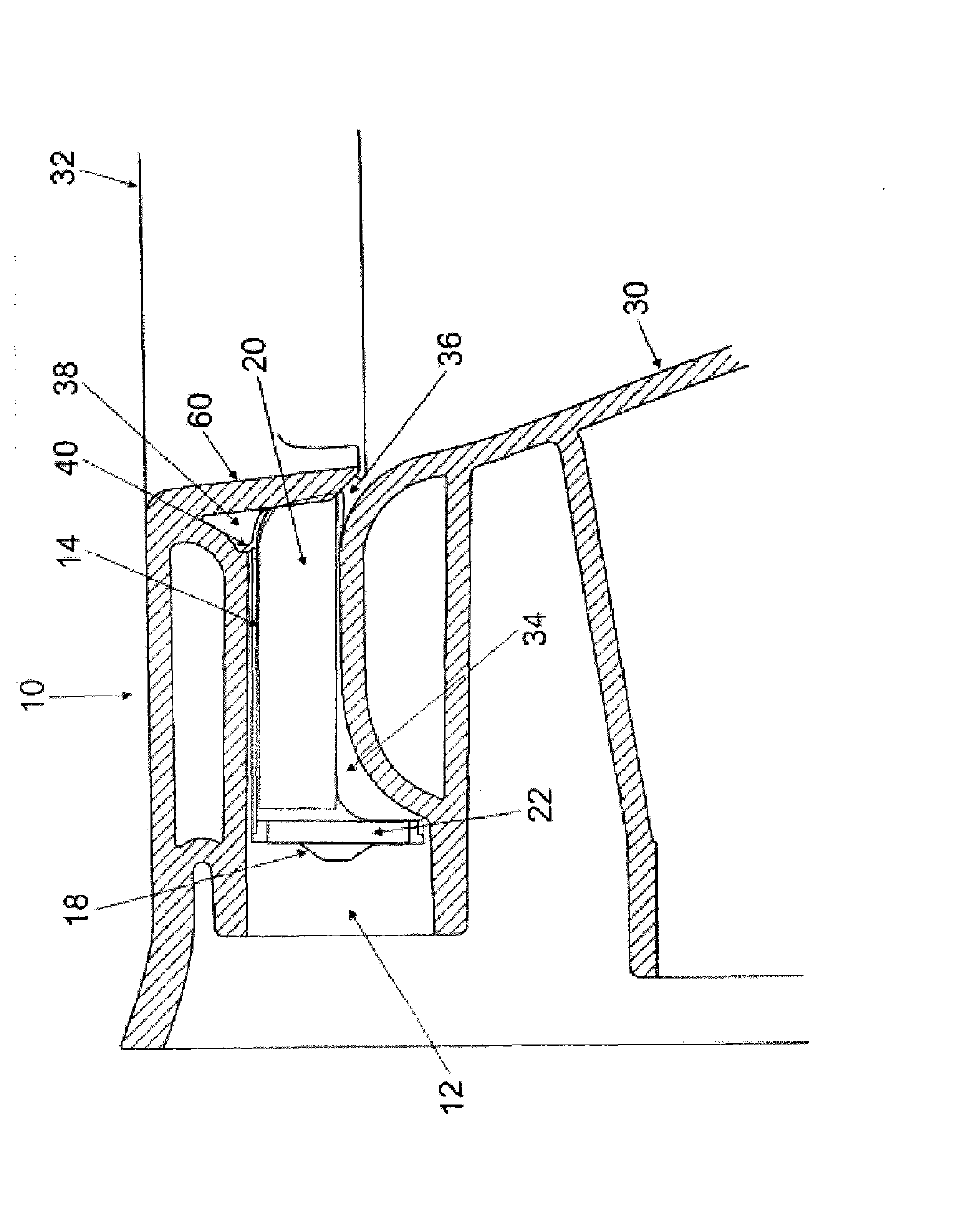

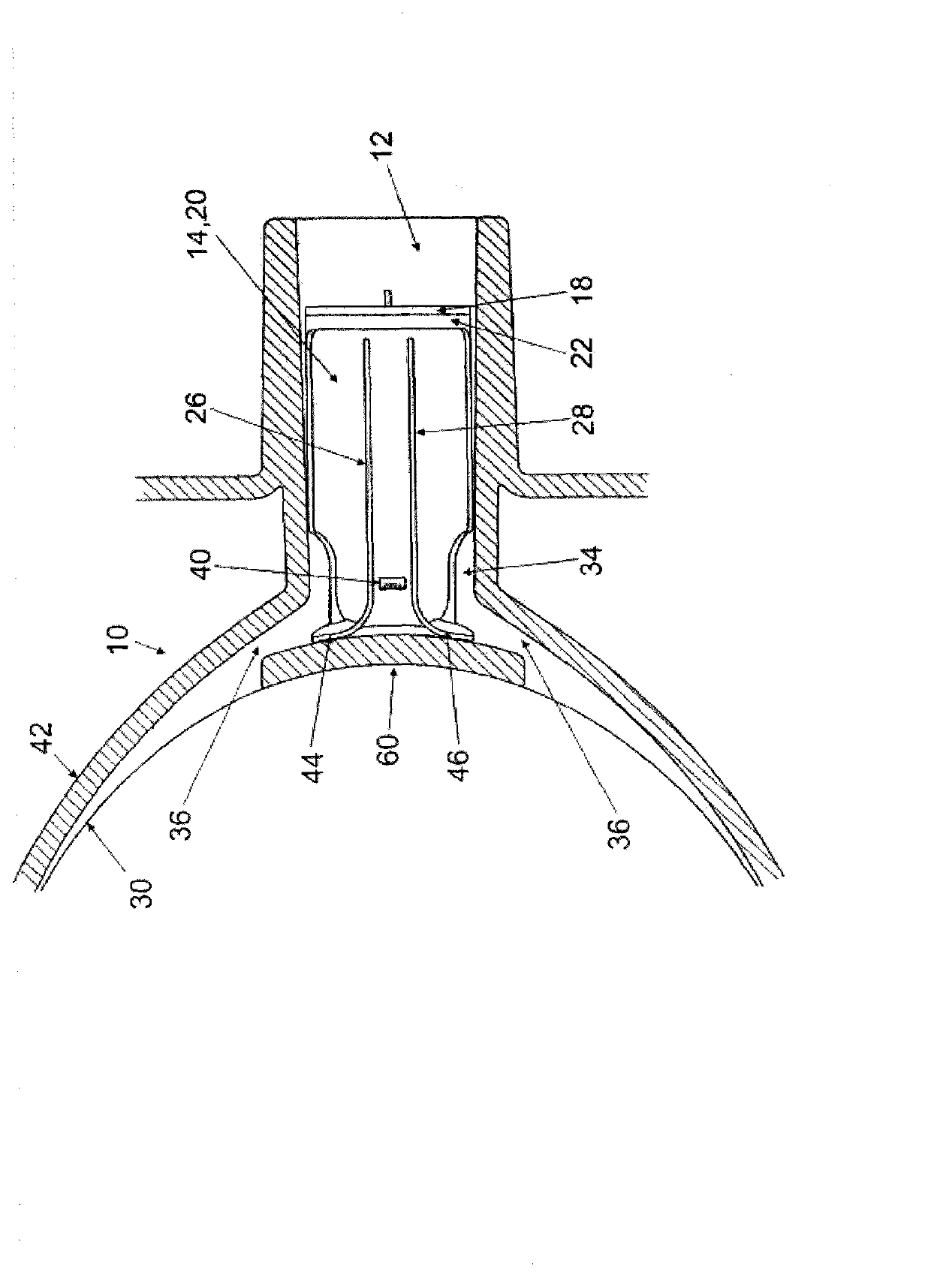

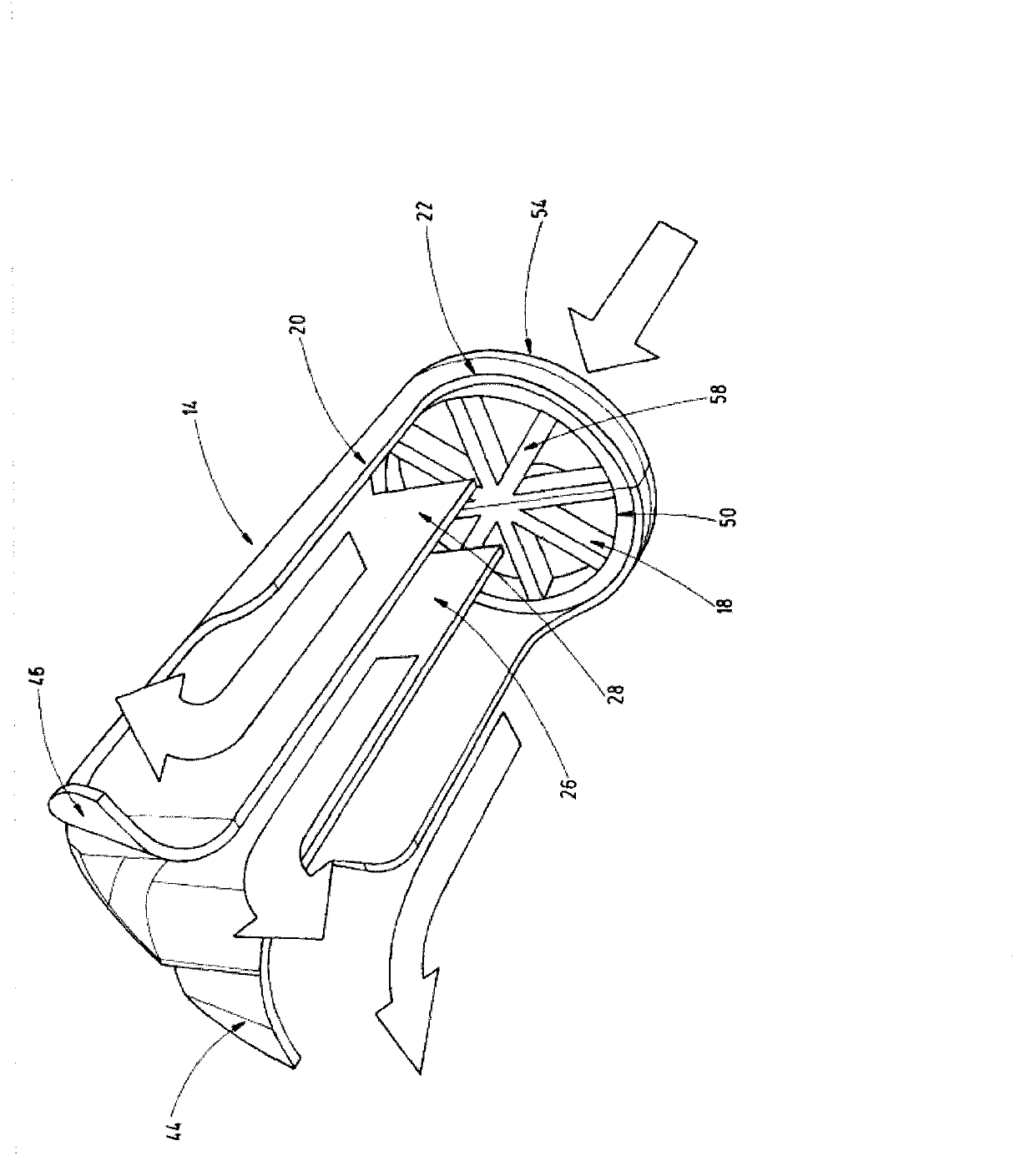

[0029] figure 1 and 2 Shown are schematic partial cross-sectional views of a toilet seat 10 with a flush water distributor 14 and a flush water flow restriction 18 according to the invention. figure 1 The cut plane in the extends vertically, while figure 2 The cut plane extends horizontally. The toilet seat 10 has an inner wall surface 30 and an outer wall surface 42 . The flushing water flows through the flushing water inlet 12 into the flushing water distributor 14 and is divided there into three different channels. These channels are formed by the shell surface of the main body 20 , the first inner wall 26 and the second inner wall 28 . especially if figure 2 As shown, the inner walls 26 , 28 have curved regions 44 and 46 in the region facing the inner wall surface 30 , which deflect the flushing water towards the lateral outflow opening 36 . The flushing water in the intermediate channel between the inner walls 26, 28 passes through another especially in the figur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com