Double-layer fireproof heat-preservation mold plate type wall body

A technology of fire prevention and heat preservation and formwork, which is applied to walls, building components, buildings, etc., can solve the problems of high risk of high-altitude operations, poor seismic performance, and easy collapse, so as to improve the seismic capacity and safety performance and reduce the threshold of building technology , Convenient handling and construction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

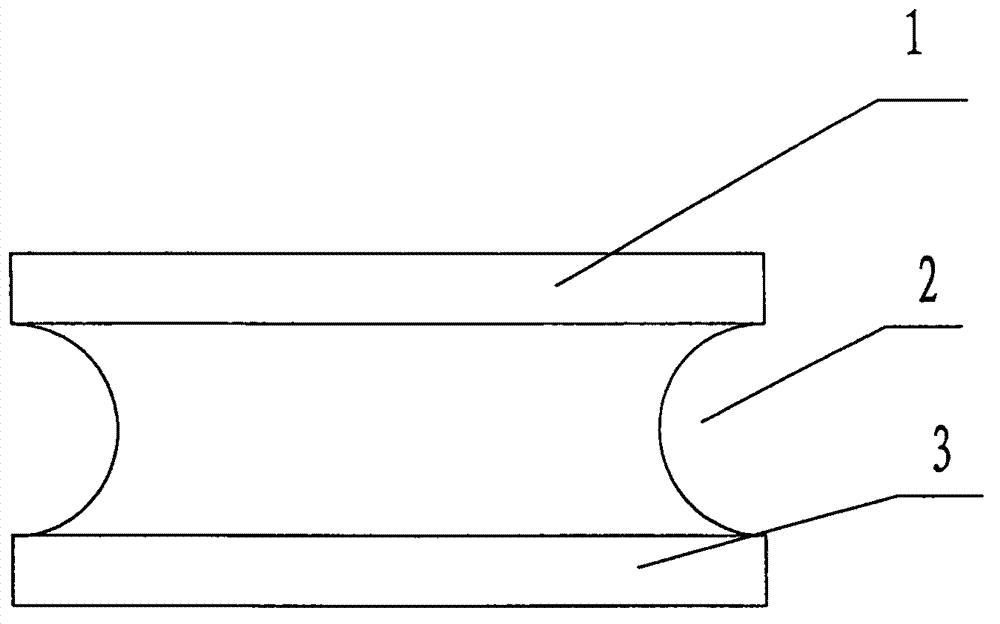

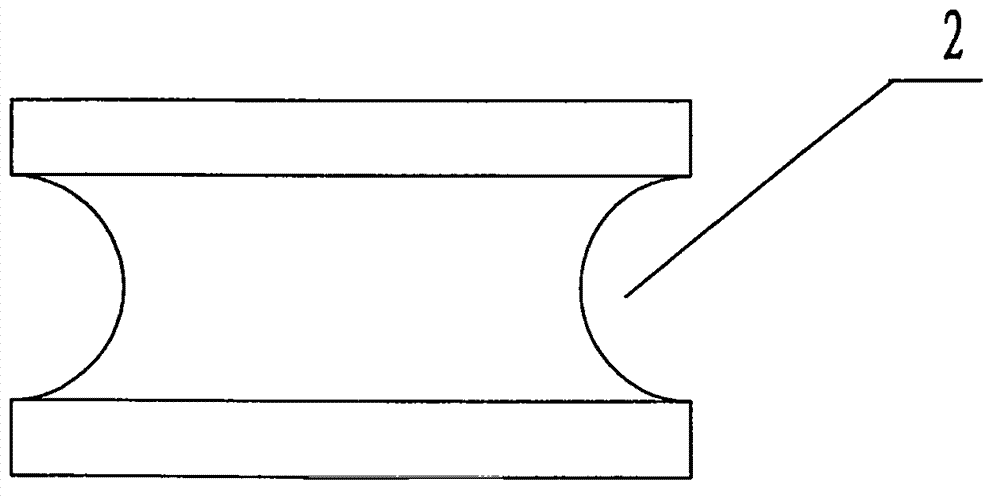

[0018] Embodiment 1, the shape of the front plate 1 and the rear plate 3 is a square or a rectangle close to a square, the front plate 1 and the rear plate 3 are fixedly connected, and there is a groove around the periphery between the front plate 1 and the rear plate 3 2. The groove bottom cross section of the groove 2 is arc-shaped or linear. Hasps 5 are provided around the front panel 1 and the rear panel 3 or on two opposite sides. The front plate 1, the back plate 3 and the fixed connections between them are made of fireproof and heat-insulating materials. When in use, when the present invention is spliced and fixed, the reinforcing bars 6 are bound or not bound, the reinforcing bars 6 are well connected with the reinforcing bars on the beams and columns, and then concrete is poured into the cavity formed between the front plate 1 and the rear plate 3 , that is, groove 2.

Embodiment 2

[0019] In the second embodiment, the shape of the front plate 1 and the rear plate 3 is a square or a rectangle close to a square, and there are no buckles 5 around the front plate 1 and the rear plate 3, and the surroundings are flat, and the rest are the same as in the first embodiment. .

Embodiment 3

[0020] Embodiment 3, the front plate 1 and the rear plate 3 are rectangular in shape, and a hole 4 is opened in the center of the fixed connection between the front plate 1 and the rear plate 3 . One or two or more holes 4 are fixedly connected between the front plate 1 and the back plate 3 , and grooves 2 are formed around the front plate 1 and the back plate 3 . The groove bottom cross section of the groove 2 is arc-shaped or linear. Hasps 5 are provided around the front panel 1 and the rear panel 3 or on two opposite sides. The front plate 1, the back plate 3 and the fixed connections between them are made of fireproof and heat-insulating materials. When in use, when the present invention is spliced and fixed, the reinforcing bars 6 are bound or not bound, the reinforcing bars 6 are well connected with the reinforcing bars on the beams and columns, and then concrete is poured into the cavity formed between the front plate 1 and the rear plate 3 , that is, groove 2 and h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com