Floor structure for mobile house

A technology for prefabricated houses and floors, applied in floors, building components, building structures, etc., can solve the problems of flammability, decay and low construction efficiency of plywood, and achieve easy production, convenient installation and disassembly, and high recycling rate. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

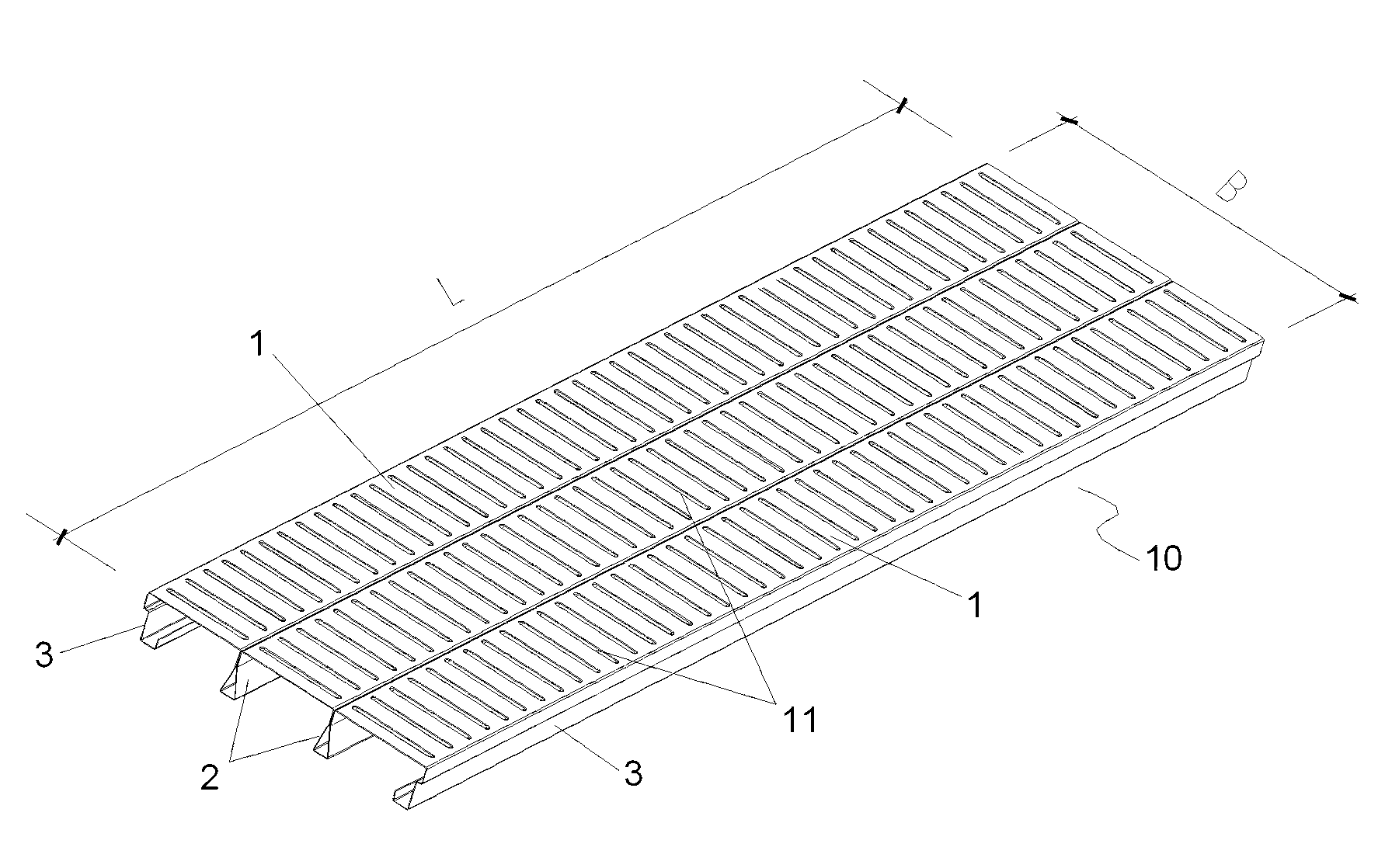

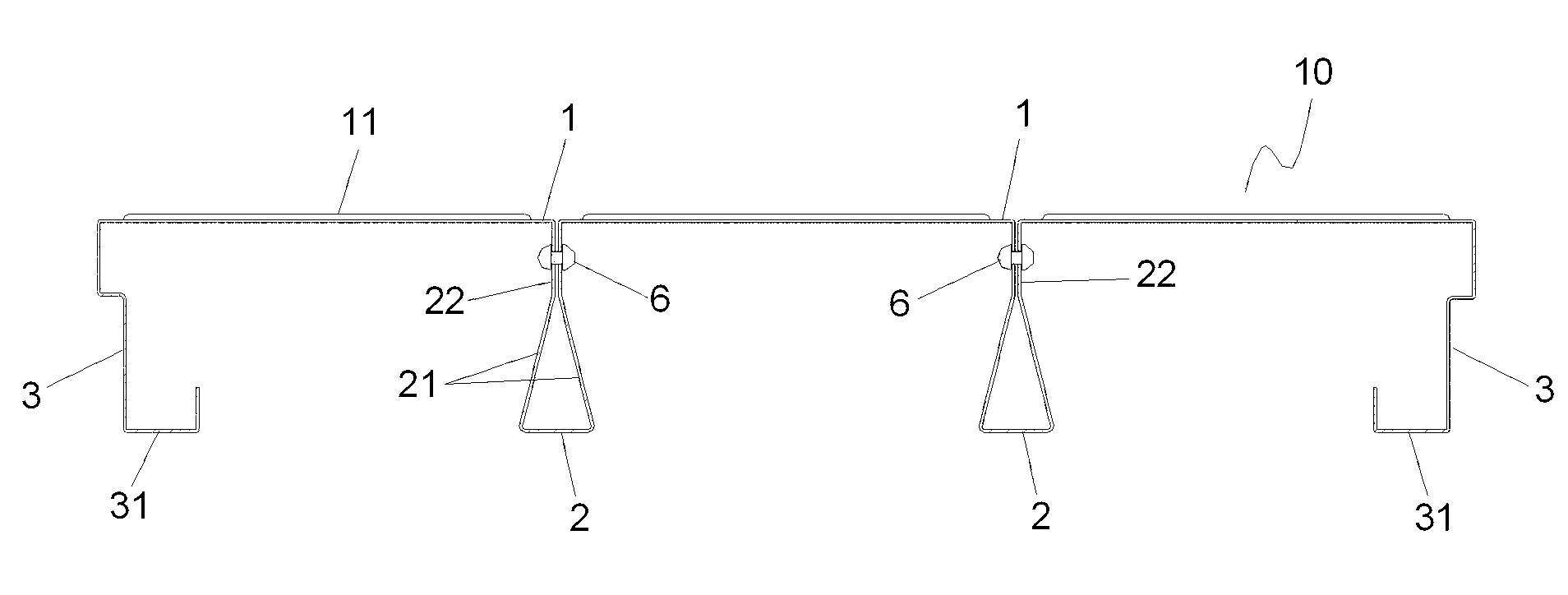

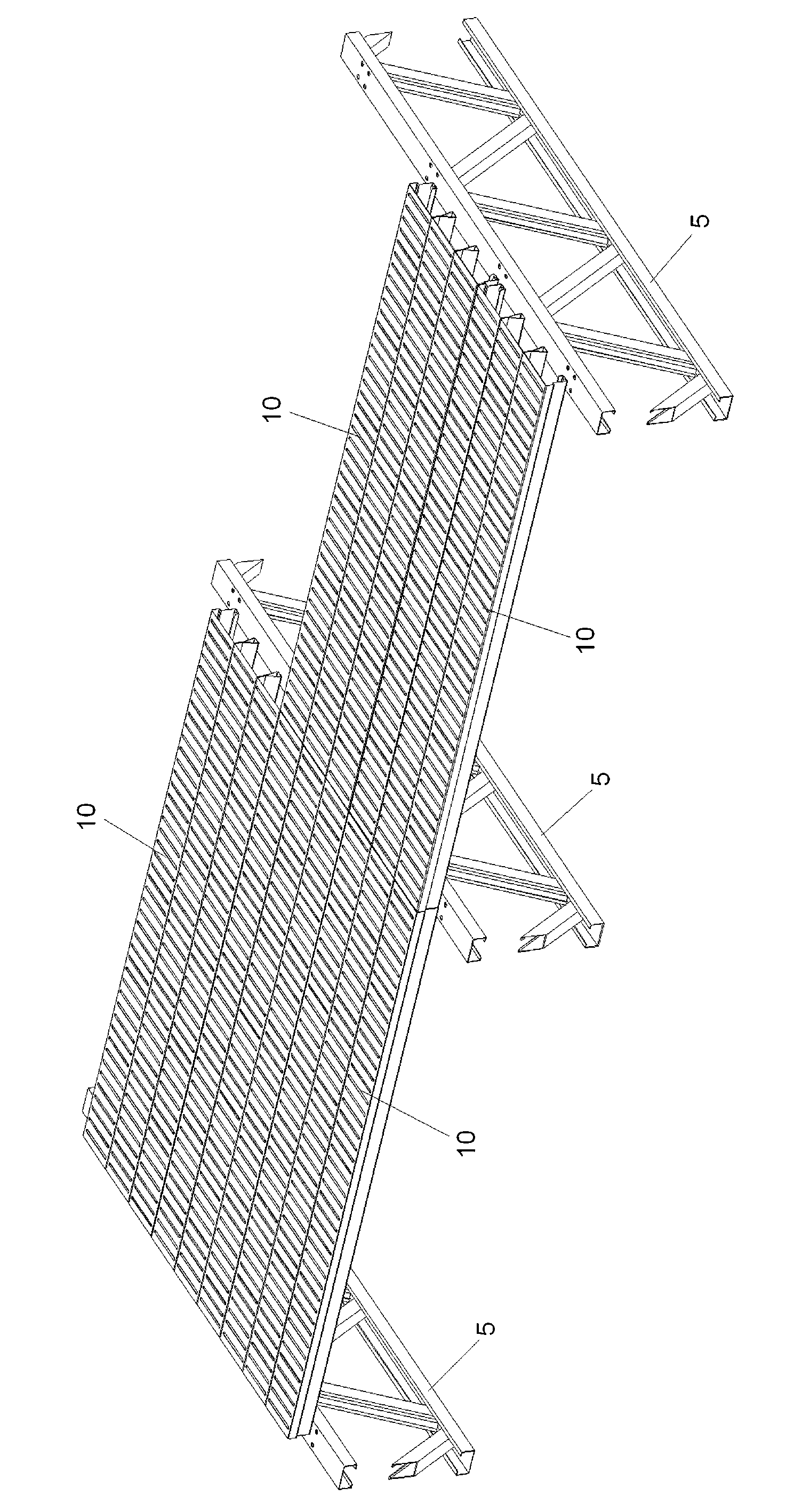

[0015] Such as image 3 As shown, the floor structure used in the prefab house of the present invention includes a plurality of floor units 10 erected and arranged on the floor beams 5 . Such as figure 1 and figure 2 As shown, the floor unit 10 is made of an integral plate and bent longitudinally, including: a horizontal panel 1 , a middle load-bearing rib 2 and a side load-bearing rib 3 . There are multiple horizontal panels 1 closely arranged on the top along the longitudinal direction, the middle load-bearing rib 2 is located below the junction of two adjacent horizontal panels 1 , and the side load-bearing ribs 3 are arranged on each floor unit 10 vertical sides of the .

[0016] Assuming that the length×width×height of the whole floor unit 10 after forming is L×B×H, then K=n×B, L=m×K. Among them, K is the standard modulus of the mobi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com