Auger bit with openable bottom baffle

An auger bit, open-close technology, applied in drill bits, drilling equipment, earth-moving drilling, etc., can solve the problems of shrinkage, difficulty in grouting, sand easily falling back into the hole, etc., and achieve the effect of avoiding shrinkage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention is further illustrated below by specific examples.

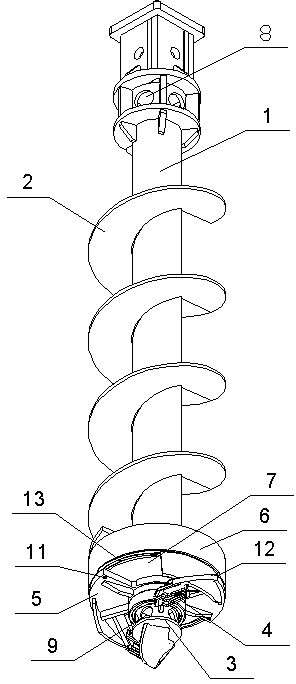

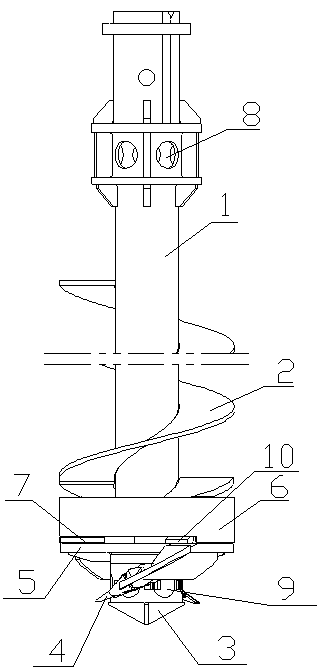

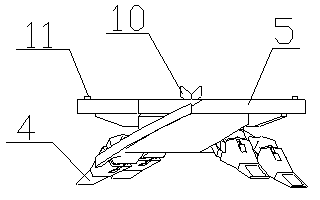

[0015] Such as figure 1 , figure 2 As shown, an auger bit with an openable and closable bottom baffle includes a drill body 1 with helical blades 2, a centering sleeve 3 and cutter teeth 4 arranged at the bottom of the drill body 1; it also includes a cylindrical Side baffles 6, middle baffles 7, and lower baffles 5; the cylindrical side baffles 6 are fixed on the bottom of the drill bit body 1, and the horizontal section shape of the lower baffles 5 is the same as that of the cylindrical side baffles 6. There is an opening on the surface, and the middle baffle 7 is rotatably connected to the top of the lower baffle 5, which is used to control the opening or closing of the opening of the lower baffle 5. The lower baffle 5 is rotatably connected to the bottom of the drill rod body 1 and is located on the cylindrical side baffle. 6 Bottom, the centering sleeve 3 is set under the lower baffle 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com