Selection method for reactor kingbolt to screw in rotation speed value

A technology of rotating speed and main bolt, which is applied in the mechanical field, can solve the problems such as the bad effect of the main bolt, achieve the effect of overcoming contingency and unpredictability, and improving reliability and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

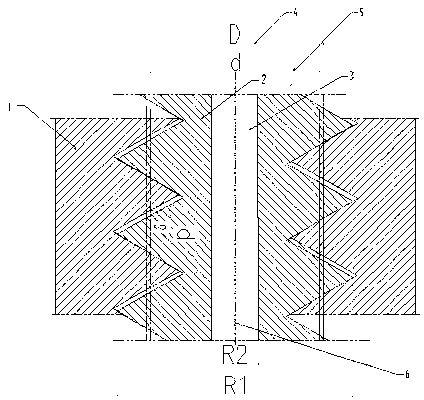

[0020] The specific embodiment of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0021] The method for selecting the rotating speed value of the main bolt of the reactor according to the present invention comprises the following steps:

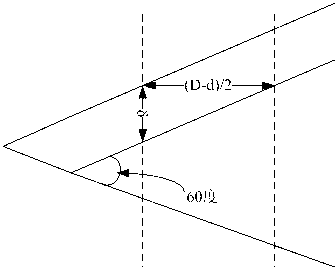

[0022] Step 1. Calculate and measure the moment of inertia J according to the geometric characteristics of the main bolt, measure and calculate the matching clearance δ and pitch P of the thread pair;

[0023] Step 2. According to n 2 =M*δ / K to calculate the screw-in speed, where K=2πJP / 3600, M is the allowable maximum torque of the reactor bolts, n is the screw-in speed, the unit is rev / min.

[0024] The present invention measures various parameters of the main bolt and the screw hole in step 1, and calculates the stuck time of the main bolt when it is screwed in. Due to the discrete individual differences in the manufacturing process of the components, the threads of the main...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com