Full Back Electrode Heterojunction Solar Cell

A solar cell, full-back electrode technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of large junction energy band difference, lower efficiency than expected, and high resistance, and achieve the effect of increasing open-circuit voltage and reducing short-circuit current.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

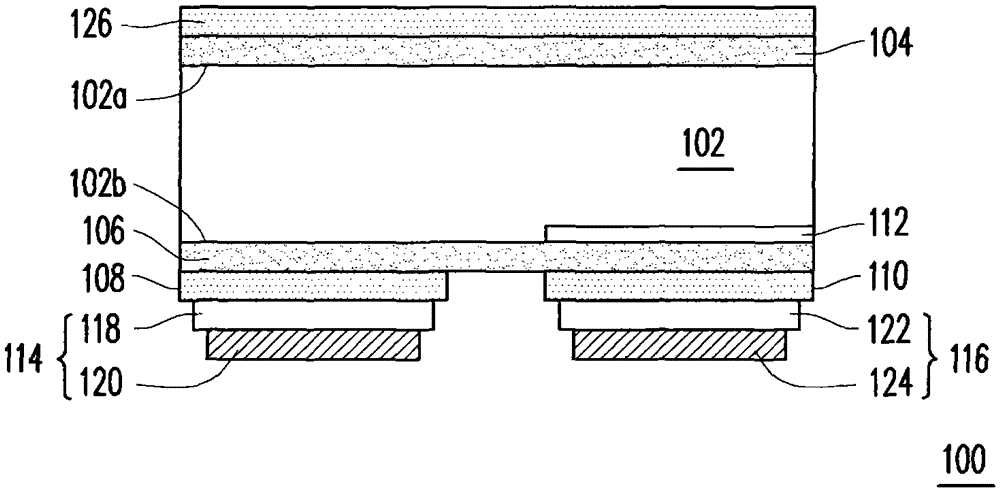

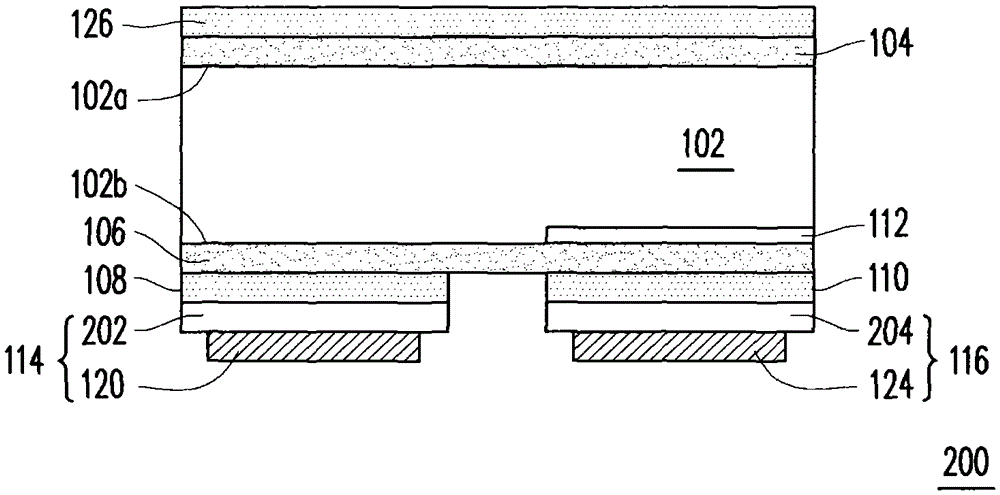

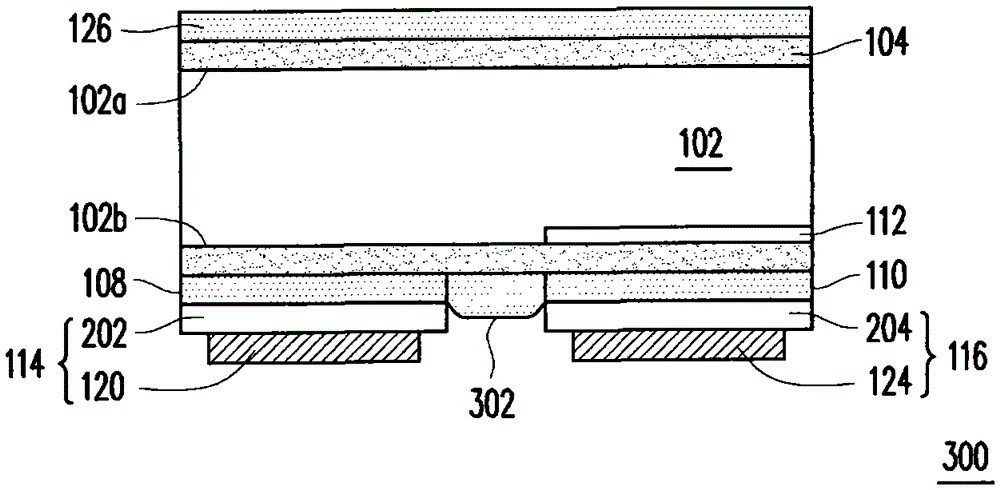

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0046] Please refer to the drawings to understand the present invention. However, the present invention can be implemented in many different forms and is not limited to the description of the embodiments. In the drawings, however, the sizes and relative sizes of layers and regions may not be drawn to scale for clarity.

[0047] When a member or layer is "located on another member or layer" herein, unless otherwise specified, it means that it may be directly located on another member or layer, or there may be an intermediate member or layer between the two. In addition, the text uses relative terms such as "on", "below" and similar spatial relative terms to describe the relationship between a component in the drawings and another (or more) components. However, the spatially relative terms may also include the orientation of the member in use or operation in a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com